- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- nozzles - non-ferrous metal

Results for

Nozzles - non-ferrous metal - Import export

KAMAT GMBH & CO. KG

Germany

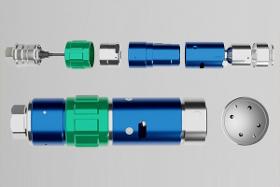

Optimum surface cleaning with KAMAT high-pressure rotating nozzles In order to ensure a surface treatment with excellent results and within a reasonable time, we have developed special externally driven rotating nozzles suitable for our high pressure pumps: Depending on the customer's requirements, our nozzles can be driven pneumatically, electrically or hydraulically. With traditional, self-powered rotating nozzles, the water jet hits an angle before it exits the nozzle, causing the nozzle to rotate. Driving the rotating nozzle causes the water jet to lose energy and is therefore much less efficient. Our externally driven rotary nozzles concentrate the hydraulic energy entirely on the machining process. KAMAT rotating nozzles provide coherent jets that can be moved precisely and quickly over large areas. In the case of externally driven rotation, the hydraulic energy is used entirely on the surface being sprayed, giving excellent and efficient results on surfaces.

Request for a quote

KAMAT GMBH & CO. KG

Germany

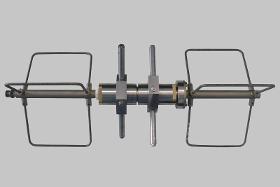

The nozzle consists of two counter-rotating nozzle housings into which the nozzle tubes are inserted with a connection for screw-in round jet nozzles. A special packing sealing system inside the nozzle housings ensures protection during operation and prevents the ingress of contaminants. In front of and behind the nozzle housings are spacers (basket system) to prevent the nozzle tubes from hitting the well wall. In addition, for best cleaning results, the temperature of the medium should be between 3 and 30°C.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

EP Ehrler Prüftechnik manufactures single nozzles in the flow rate range from 0.005 to 2000 m³/h with highest accuracy up to 0.12 % MW. In addition to our standard range, we also manufacture customer-specific nozzles that are perfectly designed for your application in compliance with DIN EN ISO 9300*. Nozzle holders including sensor connections are available for all nozzle sizes for installation in customer applications. Different nozzles can be combined to set different flow rates, allowing a high number of different flow rates to be generated quickly. With 8 critical nozzles, for example, 2^8 = 256 different flow rates can be generated. A binary staggering of the nozzles ensures an even coverage of the volume flow rate range.

Request for a quote

SEIKI DEUTSCHLAND GMBH

Germany

We have minimized the weight of our manifolds without restricting ist vital functions and thus enable high energy savings for our customers. In addition, our manifolds are known for an uniform temperature distribution and no dead spots in the flow channels preventing the resin from deterioration.

Request for a quote

SEIKI DEUTSCHLAND GMBH

Germany

No sprue losses with the perfect cold runner system. Material costs, expenses due to scrap and additional working hours in post-processing can be reduced considerably by using our RUDIZ system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SEIKI DEUTSCHLAND GMBH

Germany

Our hot-halves complete systems mean all-round service for you, we are at your side from construction to the final sampling at your factory and keep you up to date with simulations.

Request for a quote

SEIKI DEUTSCHLAND GMBH

Germany

Seikis valve gate nozzles are available with independent heating of the nozzle tip and the shaft. The can be controlled individually and, therefore, synchronized with the injection for less wear and tear and a clean closure of the nozzle.

Request for a quote

SEIKI DEUTSCHLAND GMBH

Germany

Our patented Spear nozzles with thermal-sealing via the separate tip-heater open up new possibilities in injection molding, especially when processing glass fiber or carbon fiber reinforced resins.

Request for a quoteResults for

Nozzles - non-ferrous metal - Import exportNumber of results

9 ProductsCountries

Company type

Category