- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- earth moving

Results for

Earth moving - Import export

KEBA FASTENINGS

Germany

are threaded bolts suitable for the automotive industry and heavy earth moving equipment. Able to endure heavy impact loads Uniformed case hardness to ensure strength and flexibility Precisely manufactured to fit perfectly on spring bushes

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The round tubes are manufactured from a coil that is bent and electric resistance welded (ERW). The forming process can be according to EN 10210, which foresees hot forming or cold forming followed by heat treatment, or according to EN 10219, which foresees cold forming without following heat treatments. The finished product is fully killed and welding seam bead is inside and outside trimmed. These products are used to manufacture both welded and bolted structures, in the field of constructions, engineering, industrial constructions, transports, automotive, agricultural machinery and earth moving machinery. The cold finished tubes are particularly suitable for structures at sight or for aesthetical uses, thanks to the surface aspect typical of cold forming. NORMS HOT FINISHED” TUBES EN 10210-1/2 COLD FINISHED” TUBES EN 10219-1/2 INSIDE TRIMMING EN 10217

Request for a quote

TAPPI STAMPATI S.R.L.

Italy

D.76 tank cap with key for gasoline, diesel or biodiesel, hydraulic oil and lubricating oil, in technopolymer and steel material, with internal bayonet coupling passage diameter 40 mm and different types of sealing gasket It is available hermetic or ventilated. We can propose this product in a wide range of colors and equipped with safety chains or cables or lock protection door We supply this cap with variable or fixed code key or with the universal fixed code key 455. This product shall be sold with our bayonet filling systems passage 40 mm or with our niches for connection to flexible fuel hose passage Ø 60 mm or with our complete filling systems. The D.76 tank cap with key is used for different applications in several industrial fields, such as generating sets, soundproofed canopy gensets, container, lighting towers, earth moving machines, wheel excavators, auxiliary tanks and so on. Product resulted suitable to approval tests according to the International Standards.

Request for a quote

UNISPECIAL S.R.L. - TURNING CENTER COMPANY

Italy

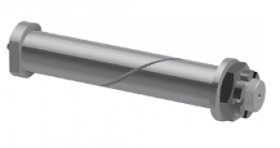

Agricultural and Earth Moving Machinery Precision Parts Machined to Drawing Machining by turning and milling to drawing - from ferrous and non ferrous materials (plastics), from 2 to 40 mm of diameter, very long parts up to 3700 mm. up to 80 mm diameter from bars and up to 300 mm diameter from slugs or castings using multi axis CNC machines Application: components and precition parts foragricultural and earth moving machinery

Request for a quote

UNIL LUBRICANTS

Belgium

For gearboxes of passenger cars, freight lorries, agricultural machines, earth-moving machines and forklift trucks, where API GL4 standard oil is required. It is also suitable for medium-load rear axles and reverse clutches, if they fulfil the ‘extreme pressure’ requirement of the manufacturer. Benefits Increased ‘extreme pressure’ and antiwear properties Excellent lubrication at all temperatures High thermal stability

Request for a quote

URM - UNIVERSAL RUBBER MANUFACTURING NV

Belgium

Cellular rubber is expanded black rubber material with closed cells. Cellular rubber has a lower permanent deformation value than polyethylene foam Available in densities from 90 450 kg/m³. doneAvailable in blocks up to 60 mm thick, depending on the type doneAvailable in rolls with adhesive. More information Cellular rubber are used for static sealing , shock absorbtion, and dampening material in all types of industry earth moving equipment, automotive industry, cab trimming, ventilation, building industry, etc.. Gaskets and flat sealings are produced through die cutting (for high volumes), or by waterjet cutting (for lower volumes and prototyping) Industry use oil and fuel resistance, chemical resistance, temperature resistance, flammability , weather resistance, compression set, compression deflection

BECO GLOBAL UK LTD

United Kingdom

We as experts and logistics providers, we understand that clients may need a helping hand in sourcing products. Motor industry aftermarket services is our speciality. With IT services of assessing also at the centre of daily inspection carried out. We can assist with the sourcing of a wide range of products for ranging from construction materials to apparel, additionally we offer quality inspections and geo-compliance to every destination, customs clearance, insurance and freight. We deal with all demands of product sourcing ranging from: Construction Materials Dangerous and non-dangerous Hazardous and non-hazardous Lights & Lighting Tools Automotive Parts Motor vehicle batteries and lubrication oils. Textiles & Leather Apparel Fashion Accessories Packaging Chemicals Manufacturing & Processing Machinery Food & Beverage Agriculture and other earth moving machinery parts

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

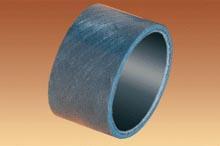

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.tex ® deva.tex ® is a high performance self-lubricating sliding material with a glass fiber reinforced carrying layer. The machinable sliding layer consists of fibers which are embedded in epoxy resin. The resin carries PTFE as lubricant for excellent tribological performance. deva.tex ® bearings are available up to 1.000 mm and are characterized by a very high corrosion and wear resistance. They are insensitive to contamination as well as to vibrations and shock loads. In addition to standard dimension, special geometries can be machined. Max. possible outer diameter 1.000 mm Applications Water turbines, earth moving equipment, hydromechanical engineering equipment, agricultural machines, railroad applications, shut-off valves, chemical industry and many more. Structure 1. Sliding layer: reinforced polyethylene fibers embedded in epoxy resin and PTFE 2. Glass fiber reinforced carrier

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.tex ® deva.tex ® is a high performance self-lubricating sliding material with a glass fiber reinforced carrying layer. The machinable sliding layer consists of fibers which are embedded in epoxy resin. The resin carries PTFE as lubricant for excellent tribological performance. deva.tex ® bearings are available up to 1.000 mm and are characterized by a very high corrosion and wear resistance. They are insensitive to contamination as well as to vibrations and shock loads. In addition to standard dimension, special geometries can be machined. Max. possible outer diameter 1.000 mm Applications Water turbines, earth moving equipment, hydromechanical engineering equipment, agricultural machines, railroad applications, shut-off valves, chemical industry and many more. Structure 1. Sliding layer: reinforced polyethylene fibers embedded in epoxy resin and PTFE 2. Glass fiber reinforced carrier

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.tex ® deva.tex ® is a high performance self-lubricating sliding material with a glass fiber reinforced carrying layer. The machinable sliding layer consists of fibers which are embedded in epoxy resin. The resin carries PTFE as lubricant for excellent tribological performance. deva.tex ® bearings are available up to 1.000 mm and are characterized by a very high corrosion and wear resistance. They are insensitive to contamination as well as to vibrations and shock loads. In addition to standard dimension, special geometries can be machined. Max. possible outer diameter 1.000 mm Applications Water turbines, earth moving equipment, hydromechanical engineering equipment, agricultural machines, railroad applications, shut-off valves, chemical industry and many more. Structure 1. Sliding layer: reinforced polyethylene fibers embedded in epoxy resin and PTFE 2. Glass fiber reinforced carrier

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

The slewing bearing, also known as slew(ing) ring, is a type of bearing for low-speed and high axial load applications. The slewing bearing is a mechanical component that is used in major industrial sectors. Harbor and deck cranes are one of the ideal applications for using slewing bearings – for example, for container handling. Additionally, for wind turbine blades, the use of slewing bearings ensures the highest level of reliability and efficiency, as required by this sector. APPLICATIONS: Earth Moving Machinery Concrete pumps Civil and Harbor Cranes Wind Turbines Radar Robotics Packaging Logistics Material handling Bottling / filling carousels Rotating tables Polyurethane Injection Systems Drilling Rigs Welding Plants Water Treatment Plants Lunapark Woodworking Machines Marble Cutting Machines Palletizers Aerial Platforms Roller Conveyors / Idle Rollers

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

The unique construction of spherical roller bearings make them vital for heavy applications. Their performance is consistent even in extreme conditions, as in the case of high-stress environments and / or reduced lubrication. Spherical roller bearings can give a use life equal to twice that of traditional bearings, according to some estimates. Features of spherical roller bearings: ideal for reduced and medium speeds self-aligning and very robust able to bear radial and axial loads in both directions longer use life compared to traditional bearings excellent compensation for misalignments APPLICATIONS: Earth Moving Machinery Agricultural Machinery Fitness machines Steel working machines Marble processing machines Iron and Steel Industry Oil Industry Automatic opening systems Heavy machinery (eg machines for construction and mining) Bottling / filling carousels Steel mills Industrial transmissions Vibrating equipment / machines Vibrating sieves / vibrating screens

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

A J MARSHALL (SPECIAL STEELS) LTD

United Kingdom

Stocked steel grades: RAEX 400, RAEX 500, BRINAR 400, AR400, 20MnCr6-5. RAEX 400360-440HB3mm - 100mm+ RAEX 500450-540HB6mm - 50mm RAEX STEELS RAEX is a hot rolled hardened steel grade with excellent hardness and strength properties and is resistant to abrasion and extreme surface pressure. RAEX 400 extends the lifespan of machinery, decreases the impacts of wear in structural components and saves costs. Thanks to its high strength properties, RAEX allows innovative and environmentally sound product development. RAEX is easy to weld, cut and has reasonably good formability. TYPICAL APPLICATIONS: Buckets and cutting edges of earth-moving machines, wearing parts of mining machines, wearing parts of concrete mixing plants and wood processing machines, platform structures, feeders and funnels. All steel is supplied with full mill test certificates to DIN EN 10204-3.1. Payment: L/C, T/T, Cheque, Transfer, Cash, VISA.

A J MARSHALL (SPECIAL STEELS) LTD

United Kingdom

Stocked steel grades: 12/14% Manganese, X120 Mn12, X120 Mn13, Creusabro M, ASTM A128 Grade B2, DIN W1.3401. A high manganese, fully austenitic, quench annealed, non-magnetic, work hardening steel with an exceptionally high level of wear resistance when subjected to work hardening by shock or high impact pressure in service. The underlayers not work-hardened maintain an excellent resistance to shock and a very high ductility. TYPICAL APPLICATIONS: Earth moving crusher jaw, grizzly, screen, stone chutes, chain guide, shredder plates, shovel buckets, bucket blade of loader, chain conveyor parts, sprocket wheel, various armouring elements. Guiding and shifting plates, scraps container, liner of shot blasting unit, wear liner, shot blasting equipment. All steel is supplied with full mill test certificates to DIN EN 10204-3.1. Payment: L/C, T/T, Cheque, Transfer, Cash, VISA.

Results for

Earth moving - Import exportNumber of results

20 ProductsCountries

Company type