- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- engines

Results for

Engines - Import export

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

We offer you a comprehensive service portfolio around your measurement technology: whether we support you in the complete project or only in sub-areas, is entirely up to you. Starting with the project planning and construction, over the commissioning and support with the CE certification up to the maintenance of your test stand - our offer extends.

Request for a quote

JEGO INGENIEURBÜRO GMBH

Germany

Technical problems and new ideas are the inspiration of our engineers while creating the solution for your substation to fulfill the project requirements. The broad expertise in different protection and control vendors and the excellent collaboration with our partners we deliver solutions for your substation. Our expertise in engineering lies within: Parameterization and configuration of IEDs SCADA modeling and integration with protocols IEC 60870-5, DNP3, Modbus etc. SAS/SCS modeling and integration via IEC 61850. SCL-files modeling. You find a detailed view of our expertise on our website:

Request for a quote

WERNER LANGER GMBH & CO. KG

Germany

The “casing” sector for the electro and electronics industry was developed as a result of demand from the lighting industry for transformer housing for NV lights. Here we can emphasise our housings for electronic mounting devices. Individual customer requirements can be realized cost-efficiently by using insert adapters. Other products for the electrical industry are connectors, strain relief and cable fastening.

Request for a quote

VOXELJET AG

Germany

The VX2000 is a 3D printer for industrial applications. It is a particularly good choice for cost-effectively producing large-format models from sand cores for prototyping. The VX2000 can also be used to economically manufacture small-series components. The machine is fast and easy to operate. The build space measures up to 2,000 x 1,000 x 1,000 mm. The VX2000's print head system can achieve a resolution of up to 300 dpi. A layer applied in one cycle is 300 µm thick.

Request for a quote

VOXELJET AG

Germany

The VX4000 is the world's biggest industrial 3D printing system for sand molds. It has a cohesive build space measuring 4,000 x 2,000 x 1,000 mm (LxWxH). This machine can be used to economically produce very large individual molds, a great many small series components or a combination of the two. With its uniquely large volume, the VX4000 maximizes productivity and flexibility. The unique and patented layering process was specially adapted for this printer. Instead of lowering the building platform during the printing process, the print head and coater are raised with each layer. As a result, the machine can bear the enormous weight of the building platform, which can be quickly exchanged via a rail—making it possible to print nearly continuously. Sand can be used as the particulate material. The VX4000's print head system can achieve a resolution of up to 300 dpi. A layer applied in one cycle is 300 µm thick.

Request for a quote

VOXELJET AG

Germany

Our international bestseller: the VX1000 is a universal 3D printer for industrial applications. The machine is fast, easy to operate and enables you to cost-effectively produce medium-sized molds, cores and models for making prototypes. The VX1000 is also suitable for producing small series. Plastic and sand can be used as the particulate material. The piezo print head system of the VX1000 achieves a resolution of up to 600 dpi. The machine's build space measures 1,000 x 600 x 500 mm. The thickness of a layer applied in one cycle is 150 µm for plastic and 300 µm for sand. In addition, the VX1000 concept is environmentally friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quote

VOXELJET AG

Germany

The VX500 is a 3D printer for industrial applications that has been tried and tested many times over in practice. These machines can be found wherever there is a demand for the straightforward production of prototypes and models. Despite their compact dimensions, they captivate with the features of a high-performance printer, such as multi-jet print heads, integrated material handling and job boxes. The machine is very fast, easy to operate and permits cost-effective production of both individual parts and small series alike. Plastic can be used as the particulate material. The machine's build space measures 500 x 400 x 300 mm. The VX500's print head system can achieve a resolution of up to 600 dpi. The thickness of a layer applied in one cycle is 150 µm. In addition, the VX500 concept is resource-friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quote

VOXELJET AG

Germany

The VX200 is the most compact 3D printer in the voxeljet portfolio. It weighs a mere 450 kilograms and, thanks to its dimensions of only 1,700 x 900 x 1,500 mm (LxWxH), the VX200 can be installed without problems in places where space is tight, such as research laboratories. The machine is very fast, easy to operate and permits the economical production of small prototypes and design pieces. Plastic and sand can be used as the particulate materials. The build space measures 300 x 200 x 150 mm. The VX200's print head system can achieve a resolution of up to 300 dpi. The thickness of a layer applied in one cycle is 150 µm for plastic and 300 µm for sand.

Request for a quote

ERTEMES GMBH

Germany

A qualified Electrical Engineering Specialist has a profound education as well as specialized knowledge and qualifications in the field of electrical engineering. He ensures that electrical systems and equipment are properly installed, maintained, and operated. He is also the point of contact for all safety-relevant standards and regulations in electrotechnical matters. ErTeMes will be happy to support you and take on tasks of the qualified Electrical Engineering Specialist in your company, e.g.: Testing and (re)establishing the proper and standard-compliant condition of your electrical machines, systems, and equipment; Troubleshooting when things get stuck; Documentation according to current standards; Training and instruction of your employees; Coordination of work processes.

Request for a quote

ERTEMES GMBH

Germany

Do you need support in the design of electrical circuits or in the preparation of circuit diagrams? ErTeMes GmbH helps with preliminary planning and needs analysis and creates appropriate layouts and circuit diagrams according to your requirements and considering the current standards. We can also take care of further work, such as control cabinet construction, for you. ATEX and SIL safety requirements can also be incorporated into the electrical planning if required. ErTeMes GmbH provides you with a safe, energy-efficient, and professional result.

Request for a quote

OPEN GRID EUROPE GMBH

Germany

Our Gas Quality Competence Centre answers chemical analysis and process engineering questions in all matters connected with the transportation and use of natural gas. Our Competence Centre uses high-performance methods and processes for the analysis of gases and accompanying substances and can draw on many years of experience in the operation of our transmission system and cooperation with customers. The full range of our laboratory services if of course also available to other companies and organisations. They include: Determination of natural gas compositions in accordance with DVGW Code of Practise G 260 Natural gas analyses up to C14 Determination of trace concentrations of accompanying substances Water analyses on preheaters in accordance with DVGW Code of Practise G 495 Natural gas safety data sheet and much more Our Gas Quality Competence Centre is certified to DIN EN ISO 9001. The natural gas analysis laboratory is accredited to DIN EN ISO/IEC 17025.

Request for a quote

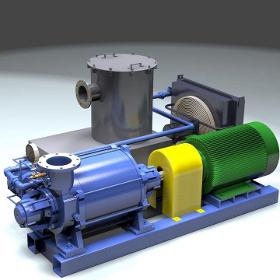

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

The new NASH XT Systems use the Nash pump advantages within a water-saving, self-contained system. Their capacity range is 200-1300 CFM (340-2210 m3/h). Designed for use in clean applications, such as medical centers, labs, paper converting, semiconductor applications, dairy and more, XT Systems give you the benefits of a liquid ring vacuum pump without the problem of providing constant seal liquid.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

The NASH Vectra XL series of liquid ring pumps was designed to operate as both a vacuum pump and a compressor with a maximum pressure differential of 30 psig. This allows a negative pressure to be applied to the wells and can: assist in the production of low pressure natural gas and/or remove low pressure gas to aid in the production of oil. The discharge gas can be sent to a high pressure reciprocating compressor for pipeline transport. The systems are built on a platform that can be moved from well to well as needed.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

150 - 3000 CFM The pre-engineered VectraPaks are a versatile and readily available system for any industrial vacuum need. The Vectrapak comes with the accessories already mounted and piped for ease of installation. They are available from 150 to 3000 ACFM, suitable for operation to 29" HgV, and are available in both iron and stainless steel construction.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

40-150 CFM Pre-engineered SX Packages are a versatile and readily available system for any industrial vacuum need. The SX Packages come as either once-through or recirculated packages with the accessories already mounted and piped for ease of installation. Built with Nash patented gas scavenging, to increase high vacuum performance, they are available from 40 to 150 ACFM (70-250 m3/hr), suitable for operation to 29" HgV (31 mbar abs), and are available in cast iron construction.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

These Duplex Vacuum Systems consist of an air ejector, two Vectra XL350 liquid ring vacuum pumps, interconnecting piping and related instrumentation. The vacuum pumps and ejector are manufactured in Aluminum Bronze and the piping interconnections are manufactured in Fiberglass Reinforced Epoxy. These special materials of construction ensure the usual Nash reliability even in the harsh conditions of offshore production.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Chemical Process Industry / Oil & Gas Industry Our vacuum and compressor systems maximize output and efficiency while minimizing maintenance and environmental pollution. Made of stainless steel and other sophisticated materials, they handle explosive and corrosive gases safely and efficiently. Pulp & Paper Industry Providing vacuum pumps and related equipment to the pulp & paper industry is a Gardner Denver Nash specialty. We are well known as an industry leader in engineered vacuum systems and water removal for paper machines. NASH vacuum pumps are used throughout the forming and press sections of a paper machine. Power Industry For over half a century, NASH has been the manufacturer of choice for air removal systems in steam cycle power generation plants throughout the world. NASH condenser exhauster packages efficiently remove inward air leakage from the condenser and improve the efficiency of the turbine under all operating conditions. Other Industries For more than 100 years, Nash has engineered liquid ring vacuum pumps, liquid ring compressors and engineered systems for the toughest applications. Our systems operate dependably for decades in filter applications, refineries, the sugar industry, in the food processing industry, mining and many more applications.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Steam Ejectors & Liquid Ring Vacuum Pumps Engineered for optimum efficiency, Nash Hybrid Systems now offer a 15% reduction in steam consumption. This was achieved through extensive R&D efforts, resulting in innovative design improvements. Nash has designed and manufactured hybrid systems since 1979, and our hybrid systems are recognized worldwide for reliable performance and low greenhouse gas emissions. As the new standard for Nash hybrid designs, these systems maintain traditional benefits, while offering accelerated payback through increased energy savings, condensers designed per HTRI specifications and a faster response time through regional sourcing. Nash is the only company to manufacture both the pumps and ejectors that go into a hybrid system, and offers a complete system warranty. All Nash hybrid systems are backed by global aftermarket support, decades of engineering expertise, and a proven history of reliable, dependable installations. Existing all ejector systems can be upgraded to more efficient hybrid systems by replacing or modifying stages. Nash engineers can evaluate your specific systems and recommend a custom hybrid design that will optimize your energy savings. Through reduced operating costs, upgraded systems can offer a payback of 2 years or less. Nash hybrid systems are used in industries and applications where deep vacuum is required and system reliability is critical. In operations where efficiency is key, emissions are a concern, or if there is a scarcity of steam in the plant, Nash hybrid systems are the optimal solution for efficiency.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Gardner Denver Nash’s HP and NAB compressors are the ideal choice for recovering fuel gas and condensing valuable hydrocarbons, making more money for the refinery. When reviewing the total life cycle cost of a flare gas compressor system, the NASH liquid ring system provides more value and better reliability than any other technology, hands down. Liquid ring compressors run cool and they clean the gas as they compress it–eliminating the need for downstream aftercondensers and scrubbers. The result is a simpler, more reliable system.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

From the first planning to shipment, every project is accompanied by one constant contact person. Depending on industry, process and specification, the best material (steel, stainless steel, duplex materials, titanium, plastic material) is chosen. There is a big importance to consider and meet the different standards and rules. Whether its DIN, ISO, ATEX, GOST ASME or PED (pressure equipment directive) - Nash engineers know all these general frameworks and restrictions. Our team of engineers finds the best solution to realize the customer's requirements.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

For over half a century, NASH systems have been the products of choice for air removal systems in steam cycle power plants throughout the world. By reducing the energy loss due to air leakage into the condenser, our vacuum systems save millions of dollars worth of energy every day.

Request for a quote

EC AUTOMATIC GROUP-GERMANY GMBH

Germany

Our company provides a full range of services for the development and implementation of automated process control systems for industrial enterprises. We are ready to help with the design, modernization, start-up and maintenance of various production lines or individual units of technological processes. 1423 engineering projects have been completed in close cooperation with the technologists and design teams of our clients. We automate existing production facilities, participate in the development and installation of facilities under construction, supply equipment and carry out commissioning, perform further technical and service maintenance. For today, our team is more than 150 people: engineers, managers, equipment installation and maintenance specialists. Be assured – we will carefully study your tasks and provide the best solutions.

Request for a quote

IUQ INSTITUT FÜR UMWELTSCHUTZ UND QUALITÄTSSICHERUNG DR. KRENGEL GMBH

Germany

Waste & recycling Examination of pollutants & expert support of dismantling of buildings & technical installations Site coordination by experts for safety & health protection when working in the contaminated area according to DGUV Rule 101-004 (formerly BGR 128) Health & safety plans for work in the contaminated area Emission monitoring of landfill sites (groundwater monitoring, leachate investigations, gas emission measurements, soil monitoring) Contaminated sites & claims Collection, exploration & evaluation of old sites, old deposits & claims Renovation management & support Site coordination by experts for safety & health protection when working in the contaminated area according to DGUV Rule 101-004 (formerly BGR 128) Aftercare concepts & examinations (eg groundwater monitoring) Inspection/quality control Inspection of the production & storage of wood pellets Quality assurance concepts & monitoring of secondary fuels and waste wood Supervision of biogas

Request for a quote

TEREX INDIA R&D CENTER - TIRC

Germany

Terex has an Engineering R&D Center in Bangalore, India offering engineering and technical services. Technical office, with 160+ engineering professionals using multiple software packages in CAD, FEA and Electrical/Hydraulics 3D platforms. Our teams, structured on platforms, products and projects, can support Product Development, Technical Publications, Mechanical Design, Engine Emissions Updates, Electrical and Hydraulic Engineering, Software, Design Analysis and Validation, 2D-3D Drawing Creation, Manufacturing Engineering, and more. Our Engineers bring with them experience they have gained on projects with various manufacturers. This is how we offer an enormous amount of knowledge about product creation and product life cycle achieving high engineering productivity and cost-effective resource management, maximizing the return on investment for our customers

Request for a quoteResults for

Engines - Import exportNumber of results

26 ProductsCountries

Company type