- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sheet metal welding

Results for

Sheet metal welding - Import export

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

we process thin sheets, heavy plate, wear-resistant sheet and plate. aluminium sheets, stainless steel sheets, copper sheets, brass sheets and much more, with formates from 3000 to 8000 mm (118" to 315"), with thickness 1 mm – 180 mm (0,039" to 7") welded sheet metal structures, aluminium constructions, industrial profiles

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

RONIX GMBH

Germany

The Ronix RH-1440 sheet metal locking plier is a quality product from the varied collection of Ronix hand tools and sheet metal pliers. This tool is used to hold and move sheet metal, bend the corners of workpieces, curve the edges of parts, and clamp and hold sheet metal to be welded while working. The Ronix RH-1440 8-inch sheet metal clamp is made from high-quality stainless steel. In addition, its wide, machined, standard-size jaws are designed to hold the part in position. The clamping force of this tool is evenly distributed, so the sheet metal is not damaged during transport

Request for a quote

MECHASYS GMBH

Germany

Electrical Steel: rotor and stator sheets as full service Due to the growing demand for electrical steel, we have bundled our technological resources and expanded the production of pure sheet metal blanks to complete packages in stator and rotor sheets. We are therefore able to provide you, our customers the service of complete sheet metal stacks baked, laser-welded or punched packaged in the electrical steel sector. Due to our extremely thin cutting gap of just 0.07mm - as much as the diameter of a human hair - we are able to produce the smallest contours. The extreme power density at a max. laser power of 1,000 watts enable electrical sheets based on baked varnish technology with the lowest possible edge zone melting - burr-free. Everything 100% "Made in Germany" in packaged quality - usually tolerance class T7. Usual delivery times are approx. one week for cutted sheets, 2-3 weeks for baking or welding parts. Let’s get in contact for your new e-drive, rotor or stator!

Request for a quote

EWM AG

Germany

— Degaussing of pipes and metal sheets — Automatic degaussing before welding — Dependable degaussing for better welding results through stable welding process without magnetic deflection, minimisation of finishing work — activgauss (10–250 A) – degaussing during welding: — Avoids moving up of magnetic field during the welding process in case of very long and strongly magnetised components — Portable and robust — Quick connection at the pipe by means of three load cables — Use at -25 °C to +40 °C with mains voltage tolerances of +/- 20% Advantages of degaussing: — No deflection of the arc by residual magnetism in the workpiece — Prevention of lack of fusion due to insufficient sidewall fusion — Minimisation of finishing work — Cost-efficient and high-quality results — Set: Degauss 600 degaussing machine, two 5-metre, 35 mm² load cables, one 20-metre, 35 mm² load cable, RT DGS1 remote control and 5-m connection cable

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

THIELMANN ENERGIETECHNIK GMBH

Germany

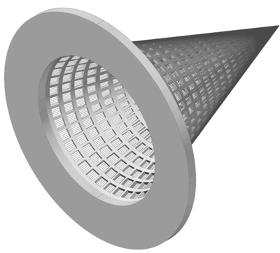

CHARACTERISTICS For clamp mounting into the pipeline Efficient protection of dirt-sensitive system components during commissioning Low differential pressure Easy installation and replacement Material Certificates DIN EN 10204/3.1 for Clamp Collar OPTIONS For DIN and ASME flange connections Design for low temperature down to -50 ° C Design pressure up to 100 bar Stainless steel construction Reverse flow direction GENERAL The starting screen VAS is used for commissioning and starting a system in order to clean gas from coarse soiling such as welding bead, scale, grease, etc. After starting, the starting screen can be removed from the pipeline. The design is carried out as a welding design. FUNCTION The starting screen VAS consists of a supporting basket made of perforated sheet metal with a welded clamping ring. These are galvanized after assembly. On the outside of the support basket a stainless steel wire mesh is welded.

Request for a quote

ASSFALG GMBH

Germany

The automatic bevelling machine CHP 21G is designed for the stationary and portable use in weld seam preparation. A cutting wheel shears off the edge in a low-noise and dust-free way, leaving a rough chamfer. It is extremely robust and suitable for continuous operation. It delivers consistent and high-quality bevels in the sheet metal welding preparation process.

Request for a quote

EPP ENERGY PEAK POWER GMBH

Germany

This flat rate for the proven Alumero substructure for pitched roofs allows you to calculate your offers quickly and easily. Please note that the individual static calculation must be made by us at the latest when you place your order.

Request for a quoteResults for

Sheet metal welding - Import exportNumber of results

9 ProductsCountries

Company type