- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flour milling - machinery and equipment

Results for

Flour milling - machinery and equipment - Import export

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The SMA is a mechanical airclassifier, autonomous equipment designed to separate a material of intermediate fineness (0 to 5 mm for instance) or a ground product (0 to 1 mm or less) into two fractions of different finenesses one fine fraction (particles from 0 to 40 microns up to 500 microns); one coarse fraction (from 40 microns to 5 mm for instance). This air classifier can be used either as a classifier operating in an open circuit (for extraction of natural raw material like sand for instance) or in a closed milling circuit, to control the fineness of ground product or to "preclassify" when the classifier is placed after the air separator and grinding oversize only.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

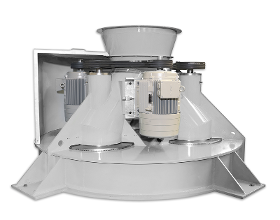

The SHR is the latest generation of our High Efficiency Dynamic Classifier. Our new SHR is used to classify a large range of particles (d98 from 5 to 1000 microns) at a high level of efficiency. This Classifier which is fed by gravity discharge is particularly suited to high throughput rates up to several hundred tons per hour. The SHR is fitted with our patented air seal SEALMAX which allows a very sharp top cut even for very high fineness. The SHR is able to reach high fineness up to D98 5 microns depending on the product. It has been designed to be coupled with every type of mill. In order to improve the yield of this type of separator, POITTEMILL has designed an original system of air purge that extends the time the product remains in the selection zone. With this solution, the recycling becomes external and the recycling of the installation is now meazurable and visible. We can optimize all the classification process

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The DYNAIR is a Double Whizzer Dynamic classifier. This type of separator is usually installed on Pendulum Roller mills but can be used in a pneumatic circuit, alone or combined with a Pulverizer or Ball mill with the possibility of recycling the oversized particles

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

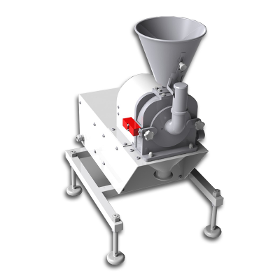

The MICRODYN is an abbreviation of the words "MICROclassificateur DYNamique". It is composed of one or several variable speed classification rotors, clean air for rinsing and a waste discharge spout. It is particularly effective for the production of very fine powder from a pulverulent produced by an existing grinding process. It is fitted as standard on the PAS Integrated Classifier mills. The fine particles are transported by the pneumatic circuit towards a finished product collector (cyclone or filter for finer products). The oversized particles are evacuated out of the circuit along a skirt or through a rotary valve.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

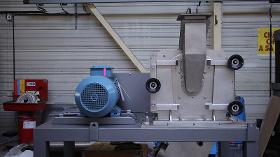

The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range. The main body is made of machined 316L stainless steel single block, it is intended for the small installations of grinding in laboratory. FNG0000 was designed to be able to be settled on a table. The motor and transmission of the crusher are totally enclosed. Smaller, more compact, it possesses nevertheless the same characteristics as a crusher Forplex Nouvelle Génération variable speed, easy plate change, etc.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The Universal FNG mill is an impact grinder that has the key advantage of being fully adaptable. It can be equipped with different grinding tools (hammer plate, pin plate or blade plates) which are adjustable in relation to the product to be ground. The particle size obtained is adjustable via a wide range of sieving screens with varying perforation sizes. Cleaning and maintenance of the FNG is easy. The Universal mill is equipped with air insufflation at bearing level to eliminate all risk of crosscontamination in the case of multiproduct use. The extensive FNG range starts with the FNG 00 laboratory mill (see Labline range) and the FNG1 leading up to the FNG7 for important production capacities.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

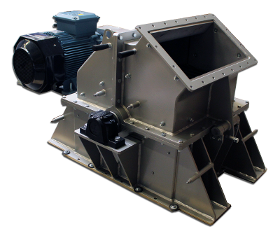

The MA (or Hammer mill) is an impact grinder that crushes the input material between the hammer (or knife) plate and a stator fitted with a sieving screen perforated for the required particle size. It is generally used as a pregrinder positioned upstream of a grinding installation. The MA breaks up blocks of raw material into smaller particles capable of being treated by a mill for fine grinding.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The HammerKnife Universal Mill is the combination between a Hammer Mill and an Universal Mill. As the FORPLEX FNG Mill it can be equipped with different grinding tools (hammer plate ou blade plate) which are adjustable in relation to the product to be ground. The FK Mill has the same advantages as the Universal Pin Mill FNG easy to use, easy to clean, easy to maintain, but also simplicity of changing the grinding tools or grids. Perfect for technical applications such as the grinding of natural ingredients (knife rotor designed for the crushing of plants), the FK mill was designed to meet the standards of the foodstuffs industry, fine chemicals industry, pharmaceuticals industry, nuclear industry or even for cosmetics. It can meet FDA, GMP or ANIA standards and criteria. With the robustness and strength of hammer crusher

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The ATTRIMILL is an attrition mill (or kinetic mill) principally used for plastics or fibrous products. It combines three physical principles that generate efficient ultrafine grinding. The autocomminution of the particles generated by the upward air spiral, The comminution of the particles created by pressure changes generated by variations in the air flux /matter projections against the blades and the stator, The shearing of the particles between the blades and stator grooves. The internal design of the mill depends upon the type of product and the required fineness. The range is divided into several versions according to the sector of activity and products to be treated Stainless steel for foodstuffs, pharmaceuticals or chemicals, ceramic lining for abrasive products, resistance to an accidental explosion (PSR 10 bars) etc... We have a full range from the ATM8 (several kg/h) up to the ATM600 (up to 25t/h).

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

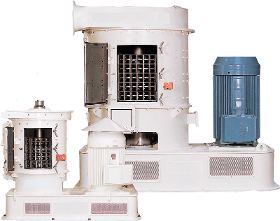

The PAS integrated classifier mill is designed to treat a wide variety of products obtaining a particle size of 99% down to 10µm. The PAS is equipped with a grinding plate and integrated classifier that are driven independently by frequency variation motors. Different versions of the PAS are available, giving a wide flexibility in terms of installation and usage. The variety of grinding tools (plates, liners) when associated with a variable speed static and dynamic classifier guarantees a high quality ultrafine finished product for all applications. The PAS can be equipped with our latest patented technologies SEALMAX© new generation classifier, OPTICYCLE© internal ultrafine recycling system.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The Cylinder mill, commonly known as the Roller Press works by crushing the material between two cylinders kept under pressure by a hydraulic system (2 to 10 T/linear cm). This mill uses a patented process of pulsating pressure that reduces the level of vibration and contributes in reducing energy requirements and prolonging the service life of wearing parts. It is able to treat high production capacities (up to 500 T/h) and produce fine particle sizes (10 to 1000 microns). Cylinder mills allow for energy savings of up to 30% compared with mills that use traditional crushing methods. The cylinders are equipped with an antiabrasive coating which combined with their slow processing speed provide the grinding solution with the longest service life on the market.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The HighYield Pulverizer PHR is a mill that combines the actions of attrition, impact and shearing. It can be equipped with different rotors that accentuate the effects of attrition or impact. The design integrates easy access for maintenance and the replacement of wearing parts. The mechanical parts are situated outside of the grinding chamber to protect them from damage from high temperature drying. Different manufacturing materials are available for the wearing parts as well as ceramic materials for abrasive products that need to avoid contamination by metallic particles. The PHR provides grinding / drying operations for a feeding product of up to 85% humidity. When associated with a Dynamic classifier, very fine particle sizes can be obtained.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material bed. The pendulums mounted on a star wheel are driven by a vertical shaft. Each pendulum is fitted with a grinding roller that rotates upon its axis. The rotation of the star wheel combines with the articulation of the pendulum to generate a centrifugal force at the grinding roller level. The product is ground between the grinding roller and the fixed bull ring.

Request for a quoteResults for

Flour milling - machinery and equipment - Import exportNumber of results

15 ProductsCountries

Company type