- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electronics development

Results for

Electronics development - Import export

WERNER LANGER GMBH & CO. KG

Germany

The “casing” sector for the electro and electronics industry was developed as a result of demand from the lighting industry for transformer housing for NV lights. Here we can emphasise our housings for electronic mounting devices. Individual customer requirements can be realized cost-efficiently by using insert adapters. Other products for the electrical industry are connectors, strain relief and cable fastening.

Request for a quote

INGENERIC GMBH

Germany

INGENERIC OPTICAL SYSTEMS – CUSTOM-FIT! INGENERIC develops and manufactures optical systems and modules, especially designed and optimized for specific customer requirements. A team of experts in the fields of optical, mechanical and electronical design will not only develop the perfect optical design for highest performance. The module will simultaneously be optimized with regard to all other customer specific requirements. Whether this may be a specifically small housing, a maximum permitted weight or specific demands regarding the cooling area – the required specification will be defined in accordance with the demands of the application and then be put into practice. Last but not least, all of our systems benefit from the utilization of INGENERIC’s high quality micro optics, which are well-known all over the world.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

The DC-voltage converters developed for the electronic components in the motor car are characterised by their ease of installation in every vehicle. The high degree of stability, the compact design, sustained short-circuit resistance as well as the high level of operating safety are the quality hallmarks of this series. The areas of application span the mobile employment of 12-V-consumers in vehicles with a 24-V-onboard network. The devices are particularly suitable for operating car radios, stereo units, radios, cooler units, car telephones, computers, 12-V-trailer lighting etc. The voltage converter converts an input direct voltage into an output direct voltage. The input voltage must be greater than the output voltage. No base load is required at the output end. A 26 kHz PWM switching controller is used for this purpose. Input and output are not isolated. The common earth is connected with the voltage converter housing.

Request for a quote

MERECS ENGINEERING GMBH

Germany

We plan, build and deliver turnkey test systems for electronic and mechanical components. For example, these are test benches for quality assurance, validation and production departments of companies in various industries. Our services include e.g.: - Development test benches - Life time test benches - End-of-line test benches (production) - Retrofit of existing systems (software / hardware) - Climate & temperature test systems - Leakage test benches - Software development LabVIEW, TestStand, Python, C/C++ (Embedded), Microsoft PowerBI, SQL - Electronics development - Mechanical 3D CAD design - Risk assessment and CE - Commissioning, service, maintenance at home and abroad

Request for a quote

MERECS ENGINEERING GMBH

Germany

Merecs develops individual test systems for heat pumps, gas, fluid and water systems. Our engineers & fitters for electronics, installation technology and mechanics build the systems completely from one source at our location in Steinfurt. The systems are then delivered and commissioned at home and abroad. Our range of products includes - Development test benches - Life time test benches - End-of-line test benches (production) - Retrofit of existing systems (software / hardware) - Climate & temperature test systems - Leakage test benches - Software development LabVIEW, TestStand, Python, C/C++ (Embedded), Microsoft PowerBI, SQL - Electronics development - Mechanical 3D CAD design

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BDSENSORS GMBH

Germany

DMP 320 stands for speed and precision. With a response time of ≤ 0.5 msec and a sampling rate of 10 kHz, the pressure transmitter was designed for applications, in which an extremely fast and exact pressure measuring is required. Pressure curves, peaks and hits can be monitored and evaluated exactly. The signal processing of the sensor signal is done by newly developed digital electronics, which detect the signal with a sampling rate of 10 kHz. Sensor-specific deviations such as non-linearity, hysteresis and temperature errors are compensated actively. Features: — nominal pressure: 0 ... 100 mbar up to 0 ... 600 bar — accuracy: 0.1 % FSO — internal sample rate 10 kHz — excellent thermal behavior — excellent long term stability — extremely short response times ≤ 0.5 ms Optional Features: — customer specific versions

Request for a quote

SCHMITZ U. SÖHNE GMBH & CO. KG

Germany

Comfort and reliability in surgery: A multilevel security system ensures uninterrupted surgical proceedings Future-proof software and electronics thanks to in-house-developed electronic parts and software Electrohydraulic leg section and leg support adjustment function, also serving as back section adjustment function in Reverse Mode, allows a precise patient position and intraoperative corrections of position. Generous height adjustment range with multilevel telescopic lifting column by SCHMITZ - for optimal access to the surgical field in both standing and sitting surgery High stability against traction and compression forces allows challenging positions using the extension device Mobility: 4 easy-running ball-bearing castors diam. 125 mm and 5th directional castor, separately activatable Excellent ground clearance: optimal foot access to the surgery table for surgeon and surgical team Quickly adapts to all surgical interventions thanks to versatile and specialised accessories

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Finding out the unrealized potential through the use of weight per unit area gauges One of the most vital factors in the production of wood panels is the constant spreading of material. If tolerances are exceeded, higher material and energy consumption are the consequences. MSX, which constantly moves back and forth across the mat before it enters the hot press, maintains tolerances within the optimum range. The result is homogeneous forming in lengthwise and crosswise directions. The enormous technical developments of “Weight per Unit Area Gauges” of the past years are physically not visible. What are the previous limitations of weight per unit area gauges? The x-ray tube needed a cooling device. This resulted in a reduced lifetime. Electronic Wood Systems developed a detector with extremely high sensitivity – probably unmatched in the world. Due to this new detector the net power could be reduced to a small portion of the permitted power.

Request for a quote

RAFI ELTEC GMBH

Germany

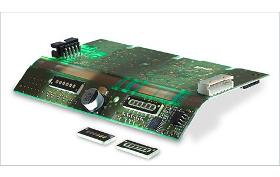

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. At RAFI Eltec, we test the quality of our products across all manufacturing processes. By performing individual tests and integrating fully automatic tests in combined assembly and testing lines, we achieve targeted and effective test cost reductions. For this purpose, we insist on the most cutting-edge technologies and high-quality equipment. Testing technologies - Pull test for chip-on-board - Automatic optical inspection - Flying probe - In-circuit test - Boundary scan test - Function test - Burn-in test and run-in test - Temperature shock test - Temperature humidity test You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Providing maximum quality for your ideas and products is what motivates us. To achieve this, we introduce our high quality standards to projects even before manufacturing begins. As a result of our expert analysis of customer data, potential pitfalls are eliminated in advance. We document sample productions in detailed test reports and discuss them with you. Due to our state-of-the-art testing technology and our in-house test equipment construction, we increase the quality of your production while simultaneously reducing logistics costs. You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions and achieve our mutual goal: your satisfaction and success.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Even if the production process uses NoClean fluxing agents, special requirements sometimes call for a special cleaning process: with our state-of-the-art ultrasonic cleaning system, we reduce ionic residual contamination to a minimum. As a result, the cleaned assemblies can be quickly and safely further processed. Our focuses: - Assembly cleaning - Checking for assembly cleanliness You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions and achieve our mutual goal: your satisfaction and success.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Whether with a mini-wave or a Wörthmann wave, we deliver customary RAFI Eltec quality on our automatic soldering equipment even for wired assemblies. We apply various technologies here – coordinated to each individual project. Our focuses: - Wired assembly - Wave soldering (ROHS-compliant or leaded) - Automated selective soldering - Lift-dip soldering (multi-wave) - Manual soldering - Assembly - Visual inspection You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions and achieve our mutual goal: your satisfaction and success.

Request for a quote

RAFI ELTEC GMBH

Germany

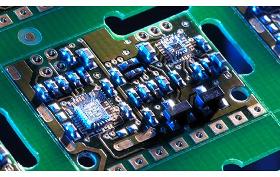

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. RAFI Eltec operates 5 fully automatic SMD high-speed, precision assembly lines with nitrogen reflow soldering technology. Our focus: - BGA, µBGA, CSP - QFN, Finepitch - 0201 - Novel components - Package-on-package - Automatic optical inspection Providing maximum quality for your ideas and products is what motivates us. To achieve this, we introduce our high quality standards to projects even before manufacturing begins. As a result of our expert analysis of customer data, potential pitfalls are eliminated in advance. We document sample productions in detailed test reports and discuss them with you. Due to our state-of-the-art testing technology and our in-house test equipment construction, we increase the quality of your production while simultaneously reducing logistics costs.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Efficient production processes and reliable execution of the overall implementation are characteristic for RAFI Eltec. As a result of our many years of experience in energy measurement technology and in radio and network applications, we have accumulated unique production and testing expertise. This is also naturally to your advantage in regard to the final assembly of your devices. Final assembly - Assembly presses and screw fittings - Ultrasonic welding - Adhesive robots - Semi-automatic and fully automatic assembly - Automated testing - Laser or inkjet printing technologies - Leak tests - Box build You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process.

Request for a quoteResults for

Electronics development - Import exportNumber of results

15 ProductsCountries

Company type

Category

- Electrical & Electronic Components (6)

- Measurement and regulation equipment and instruments - pressure (2)

- Electric transformers, converters and rectifiers (1)

- Measurement and regulation equipment and instruments - electricity and other energy (1)

- Medicine and surgery - apparatus and equipment (1)

- Optical measuring equipment (1)

- Testing equipment (1)

- Wood veneer - machinery and equipment (1)