- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mills

Results for

Mills - Import export

STEEC

France

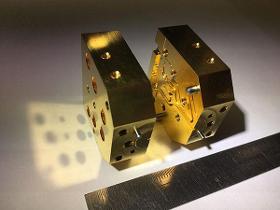

STEEC is able to carry out milling and micro-milling operations on complex mechanical parts with increasingly finer dimensions and increasingly tighter tolerances. STEEC carries out micro-drilling operations to manufacture not only parts but also very high precision electrodes. That enable all spark erosion micro-drilling and countersinking operations to be performed. Equipped with a stock of high-tech machines and leading edge IT tools, such as the Solidworks software, STEEC is capable of meeting special requirements and providing innovative solutions for each of its customers. The experience gained in other high precision machining technologies has enabled STEEC to develop innovative milling processes that are well recognized in the industrial environment.

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing : CNC control :HEIDENHAIN iTNC 530 Number of simultaneous axes : 5 Stroke X axis : 600 [mm] Stroke Y axis : 450 [mm] Stroke Z axis : 450 [mm] Table length : 325 [mm] Table width : 325 [mm] Max. load on table : 200 [Kg] Table surface Ø : 450 [mm] Spindle type : HSK-A 63 Min. spindle speed : 100 [rpm] Max. spindle speed : 20000 [rpm] Spindle power : 13.5 [kW] Tool changer magazin number of stations : 120 Max. tool lenght : 250 [mm] Max. weight of single tool : 6 [Kg] Max. tool diameter : 125 [mm] Supply voltage : 400 [V] Machine weight : 7700 [Kg] ATC weight : 800 [Kg] Automatic Pallet Changer weight : 1200 [Kg] Machine visible under power in our premises by appointment. Price on request, loading on truck included. Possibility of shipping Worldwide.

Request for a quote

DOREY

France

Extraction of individual cards from two removable loading magazines The timing belt transporting system moves the cards from one workstation to another in a synchronizes manner Card thicjness measuring station ensuring only one card is fed CNC cavity high speed milling head for up to 60,000 RPM and dust extraction Hot melt tape spoller, puncher, laminating and peel off system to laminate with chip module tape Chip module punching station and pick & places system for chip module implanting in the cavities Bonding on chip into the card cavity Cooling press qtation Data input device Sorting of cards into good and reject magazines PC based control for easy operation Production capacity of up to 3,000 cards per hour Smooth, low impact operation reduces the noise level of hot melt adhesive Modular design Integrated hot melt lamination system Very stable ans consistent production process

Request for a quote

STEEC

France

At its 4 CN machining centres STEEC drills and taps holes of very small dimensions down to diameters of a few tenths of microns. STEEC carries out micro-drilling work on conventional machining centres. STEEC is able to machine parts in small and medium series or units parts that may have several tens of thousands of holes per parts. The company has acquired know-how and expertise recognized by multiple audits by major contractors in this technology. These audits have also led to special prestigious certifications. This technical solution may be applied in all industrial sectors, from aerospace to the medical sector, also including research or the automotive industry.

Request for a quote

NORELEM FRANCE

France

Milled toothing, straight teeth engagement angle 20°, bright. Outside diameter extruded, tolerance h9. Note The gear rack teeth are cut using a hob mill. This results in minus tolerances for dimensions H and H1 up to module 2 0.2 mm. module 2.5 to 3 0.3 mm.

Request for a quote

NORELEM FRANCE

France

Milled toothing, straight teeth. Engagement angle 20°, bright. Note The gear racks are suitable for mounting in series.

Request for a quote

NORELEM FRANCE

France

Milled toothing, straight teeth. Engagement angle 20°, bright. Note Up to 48 teeth with hub one side, from 50 teeth supplied as disc form. The spur gears have a centre bore or pilot hole (this can vary due to manufacturing methods). For this reason, the dimension D2 max. given in the table is the maximum diameter of the bore with which the spur gears are supplied. This pilot/centre bore can be amended by the customer to produce a reamed bore, reamed bore with keyway or a tapped hole. Alternatively, customers can also use bushes to reduce the bore diameter. Form A with hub Form B without hub

Request for a quote

WEMADE

France

A ream of paper is a standardized package of 500 or 1,000 sheets of paper, typically used for printing, copying, or handwriting. Paper reams are generally made from pine or birch wood and are available in a variety of sizes, types, and paper qualities, such as plain paper, premium paper, recycled paper, laser printer paper, and inkjet printer paper. Some paper reams are also made from eco-friendly materials such as bamboo, cotton, or wood pulp paper

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing : 2018 CNC control : HEIDENHAIN iTNC 640 Number of simultaneous axes : 5 Stroke X axis : 2000 [mm] Stroke Y axis : 600 [mm] Stroke Z axis : 550 [mm] Feed rate on X, Y and Z axes : 20000 [mm/min] Traversing feeds X, Y and Z axes : 40000 [mm/min] Axes acceleration : 2.5 [mm/sec²] Min. distance spindle nose / table : 30 [mm] Table length : 1250 [mm] Table width : 800 [mm] Max. load on table : 500 [Kg] Rotary tilting table surface : 600 x 600 [mm] Stroke C axis : table revolution : 360 [°] Max. speed C axis : 25 [rpm] B axis swivelling stroke : -110 / +110 [°] Spindle type : ISO 40 Max. spindle speed : 15000 [rpm] Spindle power : 17 [kW] Tool changer magazin number of stations : 80 Max. tool length : 300 [mm] Max. weight of single tool : 7 [Kg] Total max. weight in tool changer magazin : 400 [Kg] Total power required : 57 [kVA] Supply voltage : 400 [V] Number of hours under power : 17840 [h] Weight : 15000 Kg

Request for a quote

GRAVOTECH

France

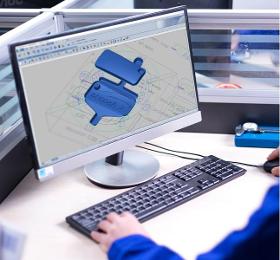

For over 30 years, TYPE EDIT has been the complete CAD/CAM software solution. Taking your ideas and drawings, through design and machining to production. - WITH 400+ POWERFUL FEATURES within 3 interactive modules, TYPE EDIT is packed with vector creation and manipulation tools, combined with 3D bas-relief, connected to a powerful CAM engine creating the smartest toolpath strategies. - COMPATIBLE WITH Unicode, 64 bit, and available in 20+ languages. TYPE EDIT is used across many sectors and applications. - APPLICABLE Engrave, Mark, Cut, Carve in 2D, 2.5D, and 3D within hard metals or soft materials, on any CNC milling machine.

Request for a quote

LBI

France

We manufacture rough or fully machined screw down nuts for rollings mills in high tensile brass, bronze or aluminium bronze

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

Design and manufacture of milling tools such as : - SJM : Super Junk Mill - Junk Mill - Pilote Mill - WOS : WashOver Shoe

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

DRILLSTAR Taper mill is used to repair collapsed casings or tubings, and to shave off cement or corroded parts in casings. The taper mill hardfacing is designed to clean the casing without cutting it, and to penetrate very gradually. The upper part of the taper mill is long enough to allow the addition of stabilizing blades while still remaining easy to fish. DRILLSTAR Taper mill is available in two types, long or short. Blades, whether spiralled or straight, are fully customizable.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

Section mills are designed for cutting and milling a complete section of casing. All models 4 1/2 in. OD and above are equipped with 2 sets of 3 knives: 1 long set and 1 short set, designed for first cutting and then milling the casing. Knives can be hardfaced with your choice of TOPLOY carbide grains or TOPMILL/SWORDFISH tungsten carbide inserts. For most jobs, TOPMILL inserts are strongly recommended to improve milling performance. This tool can be equipped with Flo-tel, which produces a sudden drop in mud pressure when the pipe is cut out, indicating the right time to start applying milling weight.

Request for a quote

LBI

France

We manufacture rough or fully machined segment liners for grinding mills in 15% leaded bronze

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quotePOUGET

France

USE : Holes to countersink the Heads of Coachscrews into Long Wooden Sleepers. ADVANTAGES : Simples, Tough, Adjustable and easy to Re-sharpen. - Steel Body - Superior High-Speed steel blade locked with a conical Key - Range of Adjustment : Ø 38 to Ø 80 mm Hole. - Centering Attachment Ø 15 mm - Total Length = 230 mm - Net Weight = 1 Kg - 23 mm Square Shank Drive - Ref. FR-23 - Ø 16 mm Cylindrical Shank Drive - Ref. FR-16 OPTIONS : - H.S.S Spare Blade ( can be re-sharpened) - Ref. LFR

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

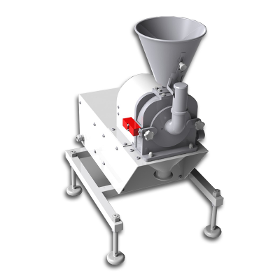

The SMA is a mechanical airclassifier, autonomous equipment designed to separate a material of intermediate fineness (0 to 5 mm for instance) or a ground product (0 to 1 mm or less) into two fractions of different finenesses one fine fraction (particles from 0 to 40 microns up to 500 microns); one coarse fraction (from 40 microns to 5 mm for instance). This air classifier can be used either as a classifier operating in an open circuit (for extraction of natural raw material like sand for instance) or in a closed milling circuit, to control the fineness of ground product or to "preclassify" when the classifier is placed after the air separator and grinding oversize only.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

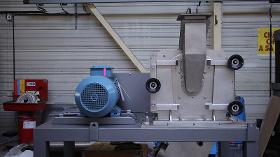

The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range. The main body is made of machined 316L stainless steel single block, it is intended for the small installations of grinding in laboratory. FNG0000 was designed to be able to be settled on a table. The motor and transmission of the crusher are totally enclosed. Smaller, more compact, it possesses nevertheless the same characteristics as a crusher Forplex Nouvelle Génération variable speed, easy plate change, etc.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

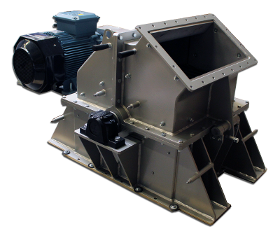

The MA (or Hammer mill) is an impact grinder that crushes the input material between the hammer (or knife) plate and a stator fitted with a sieving screen perforated for the required particle size. It is generally used as a pregrinder positioned upstream of a grinding installation. The MA breaks up blocks of raw material into smaller particles capable of being treated by a mill for fine grinding.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The HammerKnife Universal Mill is the combination between a Hammer Mill and an Universal Mill. As the FORPLEX FNG Mill it can be equipped with different grinding tools (hammer plate ou blade plate) which are adjustable in relation to the product to be ground. The FK Mill has the same advantages as the Universal Pin Mill FNG easy to use, easy to clean, easy to maintain, but also simplicity of changing the grinding tools or grids. Perfect for technical applications such as the grinding of natural ingredients (knife rotor designed for the crushing of plants), the FK mill was designed to meet the standards of the foodstuffs industry, fine chemicals industry, pharmaceuticals industry, nuclear industry or even for cosmetics. It can meet FDA, GMP or ANIA standards and criteria. With the robustness and strength of hammer crusher

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The ATTRIMILL is an attrition mill (or kinetic mill) principally used for plastics or fibrous products. It combines three physical principles that generate efficient ultrafine grinding. The autocomminution of the particles generated by the upward air spiral, The comminution of the particles created by pressure changes generated by variations in the air flux /matter projections against the blades and the stator, The shearing of the particles between the blades and stator grooves. The internal design of the mill depends upon the type of product and the required fineness. The range is divided into several versions according to the sector of activity and products to be treated Stainless steel for foodstuffs, pharmaceuticals or chemicals, ceramic lining for abrasive products, resistance to an accidental explosion (PSR 10 bars) etc... We have a full range from the ATM8 (several kg/h) up to the ATM600 (up to 25t/h).

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

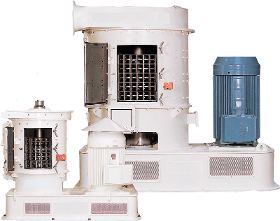

The PAS integrated classifier mill is designed to treat a wide variety of products obtaining a particle size of 99% down to 10µm. The PAS is equipped with a grinding plate and integrated classifier that are driven independently by frequency variation motors. Different versions of the PAS are available, giving a wide flexibility in terms of installation and usage. The variety of grinding tools (plates, liners) when associated with a variable speed static and dynamic classifier guarantees a high quality ultrafine finished product for all applications. The PAS can be equipped with our latest patented technologies SEALMAX© new generation classifier, OPTICYCLE© internal ultrafine recycling system.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The Cylinder mill, commonly known as the Roller Press works by crushing the material between two cylinders kept under pressure by a hydraulic system (2 to 10 T/linear cm). This mill uses a patented process of pulsating pressure that reduces the level of vibration and contributes in reducing energy requirements and prolonging the service life of wearing parts. It is able to treat high production capacities (up to 500 T/h) and produce fine particle sizes (10 to 1000 microns). Cylinder mills allow for energy savings of up to 30% compared with mills that use traditional crushing methods. The cylinders are equipped with an antiabrasive coating which combined with their slow processing speed provide the grinding solution with the longest service life on the market.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material bed. The pendulums mounted on a star wheel are driven by a vertical shaft. Each pendulum is fitted with a grinding roller that rotates upon its axis. The rotation of the star wheel combines with the articulation of the pendulum to generate a centrifugal force at the grinding roller level. The product is ground between the grinding roller and the fixed bull ring.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The BLX mill is an evolution of the F00 the main body is made of a machined 316L stainless steel single block, without any wielding, in order to avoid any product retention inside the mill. It can be installed in different forms according to requirements it may be installed on a mobile platform or in a closed unit with inerted atmosphere or cryogeny. The BLX enables processing of thermosensitive products, or of products that present a risk of explosion or combustion when in contact with oxygen (ATEX Certification).

Request for a quote

INOVER SARL

France

Standard carbide square end mills( 1, 2, 3, 4, 6 dents, HRC45-65) Carbide Ball End Mills(2 Dents) Carbide End Mills for Aluminium Carbide End Mills Long Series

Request for a quoteResults for

Mills - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Flour milling - machinery and equipment (10)

- Milling - machine tools (4)

- Gears (3)

- Milling - steels and metals (2)

- Cutting - machine tools (1)

- Rolling mills - machinery and installations (1)

- Crushing and grinding machinery (1)

- Foundries - copper, bronze and brass (1)

- CAD/CAM Computer Assisted Design/Computer Assisted Manufacturing - software (1)

- Drilling - machine tools (1)