- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cleaning machines- industrial

Results for

Cleaning machines- industrial - Import export

CRYOSNOW GMBH

Germany

• For large surfaces and stubborn contaminations • Powerful round nozzles • Flat nozzles with blasting widths of up to 100 mm (4") • Available as Desktop and Trolley • No power supply, as driven pneumatically

Request for a quote

KLN ULTRASCHALL AG

Germany

With this machine system KLN has created a reasonably priced solution for aqueous part cleaning. Application is possible in all ranges of industry and for all kinds of contamination. The components can be compiled for any process in a modular construction system. They can be supplemented by all systems for tank care as well by an automation of the cleaning processes. The complete PWA series is available also in special sizes. The PWA cleaning tanks are available for determination of residual contamination.

Request for a quote

KLN ULTRASCHALL AG

Germany

“Powersonic” is a type of KLN transducer systems with a particularly good cleaning effect and especially solid design. Transducer plates are ultrasonic transducers that can be flanged. The actual PZT transducer elements are fastened at the back of the sound-emitting transducer plate surface. Plates of different sizes and capacity can be used variably with various operating frequencies of 20, 25, 30, 40 or 132 kHz.

Request for a quote

KLN ULTRASCHALL AG

Germany

Solvent cleaning machines / non-flammable solvent Compact • Standard with Automation • Freely programmable • Ultrasound and Agitation • Vapor Rinse • Freebord drying • Non-flammable Solvents • Meets YOUR BUDGET with Premium Features

Request for a quote

KLN ULTRASCHALL AG

Germany

“Powersonic” is a type of KLN transducer systems with a particularly good cleaning effect and especially solid design. Thus we give full guarantee for up to 12.000 hours in max. 3 years. Submersible transducers are ultrasonic transducer systems in hermetically welded metal housing, inside of which piezoceramic transducer elements are incorporated. They are arranged at the bottom or at the sides of cleaning tanks. The HF current supply is realized via a power supply line which is lead via connection box at the back, a pipe elbow or a flexible metal mesh hose. Various sizes of submersible transducers make possible to use them in operating frequencies differing from 20, 25, 30, 40 up to 132 kHz.

Request for a quote

PERO AG

Germany

The less space between the parts, the more difficult it is to remove particles and contaminants with a wet medium. The handling of the parts and the design of the parts carriers are therefore important aspects for optimised cleaning. Wet media are used in units with 1, 2, 3 or even more baths where the parts are cleaned and rinsed, and, if required, treated with preservation agents.

Request for a quote

PERO AG

Germany

In industrial parts cleaning, wet media are used in 70 to 90 % of all cleaning processes. Wet media include aqueous solutions – similar to detergents we use to wash our dishes or laundry – as well as nonaqueous solvents. For each cleaning task, project engineers must choose the best wet medium, taking into account ecological and economic considerations. Workpieces and parts are produced in finetuned production processes that often require the use of special consumables and process chemicals. Parts are generally made from specific materials, and their contamination after machining is determined by the processes they have undergone. When assessing the environmental impact of cleaning media, one sometimes comes to surprising conclusions. First of all, the energy input and use of resources must be assessed.

Request for a quote

KLN ULTRASCHALL AG

Germany

KLN manufactures various cleaning machines acc. to ATEX (ATmosphère EXplosibles) for the use of combustible liquids. The cleaning machines can be used separately or in combination with other methods. The cleaning tanks must be operated at a well ventilated place. The combustible cleaning agent can be filled in directly into the tanks. The ultrasonic generators are set up separately. A safety thermostat (setting 15°C below the flash point) controls the adherence to a max. temperature and in case of excess temperature it switches the machine off. The cover included in the delivery avoids emissions from the tank during standstills. The machines can also be used in connection with aqueous cleaning methods. Options: • heating • extraction • cooling tube • ultrasonic frequencies 30 and/or 40 kHz • automation system • product carrier

Request for a quote

PERO AG

Germany

By documenting the required technical cleanliness and the processes of your chosen method, you obtain an unrivalled level of process safety at an early stage. You know that you will achieve the necessary technical cleanliness long before you integrate the cleaning unit into your production plant.

Request for a quote

PERO AG

Germany

Bring your dirty parts to the PERO Centre of Competence. The cleaning experts of PERO will advise you in how these parts can best be cleaned. You can then perform a series of tests in order to identify the optimised cleaning process for your parts. Cleaning tests free of charge, using your own parts; including documentation Evaluation of cleanliness analyses Gaining new insights into own cleaning processes

Request for a quote

PERO AG

Germany

PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. In manufacturing plants, parts cleaning is one of the key activities along the production line. The productivity of a manufacturing plant is determined by the availability of the cleaning technology. At the PERO Centre of Competence, PERO specialists work together with operators to develop the cleaning method that best suits their needs.

Request for a quote

PERO AG

Germany

To develop a cleaning solution that meets the specifications, PERO engineers identify the best wet cleaning method and devise the sequence of the process steps as well as the process parameters. The effectiveness and efficiency of the chosen process is then verified by test runs performed at the PERO Centre of Competence.

Request for a quote

PERO AG

Germany

To achieve the required technical cleanliness, the parts must be correctly handled and placed in the cleaning unit. This is normally done by using special parts carriers that can withstand the cleaning conditions.

Request for a quote

PERO AG

Germany

After cleaning, parts are normally dried. Efficient drying keeps cleaning medium consumption low, and thus helps protect the environment. In addition, drying effectively prevents recontamination and corrosion. When drying tightly packed or porous parts, drying at atmospheric pressure might not be effective, so that drying under vacuum is the only option.

Request for a quote

PERO AG

Germany

Hot solvent vapour is applied to the surfaces of the parts where it condensates, forming a solvent film in which dirt is dissolved. As the solvent condensate runs down along the parts, it takes with it the dirt particles (dust, chips, etc.), leaving behind clean surfaces. This physical cleaning effect results in thoroughly cleaned surfaces.

Request for a quote

PERO AG

Germany

Sound waves generated by an oscillator agitate the wet medium. This leads to cavitation bubbles that implode at a high frequency and result in hydraulic impacts. These impacts combined with microflows flush particles and pigments off the parts. The costs of ultrasonic cleaning are primarily determined by the processing time. Low ultrasonic frequencies remove coarse dirt, while high ultrasonic frequencies are used to eliminate fine dirt from parts.

Request for a quote

PERO AG

Germany

The parts are immersed in the wet medium. Dirt is dissolved from the surface by the heated wet medium. By moving the parts while immersed, cleaning is assisted by a mechanical effect. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PERO AG

Germany

The wet medium is sprayed through nozzles onto the surfaces of the parts. Particles are removed from the parts by kinetic energy, and then washed away. The cleaning result is primarily determined by the position and shape of the nozzles, the spray pressure and the volume of media applied to the parts. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quote

PERO AG

Germany

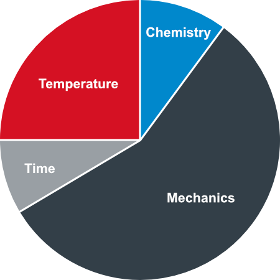

The cleaning process must be designed to eliminate specific contaminants and particles from machined workpieces and parts in order to achieve the required technical cleanliness. For the wet cleaning of parts, the four parameters of the Sinner's Circle need to be combined and adjusted for optimised efficiency. PERO units offer efficient cleaning mechanics and reliable process control. According to the Sinner's Circle, the cleaning result is determined by four basic variables. By adjusting and combining these interrelated variables, it is possible to optimise any cleaning process. Good mechanical design of a cleaning unit optimises the mechanics of the process, which generally means that cleaning is completed in less time and with less resources.

Request for a quote

PERO AG

Germany

Cleaning of machined parts (after turning, milling, drilling, etc.). Particularly suitable for the removal of graphite, AW and EP additives, salts, soaps, and emulsion residue. Generally suitable for the removal of dust, metal chips, surfactants, stearates and polishing paste. Preparation of parts for downstream processing such as joining (by clinching, etc.), assembly and packaging. Cleaning of machined parts (after turning, milling, drilling, etc.). Particularly suitable for the removal of grease, oil, wax, resins, corrosion protection agents and esters. Generally suitable for the removal of dust, metal chips, surfactants, stearates and polishing paste. Preparation of parts for downstream processing such as joining (by clinching, etc.), assembly and packaging. Cleaning of machined parts after turning, milling or drilling, grinding, polishing, lapping and honing, punching and forming (stamping & bending, deep drawing, extruding, etc.).

Request for a quote

PERO AG

Germany

For all cleaning methods, operators must comply with the applicable statutory regulations at local, national and international level. The handling and the treatment of the cleaning media are two important aspects that must be taken into account when assessing cleaning tasks and suitable methods.

Request for a quote

PERO AG

Germany

Wet media differ greatly as regards safe handling, service life and cost of treatment. Surface tension Degreasing properties Cleaning properties Drying properties Residues Filtration properties Bag filter Cartridge filter Distillation Screen basket filter Settling chamber Micro/Ultrafiltration Filling Stabilising Distilling ReFilling Stock bath Bath treatment/Titration Bath change Disposal

Request for a quote

PERO AG

Germany

Acidic, neutral or alkaline wet media Aqueous media remove dirt particles from surfaces and rinse them off. Aqueous detergents disperse particles, and form or separate emulsions. They act on the surfaces of parts. If required, aqueous media can be used to alter the surface properties of parts by passivation (phosphatising), pickling, etc. In all applications, the treatment of the medium itself is of crucial importance. Aqueous media are powerful detergents. Solvents are wet media that are able to dissolve substances without actually reacting with them. The most commonly used cleaning solvents are hydrocarbons and modified alcohols with a flash point > 55°C, and halogenated hydrocarbons. Solvents remove dirt particles from surfaces and rinse them off. Advantages Short cycle times, energyefficient drying, low solvent consumption, long medium service life and easy treatment.

Request for a quote

PERO AG

Germany

The compact KDA tunnel units cater for high throughput rates combined with excellent cleaning and drying. They have been designed for the treatment of parts of many different geometries and sizes. The KDA is available with belts of various widths (200/500/650 mm) and a range of features and accessories to cater for many different cleaning tasks. The KDA is available as 1, 2 and 3bath unit. Cleaning with aqueous media (acidic, neutral or alkaline) Spray cleaning unit for wide range of parts High throughput rate Compact, durable design Available as 1, 2 and 3bath unit with loading of the unit via Robot loading Manualm loading Construction side conveyor technology

Request for a quote

PERO AG

Germany

The ROBOMAT models are designed for the cleaning of a wide range of parts and cater for various levels of cleanliness. Operators can place workpieces and parts of various size and geometry in the processing chamber of the sturdy unit where they are spraycleaned to a high cleanliness level. The model with two baths is particularly suitable for surface cleaning prior to painting and final assembly. Suitable for cleaning, phosphatising and rinsing.

Request for a quote

PERO AG

Germany

The TWT combines a number of cleaning methods in a single unit. Through immersion any spray cleaning with alkaline, neutral or slightly acidic aqueous media, it caters for a wide range of parts and meets even the most stringent requirements regarding technical cleanliness. The cleaned parts are dried under vacuum for extra fast processing. All machine components that come into contact with media are made in stainless steel, allowing for the use of fresh and demineralised water.

Request for a quote

PERO AG

Germany

The modular, preassembled PERO NEPTUN units are available at short notice for your specific application The NEPTUN is a universal machine for the cleaning of a wide range of parts. It guarantees maximum technical cleanliness, irrespective of the degree of contamination of the parts. The NEPTUNfeatures two baths and has been designed for reliable intermediate and final spray cleaning with aqueous media. Its touch panel control enables to devise and run customised cleaning programmes. Cleaning with aqueous media (acidic, neutral or alkaline) 660 x 480 x 300 mm 4 x 480 x 320 x 200 mm Powerful spray cleaning Universal machine Suitable for any cleanliness level from light dirt removal to high technical cleanliness Available as 2bath unit with loading of the unit via Manual loading table Manual charging unit Automatic charging unit

Request for a quote

PERO AG

Germany

The ROTIMAT 3U is a universal machine for the cleaning of a wide range of parts. It guarantees maximum technical cleanliness, irrespective of the degree of contamination of the parts. It is equipped with two baths for cleaning, and subsequent iron phosphatising/rinsing, wherby each bath has its own pump cycle. The ROTIMAT 3U can be operated with standard baskets or customised parts carriers. Cleaning with aqueous media (acidic, neutral or alkaline) 660 x 480 x 300 mm 4 x 480 x 320 x 200 mm Spray cleaning for extra demanding applications Catering for wide range of parts Suitable for any cleanliness level from light dirt removal to high technical cleanliness Available as 2bath unit with loading of the unit via Manual loading table Manual charging unit Automatic charging unit

Request for a quote

PERO AG

Germany

The ROTIMAT 1A has been designed for the spray cleaning of all workpieces that can be placed in the sturdy rotating basket. After production or repair, the workpieces and parts are cleaned with a hot aqueous cleaning medium that is sprayed onto the parts from all sides. The unit can be loaded from the front, or from the top, using lifting gear. The compact machine is equipped with four castors for easy relocation within the factory. Cleaning with aqueous media (acidic, neutral or alkaline) Universell cleaning unit for many different workpieces Compact portable unit with castors Drying without external heat input, or with optional extractor fan Available as 1bath unit with loading of the unit via Manual loading

Request for a quoteResults for

Cleaning machines- industrial - Import exportNumber of results

53 ProductsCountries

Company type