- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- robot automation

Results for

Robot automation - Import export

IGUS® GMBH

Germany

The twisterchain product line offers a wide range for circular movements and is available in four sizes. Modular in width and radius, therefore flexible in applications where rotary and spiral movements up to 360° and more with high loads and smooth operation are required. The twisterchain applications are available with guide trough, which has the following advantages: guidance of the energy chain, reduced abrasion of the energy chain, optimal operational smoothness, rotation angle up to 360° from stock. - Strong, high fill weights, smooth operation, weight-optimised - Rotary speeds up to 1m/s and more - Circular/spiral movements up to 360° from stock (up to 400° upon request) - Cable-friendly, smooth interior crossbars openable along the inner and outer radius - Successfully tested for over 1 million cycles in the igus laboratory

Request for a quote

SAMSYS GMBH

Germany

The EasyPalletizer from EasyRobotics is a stationary palletizing robot for loading pallets with cardboard boxes or workpieces. The system is positioned on a conveyor belt. Then the robot picks up the cardboard box or the workpiece with a gripper. Depending on the proramization, it then sets it down on the pallet according to the customer’s requirements. The integrated ER+ software facilitates the programming of the sequence. Structure In combination with the Universal Robots robot UR10e the palletizer is available in different versions: On the one hand, the EasyPalettizer can be equipped with a base with lift. This makes it possible to move a stroke of 265 mm with the robot. Crates and workpieces can be stacked even higher on the pallet. Furthermore, it is possible to install a fixed base. This limits the standard height of the robot to 855 mm. In addition, the base can also be completely dismantled. This is useful if the palletisation will not reach great heights.

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

With a fixed storage tray, the ProFeeder Light palletizing robot from EasyRobotics is ideally suited for automated processes of small series. A cost-effective application that sets new standards in precision machining when combined with a robot from Universal Robots. Equipped with special software and the help of UR+ Caps, set-up times as well as machining times can be greatly reduced. In addition, employees can concentrate more on more important activities and increase productivity.

Request for a quote

SAMSYS GMBH

Germany

The handling robot ProFeeder Table from EasyRobotics is a perfect assistant for processes in the field of grinding, polishing and deburring. A cost-effective application that sets new standards in precision machining when combined with a robot from Universal Robots. Equipped with special software and the help of UR+ Caps, set-up times as well as processing times can be greatly reduced. In addition, employees can concentrate more on more important activities and increase productivity.

Request for a quote

SAMSYS GMBH

Germany

The pick-and-place robot ProFeeder from EasyRobotics consists of a basic module and two carriages, which guarantee a big range of workpiece pick-up options. A cost-effective application that sets new standards in precision machining when combined with a robot from Universal Robots. Equipped with special software and the help of UR+ Caps, set-up times as well as processing times can be greatly reduced. In addition, employees can concentrate more on more important activities and increase productivity.

Request for a quote

SAMSYS GMBH

Germany

The ProFeeder Compact from EasyRobotics is a robust robotic cell with compact dimensions that can be easily moved in your production. The ProFeeder Compact is placed separately in front of the machine to be operated. Then an ER Work or an ER Pedestal is positioned in front of the machine. The robot is located on the ER Work / ER Pedestal. The robot now takes workpieces from the ProFeeder Compact and loads and unloads the machine. It then loads the workpieces back into the ProFeeder Compact. This results in advantages for you, such as more space in your production, quick adaptability for different workpieces and a mobile robot cell. Thanks to the simple design of the drawers of the ProFeeder Compact, workpieces of various sizes and lengths can be processed without major changeover work.

Request for a quote

SAMSYS GMBH

Germany

The automatic drawer system ProFeeder X from EasyRobotics with its up to 10 drawers is perfectly suited for productions from small to large series. It shines not only because of its performance thanks to the included software, but also because of its changeover times. The software, which has been specially created for the ProFeeder X, makes it easier to write the robot programs in the palletizing area. This reduces tiresome programming times and increases productivity at the same time.

Request for a quote

SAMSYS GMBH

Germany

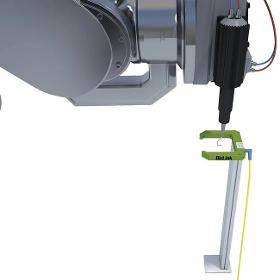

The Quick Changer system enables quick and easy tool change. It has a low weight, a low installation height and is designed for a payload of up to 20 kg. It is patented, reliable and equipped with a user-friendly connection mechanism. Particularly secure locking structure and locking springs. The Quick Changer system is a unique product and ideal for all collaborative robotic applications. The Quick Changer is the easiest and fastest tool changer. Simply everything you need in one package. Not only suitable for OnRobot products. It can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example is the use of existing tools. These can also be equipped with OnRobot’s quick change system. The Quick Changer is alternatively also available as Dual Quick Changer. This makes it easy to install two tools on one robot arm.

Request for a quote

SAMSYS GMBH

Germany

The OnRobot force-torque sensor provides accurate force and torque measurement along all 6 axes. This gives you precise control during difficult assembly, polishing, grinding or deburring. In addition, the HEX software offers path recording, force control and special functions for insertion. This reduces the integration time for your production line. Our sensors are suitable for most of the industrial robot arms currently in use. Common applications are polishing, grinding, deburring and assembly. They can also be used for teach-in applications and collision detection. Currently available models: HEX-E – High precision, HEX-H – Low deformation, HEX-E QC, HEX-H QC Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Request for a quote

SAMSYS GMBH

Germany

With the new intelligent OnRobot screwdriver for light industrial, cooperation and assembly robot you can easily automate processes. Intelligent error detection and handling of multiple screw sizes ensures consistent results and drastically reduces your cycle time. Seamless integration with the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc. Functionality Due to the simple connection of the screwdriver and the operation and programming via the own URCap (only applies to Universal Robots) the grippers are ready for use in the shortest time. In addition, the connection time is reduced by the OnRobot quick-change system Quick Changer and Dual Quick Changer.

Request for a quote

SAMSYS GMBH

Germany

With the robot camera Eyes from OnRobot, the provision of image processing for almost all collaborative applications becomes easy and cost-effective. Eyes is suitable for the sorting of a large number of objects. For example for CNC machines with metal parts defined by their outer shape and many other pick-and-place applications where alignment is important. Calibration and part recognition with only one single shot takes only a few minutes. Programming is intuitive and fast. And with Eyes’ advanced, affordable 2.5D vision, you benefit from depth perception and the ability to stack parts without adding complexity. The simple one-system setup for all leading robot manufacturers comes with software that is easy to install and program. Even employees without a technical background can perform the setup. Calibration and part recognition with a single shot. Simply take an image of the work surface to calibrate the camera view. One image for each part you want the system to detect.

Request for a quote

SAMSYS GMBH

Germany

The mobile robot ER Work from EasyRobotics is a compact robot station which can be used for handling work or CNC assembly. The ER Work is most often used in combination with the ProFeeder Compact. Here the ProFeeder Compact serves as a kind of parts store. In this case the ER Work loads and unloads the machine. Of course, the ER Work can also do its work alone in front of a CNC machine.

Request for a quote

SAMSYS GMBH

Germany

Do you want to use the OnRobot grippers as double grippers? The Dual Quick Changer double gripper system allows the use of different OnRobot gripping tools in one pass. With this innovative solution, you can use two RG2 grippers or one RG6 gripper with a VG10 – it’s up to you. Switch quickly and seamlessly between our tools with the Dual Quick Changer to maximize the utilization of your robots. With the Dual Quick Changer, throughput times can be accelerated and thus the productivity of your plant increased. Not only suitable for OnRobot products. The DUAL Quick Changer can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example are existing tools, which can also be equipped with the OnRobot quick-change system. The Dual Quick Changer is the alternative to the Quick Changer. This makes it easy to install two tools on one robot arm.

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FORMHAND AUTOMATION GMBH

Germany

The ability to gently handle components of different dimensions, geometries and surface structures opens up completely new possibilities. The small gripping head offers flexible and simple cooperation between man and machine. Benefit from ✅ Increased efficiency of your processes ✅ Increased availability of your personnel ✅ Increase in the production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R80 ✅ Industrial robot applications for components up to 2 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Bin picking applications ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

ROTEG AG ROBOTER TECHNOLOGIE

Germany

The three axis of motion enable a high performance and an efficient design of the robot system. The central pick up table picks up a whole layer of glass from the pallet. The table pushes the layer on the discharge table in one operation which seperates the glasses and transfers them to the production line. Since the roTeg depalletizing robot DERO II works with clamping jaws, numerous package sizes can be processed without mechanical devices. In each depalletizing cycle the interlayers are also picked up by the glass layer and collected in a magazine. The movability of the robot construction on the x axis enables the handling of different production lines. While one discharge table is still filled with glasses and being emtied line by line the DERO II already takes the next layer and serves the second discharge table.

Request for a quote

ROTEG AG ROBOTER TECHNOLOGIE

Germany

The palletizing robot system PARO® has a modular structure. This is how the palletizing room can be optimally adapted to the palletizing task – even afterwards. The spectrum ranges from standard single place cells which are not bigger than the pallet itself, to palletizing systems with twelve or more palletizing stations. All of this is easily determined by a correspondingly long horizontal axis. The palletizing robot PARO® is a four-axis robot whose axis have a special guide system: Profiled, teflon coated Vulkollanrollers run on polished stainless steel tubes. This system has proven itself to be robust and maintenance free. With this simple system technology a lot of industrial handling processes are economically automated in different performance areas. The PARO® is durable and also suitable for the use in extreme enviroments. All in all the robot offers a good price-performance ratio.

Request for a quote

BIZLINK ROBOTIC SOLUTIONS GERMANY GMBH

Germany

The advintec TCP tool calibration system calibrates the tool or fixture electronically in up to six dimensions. The robot program is automatically corrected by the measured variations and ensures that the tool always operates at the correct position. advintec TCP is a high-precision calibration system that can be used for all robot types and most robotic tools, making it independent of specific manufacturers. Correction takes place directly and automatically in the ongoing production process.

POREX TECHNOLOGIES GMBH

Germany

Maximum consistency in airflow, filter purity, and aerosol containment POREX® Automation Certified Pipette Tip Filters are customized and optimized to meet the fit, air flow, and volume placement of your specific robotic and automated liquid-handling instruments, sample processors and dispensing systems. To streamline laboratory operations and production, these automation and robotic pipette tip filters are backed by the Certified Pure Porex™ Program and: Maximize air flow –Delivers optimal dispensing and pipetting performance across a wide range of liquid volumes. Prevent cross-contamination–Eliminates aerosol bypass and sample carryover. Increase sample throughput–Provides tighter tolerance control for increasing laboratory workflow and reducing instrument downtime.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

LOAD CELL AND TORQUE SENSOR – X/Y/Z - Model 8565 In robotics and automation engineering, the requirements for precise, tactile handling are constantly increasing. The robust 8565 multi-axis sensor with its low crosstalk enables you to monitor and evaluate your process at any time, regardless of the sensor’s orientation. With just one sensor, you can obtain accurate three-dimensional load information. Its six independent outputs let you selectively evaluate the direction of action of the loads (axial force [Fz] / lateral forces [Fx/Fy] / torque [Mz] / bending moment [Mx/My]). Thanks to its compact design and adaptation via the standardized robot flange in accordance with DIN ISO 9049-1, the sensor can be integrated into many applications quickly and easily. When the slightest deviations are detected in your fast-moving and complex production processes, you can intervene immediately to make adjustments. This helps to prevent faulty parts and reduce manufacturing costs.

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

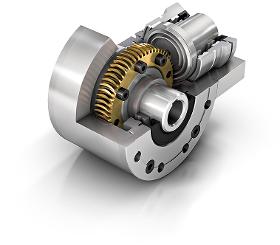

Takeover of the Torus gear technology In September 2016, MS-GRAESSNER GmbH & Co. KG acquired the entire technical expertise of TEDEC AG, Zofingen/Switzerland. Read more ... This results in an ideal synergy effect: state-of-the-art gear meshing technology combined with many years of experience in gear engineering. The further development of the TORUS gearbox (TorusGear), including series development, is thus guaranteed - also from the perspective of customer-specific applications. The owner-managed company MS-GRAESSNER GmbH & Co. KG is a manufacturer of high-precision servo angular gearboxes, with over 60 years of experience in drive technology. The products are used in particular in the fields of automation, robotics, electromotive, and mechanical and plant engineering.

Request for a quote

ELKON GMBH

Germany

ELKON twin shaft mixers, which successfully produce concrete for various projects all around the world, has been manufacturing in ELKON’s technological factories for long time. ELKON is capable of producing 500 twin shaft mixers per shift annually thanks to its fully automated robotic welding lines. Advanced Features of ELKON Twin Shaft Mixers - Longer lifetime with robust mixer body manufactured by fully automatic welding robots - Able to produce of all kinds of concrete (Ready-mixed concrete, precast concrete, roller-compacted concrete-RCC, heavy concrete, etc.) - High homogeneity even in shorter mixing times - Highly wear-resistant, durable wearing parts - Easy maintenance due to wide maintenance gates and bolted type replaceable linings - Heavy duty gearbox (Brevini or Bonfiglioli from Italy) - Automatic lubrication system (Lincoln - Germany) - Universal compatibility to existing concrete plants with compact design

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

From semi-automated to fully automated - from simple to complex: As a manufacturer of special systems, we are specialized in assembly systems to develop according to customer requirements, so that innovative products can be created. We are industry-neutral, i.e. our systems are used in the most diverse industrial sectors. We have references in automotive, medical technology, e-mobility, renewable energies and aerospace. Here you can find a selection of the implemented assembly system types: - Robot solutions - Interlinked systems - Fully automated lines - Rotary transfer machines - Manual workstations - Hybrid systems An in-house development from our company is the VARIOMODUL®, which allows your system to be quickly adapted to dynamic market changes. Standardized modules, processes, handling technology and peripherals are used. For further information please refer to the corresponding download.

Request for a quote

SIKO GMBH

Germany

With flexCoder technology, the MSAC200 can be flexibly adapted to the customer's design and provides precise absolute values with high installation tolerances at the same time. It is basically possible to adapt the encoder and the magnetic ring for precise fitting, for example in motors. An additional feature is the high reading distance ≤0.6 mm and axial tolerance of ±0.2 mm to facilitate the design of the overall system and enable use in dynamic applications. Customer-specific design. Integration into small installation space possible. Absolute resolution up to 21 bit. Repeatability 0.01°. Reading distance ≤0.6 mm. Interface BiSS C, SSI. Optional analog real-time signal output Sin/Cos 1 Vss. Industrial and medical applications e.g., motor feedback, handling automation and robotics.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The capaNCDT DT61x4 is an active, capacitive system for displacement, distance and position measurements. Consisting of a sensor with integrated preamplifier, a robust cable and a compact controller, the measuring system is immediately ready for use without any on-site calibration. The measuring system is available with a cable length up to 15 m and is ideal for automation purposes. The capaNCDT 61x4 is particularly suitable for automated robot manufacturing and measurement tasks with a drag chain. Moreover, it is used in machine building and semiconductor production. For optimum signal quality, the desired cable length is already factory-calibrated.

Request for a quote

TRAPO GMBH

Germany

With decades of know-how and worldwide expertise in the core areas of conveyor technology, robot systems, palletizing, depalletizing and automation, TRAPO AG presents itself as a renowned manufacturer and total systems supplier of conveyor systems, palletizing technology and packaging machines. Primary and secondary packaging such as cartons, trays, pails and more are palletized and depalletized. The machines in our systems impress with their flexibility, high performance and economic efficiency. We produce in Germany and set standards worldwide ranging from engineering contracts to automation. The palletizers of the HLP series operate with high and low inlet. The product range of the high-capacity layer palletizers is optionally equipped with a y-axis, rotary module or even a traversing axis — so that one or more palletizing stations can be operated as required.

Request for a quoteResults for

Robot automation - Import exportNumber of results

45 ProductsCountries

Category

- Robotics (17)

- Industrial robots (13)

- Assembly robots (12)

- Welding robots (4)

- Mechanical engineering - custom work (3)

- Sensors (3)

- Automation - systems and equipment (2)

- Palletising machinery (2)

- Bearings, roller (1)

- Concrete mixers (1)

- Construction - Machines & Equipment (1)

- Cutting, plastics - machinery (1)

- Handling - Machines & Equipment (1)

- Import-export - electrical and electronic equipment (1)

- Machine vision system (1)

- Measurement and control instruments (1)

- Painting robots (1)

- Welding work - steels and metal (1)