- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cleaning-%20industrial

Results for

Cleaning-%20industrial - Import export

PERO AG

Germany

The wet medium is sprayed through nozzles onto the surfaces of the parts. Particles are removed from the parts by kinetic energy, and then washed away. The cleaning result is primarily determined by the position and shape of the nozzles, the spray pressure and the volume of media applied to the parts. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

The mobile solution for machinery health monitoring The VIBXPERT II from PRUFTECHNIK is the mobile power package for fast and reliable recording and analysis of machine condition data. After a very short measuring time, the current machine status data is shown on the color display. The maintenance expert can analyze the data on site. From the recorded machine condition data, all values can be read from the various characteristic value modes that are important for an exact machine condition analysis. The device is used directly on site at the machine, from the machine hall to the diesel generator of an oil tanker or from a bucket excavator to a hydroelectric turbine. The robust design enables both fast and complex interventions. Whether in clinically clean systems, or harsh industrial environments. VIBXPERT II sets the standard in mobile machine and plant condition monitoring.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

High absorbent properties of a natural fiber with the cleanliness, strength, and durability of synthetic wipers; woodpulp added to polyester foundation long fibers providing excellent absorbency minimal extractable and ionic contaminants low static wipe meets the requirements for ISO Class 7 and FEDSTD209/D Class 10,000

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

made of 100% Nonwoven PP material, with continuous filament 80 g/m² economic low lint wipe high water absorbency rate, lowlint and soft texture good water and oil absorbency suitable for cleaning of e.g. PCB solder paste, tools, machines, etc.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

made of microthin fibers with highest degree of cleanliness superior moisture and oil absorbency The unique construction of fibers absorbs up to 50% more compared to ordinary polyester wipers. nonabrasive complys with ISO requirements of Class 4 and FEDSTD209/D Class 10

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

100% polyester (75D / 72F) can be used under class 1.000 up to class 10.000 wipe is washable, with negligible deterioration in its performance Soft and nonabrasive on surfaces; good absorbency rate low particulates and ionic contents

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

100% polyester; double knitted to provide efficient cleaning of surfaces during maintenance of cleanroom under class 1000 to class 100,000. good absorbency rate multipurpose reusable wipe; washable wide range of application for cleaning specially cleanroom equipment like computers, electronic equipment, laboratory apparatus, tables and chairs, etc.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

knitted with carbon fiber recommended for ESDsensitive applications and cleanroom environment where particles is a concern complys with the ISO requirements of Class 4 and FEDSTD209/D Class 10

Request for a quote

COMPUR MONITORS GMBH & CO. KG

Germany

Carbon dioxide detection in industrial plants: Measuring range 0 – 5 % or 0 – 2 % vol. For Martians – provided they exist – a carbon dioxide atmosphere might be their natural habitat. We earthlings can only tolerate low concentrations of this gas. It is true that we are using the special properties of CO 2 for many purposes, but in concentrations above 5000 ppm it can be hazardous to our health. Therefore it must be monitored. In areas that are rarely accessed, such as beverage dispensing facilities, a leak detector might do as a warning device. Wherever people are present, such as workplaces in plants, industrial grade gas detection equipment is required. Here it is: Statox 501 IR. This new version of the field proven Statox 501 IR for combustible gases operates as a 4 – 20 mA transmitter. It can be connected directly to a recording device, process control system, or the optional Statox 501 controller. Its unmatched compact design makes it operable in any environment whether it is food industry, chemical industry, refineries, or cleaning facilities. This explosion proof instrument will do the job everywhere. It is water proof (rated IP 67). The housing materials (stainless steel and fiber-reenforced polyamide) are rugged and easy to clean.

Request for a quote

PERO AG

Germany

The less space between the parts, the more difficult it is to remove particles and contaminants with a wet medium. The handling of the parts and the design of the parts carriers are therefore important aspects for optimised cleaning. Wet media are used in units with 1, 2, 3 or even more baths where the parts are cleaned and rinsed, and, if required, treated with preservation agents.

Request for a quote

PERO AG

Germany

The ROTIMAT 1A has been designed for the spray cleaning of all workpieces that can be placed in the sturdy rotating basket. After production or repair, the workpieces and parts are cleaned with a hot aqueous cleaning medium that is sprayed onto the parts from all sides. The unit can be loaded from the front, or from the top, using lifting gear. The compact machine is equipped with four castors for easy relocation within the factory. Cleaning with aqueous media (acidic, neutral or alkaline) Universell cleaning unit for many different workpieces Compact portable unit with castors Drying without external heat input, or with optional extractor fan Available as 1bath unit with loading of the unit via Manual loading

Request for a quote

PERO AG

Germany

The ROTIMAT 3U is a universal machine for the cleaning of a wide range of parts. It guarantees maximum technical cleanliness, irrespective of the degree of contamination of the parts. It is equipped with two baths for cleaning, and subsequent iron phosphatising/rinsing, wherby each bath has its own pump cycle. The ROTIMAT 3U can be operated with standard baskets or customised parts carriers. Cleaning with aqueous media (acidic, neutral or alkaline) 660 x 480 x 300 mm 4 x 480 x 320 x 200 mm Spray cleaning for extra demanding applications Catering for wide range of parts Suitable for any cleanliness level from light dirt removal to high technical cleanliness Available as 2bath unit with loading of the unit via Manual loading table Manual charging unit Automatic charging unit

Request for a quote

PERO AG

Germany

The TWT combines a number of cleaning methods in a single unit. Through immersion any spray cleaning with alkaline, neutral or slightly acidic aqueous media, it caters for a wide range of parts and meets even the most stringent requirements regarding technical cleanliness. The cleaned parts are dried under vacuum for extra fast processing. All machine components that come into contact with media are made in stainless steel, allowing for the use of fresh and demineralised water.

Request for a quote

PERO AG

Germany

In industrial parts cleaning, wet media are used in 70 to 90 % of all cleaning processes. Wet media include aqueous solutions – similar to detergents we use to wash our dishes or laundry – as well as nonaqueous solvents. For each cleaning task, project engineers must choose the best wet medium, taking into account ecological and economic considerations. Workpieces and parts are produced in finetuned production processes that often require the use of special consumables and process chemicals. Parts are generally made from specific materials, and their contamination after machining is determined by the processes they have undergone. When assessing the environmental impact of cleaning media, one sometimes comes to surprising conclusions. First of all, the energy input and use of resources must be assessed.

Request for a quote

PERO AG

Germany

Wet media differ greatly as regards safe handling, service life and cost of treatment. Surface tension Degreasing properties Cleaning properties Drying properties Residues Filtration properties Bag filter Cartridge filter Distillation Screen basket filter Settling chamber Micro/Ultrafiltration Filling Stabilising Distilling ReFilling Stock bath Bath treatment/Titration Bath change Disposal

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PERO AG

Germany

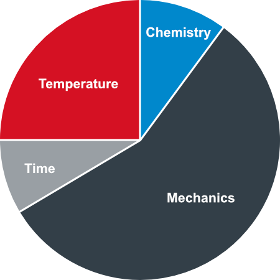

The cleaning process must be designed to eliminate specific contaminants and particles from machined workpieces and parts in order to achieve the required technical cleanliness. For the wet cleaning of parts, the four parameters of the Sinner's Circle need to be combined and adjusted for optimised efficiency. PERO units offer efficient cleaning mechanics and reliable process control. According to the Sinner's Circle, the cleaning result is determined by four basic variables. By adjusting and combining these interrelated variables, it is possible to optimise any cleaning process. Good mechanical design of a cleaning unit optimises the mechanics of the process, which generally means that cleaning is completed in less time and with less resources.

Request for a quote

PERO AG

Germany

To develop a cleaning solution that meets the specifications, PERO engineers identify the best wet cleaning method and devise the sequence of the process steps as well as the process parameters. The effectiveness and efficiency of the chosen process is then verified by test runs performed at the PERO Centre of Competence.

Request for a quote

PERO AG

Germany

The compact KDA tunnel units cater for high throughput rates combined with excellent cleaning and drying. They have been designed for the treatment of parts of many different geometries and sizes. The KDA is available with belts of various widths (200/500/650 mm) and a range of features and accessories to cater for many different cleaning tasks. The KDA is available as 1, 2 and 3bath unit. Cleaning with aqueous media (acidic, neutral or alkaline) Spray cleaning unit for wide range of parts High throughput rate Compact, durable design Available as 1, 2 and 3bath unit with loading of the unit via Robot loading Manualm loading Construction side conveyor technology

Request for a quote

PERO AG

Germany

The modular, preassembled PERO R2 units are available at short notice for your specific application Thanks to its unique design and optimised process technology, the R2 offers maximum throughput rates and excellent cleaning quality. At the same time, the unit is know for its energy efficiency. The performance of the R2 is primary determined by the size of the parts carrier and the cycle time per batch. As the R2 is available with chambers of various size, it is probably the most flexible cleaning unit in its class Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit 660 x 480 x 300 mm (std.) 1.000 x 480 x 300 (B chamber) 1.340 x 480 x 300 mm (D chamber) High flexibility Maximum throughput Unrivalled cleaning quality Available as 1 and 2bath unit with loading of the unit via Manual charging unit Automatic charging unit Hall trolley

Request for a quote

PERO AG

Germany

The modular, preassembled PERO S1 units are available at short notice for your specific application The compact S1 degreases and cleans components made from various materials and of many different geometries and degrees of machining. The S1 is designed for dirt and grease removal at low energy and resource consumption. It therfore is the ideal entrylevel unit for cleaning with solvents in a closed system. The integrated distilling unit ensures process safety and efficient cleaning at a consistently high level. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; other solvents on request 530 x 320 x 200 mm or 530 x 365 x 250 mm Entrylevel mpdel for cleaning with solvent in closed system Configurable for short cycle times Vapour degreasing in 1st process step Available as 1bath unit with loading of the unit via Manual charging unit Automatic charging unit

Request for a quote

PERO AG

Germany

The modular, preassembled PERO N2 units are available at short notice for your specific application Thanks to its highly efficient process technology and low energy consumption, the N2 offers excellent cleaning results and high throughput. Operators can choos from a range of solvents in order to achieve best cleaning results for their specific tasks. The energy manager function enables operators to control the heating output for maximum energy efficiency. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Standardised and strong High efficiency High throughput combined with ourstanding cleaning quality Available as 1 and 2bath unit with loading of the unit via Manual charging unit Automatic charging unit Hall trolley

Request for a quote

PERO AG

Germany

The R5 units from PERO are able to clean large quantities as well as large workpieces in a highly efficient manner with short cycle times. Thanks to its large-capacity processing chamber, the R5 is particularly popular with companies in the automotive and aerospace industries, as well as those of forming plants, heat treatment specialists and contract cleaners where high cleaning capacity is a must. Suitably dimensioned tanks guarantee excellent degreasing and cleaning results in single-shift and multiple-shift operation, even at high throughput rates. Cleaning Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Highlights - High flexibility - Maximum throughput - Unrivalled cleaning quality Availability Available as 1- and 2-bath unit with loading of the unit via - Hall trolley - Pallet truck - Automatic charging unit

Request for a quote

PERO AG

Germany

Acidic, neutral or alkaline wet media Aqueous media remove dirt particles from surfaces and rinse them off. Aqueous detergents disperse particles, and form or separate emulsions. They act on the surfaces of parts. If required, aqueous media can be used to alter the surface properties of parts by passivation (phosphatising), pickling, etc. In all applications, the treatment of the medium itself is of crucial importance. Aqueous media are powerful detergents. Solvents are wet media that are able to dissolve substances without actually reacting with them. The most commonly used cleaning solvents are hydrocarbons and modified alcohols with a flash point > 55°C, and halogenated hydrocarbons. Solvents remove dirt particles from surfaces and rinse them off. Advantages Short cycle times, energyefficient drying, low solvent consumption, long medium service life and easy treatment.

Request for a quote

PERO AG

Germany

Hot solvent vapour is applied to the surfaces of the parts where it condensates, forming a solvent film in which dirt is dissolved. As the solvent condensate runs down along the parts, it takes with it the dirt particles (dust, chips, etc.), leaving behind clean surfaces. This physical cleaning effect results in thoroughly cleaned surfaces.

Request for a quote

PERO AG

Germany

Bring your dirty parts to the PERO Centre of Competence. The cleaning experts of PERO will advise you in how these parts can best be cleaned. You can then perform a series of tests in order to identify the optimised cleaning process for your parts. Cleaning tests free of charge, using your own parts; including documentation Evaluation of cleanliness analyses Gaining new insights into own cleaning processes

Request for a quote

PERO AG

Germany

PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. In manufacturing plants, parts cleaning is one of the key activities along the production line. The productivity of a manufacturing plant is determined by the availability of the cleaning technology. At the PERO Centre of Competence, PERO specialists work together with operators to develop the cleaning method that best suits their needs.

Request for a quote

PERO AG

Germany

To achieve the required technical cleanliness, the parts must be correctly handled and placed in the cleaning unit. This is normally done by using special parts carriers that can withstand the cleaning conditions.

Request for a quoteResults for

Cleaning-%20industrial - Import exportNumber of results

47 ProductsCompany type