- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pharmaceutical industry - machinery and equipment

Results for

Pharmaceutical industry - machinery and equipment - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are made by aluminium, used for the mechanical support and connection, after process then doing sandblasting + natural oxidation.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

After every successful filling of a package, it is a basic condition for precise dosing that the thread is defined and breaks off cleanly. This effect usually occurs with water-like materials - with viscous products, so called semi-solids, but often not: Many products such as creams, gels and ointments pull long threads from the tip of the dispensing needle into the respective packaging. The ViscoTec Pharma Dispensers provide a solution: After a dosing shot of the Pharma Dispenser, the product path through the chambers in the rotor-stator system is blocked, thus preventing dripping of the dosing medium. A valve at the dosing needle or at the pump is not necessary. Thanks to the reversible direction of rotation, retraction can be set after the end of dosing: The material is drawn back into the dosing needle in a defined manner.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

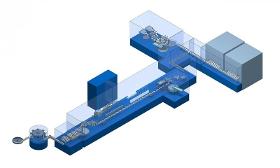

Lödige has years of expertise in continuous granulation. Nowadays, continuous ringlayer mixers are established systems for continuous granulation in many industries. However, until now the Lödige product range was missing a suitable dryer. The continuous fluid bed dryer closes this gap. Together with the ringlayer mixer CoriMix® and the customer-specific dosing system, this dryer provides a complete continuous granulation line: GRANUCON®. Dryer operation is based on the fluid bed process. A general disadvantage of continuous fluid beds is the wide retention time distribution within the machine. Lödige’s developers have looked into this problem and have found a solution: integrating a screw in the fluid bed dryer. This has a limiting effect on the retention time distribution. — Exchangeable floor — Quick screw removal — Integrated WIP cleaning — Individual purging of filter elements

Request for a quote

BUSS-SMS-CANZLER GMBH

Germany

The SMS thin film evaporator type HYVAP serves the increasing demand of the pharmaceutical industry for continuous concentration of heat sensitive, viscous and fouling products. Hygienic design for the pharmaceutical industry The HYVAP is a horizontal thin film evaporator that allows easy access and inspection of the interior and controlled and reliable CIP cleaning. The technology of the HYVAP combines the proven advantages of our conventional horizontal thin film evaporators DKH with the following new features: • Cantilever rotor design • Comfortable rotor extraction • No bearing in product space • Mechanical seal in hygienic design • Electro-polished surfaces • Sight glasses for inspection during operation The new HYVAP DZH offers the hygienic design that meets current GMP requirements. The evaporator sizes range from 0.1 m2 for laboratory to 2.0 m2 for industrial applications. LP steam as well as hot water can be applied as heating media.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory vacuum shovel dryer DRUVATHERM® is a system provides reliable scale-up to production scales in the context of product and process development and can likewise be used for small batch production too. The Lödige laboratory vacuum shovel dryer DRUVATHERM® is a horizontal, batch vacuum dryer with a frequency-controlled mixing tool. This mixer consisting of mixing elements adapted to the process and arranged on a shaft according to a specific system - is installed in a cylindrical mixing drum equipped with a temperature control jacket. Rotation of the mixing unit generates a three-dimensional product movement, in which all of the product is constantly in motion. The contact frequency of particles with the heat exchange surface leads to shorter drying times. The chopper rotating at high speeds fitted to the side of the mixing drum is used to disperse the product . This leads to a significant increase in drying capacity and prevents moisture and temperature gradients.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The granulation dryer is designed for continuous operation. A unique property of this dryer is its combination of convection and contact drying. Adaptation of the retention time to the specific process ensures that products are dried at low temperatures. At the same time, excellent granulation of the final product can be achieved. This intense mixing effect separates the particles in the fluid bed, thereby creating a large product surface and preventing the generation of temperature and moisture gradients in the product bed. This leads to a significant increase in the heat exchange via the heated drum walls. The product behaviour during drying is affected by the mixing tool geometry and choppers can be activated as an option; these can be used to control the average product retention time and the retention time distribution. It is therefore possible to achieve a defined grain size distribution during granulation processes

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The Lödige laboratory tablet coater has a modular design, so that integration of any components is customised according to the customer’s specific requirements. A dividable drum and a dividable nozzle arm allow processing of even very small volumes (0.6 l). The coater and the optionally available liquid supply station consist of Corian®, a highly resistant, light-weight, FDA-approved material, which is crucial for the particularly functional and modern design of the laboratory coater system. The laboratory coater is not just a “laboratory machine”, but a full coating system, in which process conditions comparable to those of Lödige production coaters are generated. The mobile laboratory coater incl. the drum for the tablets and drawer for the nozzle arm and tool form the base unit. In addition, the following equally mobile modules are available: — Air supply unit — Exhaust air unit — Liquid supply station (optional)

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The coaters series type LC were specifically developed for coating tablets. With our coater range, Loedige is one off the technological market leader. The maximised tablet bed surface in the Lödige coater and the maximum number of spray nozzles mean that extremely high liquid volumes can be applied with extremely high air supply volumes within a very short time. The newly designed, particularly low-turbulence air routing ensures a highly efficient and gentle use of dryer air. These features ensure a reliable coating process and short process times. Moreover, the low-turbulence air routing prevents contamination from the very start, thereby reducing the cleaning workload. Modern sensors permit optimisation of the spraying and drying process. Simple yet secure nozzle arm adjustment makes for easier handling.

Request for a quote

OPTIMA LIFE SCIENCE GMBH

Germany

- Modularity: Quick change and addition of modules - Scalability: Machine can be extended from an entry level machine to a fully-automated production line - Intermittent motion: Lab machine - Continuous motion: Pilot plant production - Continuous motion, multiple lanes: Large volume production Applications - Product development - Manufacturing of product samples - Clinical tests - Market launch - Production Perfect for new products and business areas - Covers small and medium production needs

OPTIMA LIFE SCIENCE GMBH

Germany

Technical Data: Output: up to 1,200 products/min (multi lane, single lane solutions available) Web speed: up to 70 m/min Web width: max. 320 mm (special widths on request) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Compensating for height tolerance Simple operation Intermittent operation or continuously working Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available safety devices Gently objective handling Simple operation Continuously working Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available safety devices Gently objective handling Simple operation Compact design Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

1-lane supply All commercially available ready-to-use syringes (glass and plastic) Simple operation First-in-first-out principle Intermittent operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Do you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA PHARMA GMBH

Germany

ATEX model optional Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Simple operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available syringes nested in tubs and bags Aseptic fields of application Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Simple operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) Aseptic fields of application Gently objective handling Disposable product path optional Dosing system: Mass flow with CIP/ SIP optional Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available syringes nested in tubs and bags Aseptic fields of application Processability of three different container types (vials, cartridges and syringes) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Gently objective handling Simple operation Intermittent operation Ultrasound pretreatment optional Small amount of format parts Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Processability of three different container types (vials, cartridges and syringes) Simple operation First-in-first-out principle Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available safety devices Simple operation Appropriate for small batch production and laboratory applications Continuously working Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available safety devices Simple operation Intermittent operation Very good accessibility Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Results for

Pharmaceutical industry - machinery and equipment - Import exportNumber of results

99 ProductsCountries

Company type

Category