- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tanks

Results for

Tanks - Import export

BS BODENSTECKDOSEN SYSTEMTECHNIK GMBH

Germany

Round CEE floor tank 7022A with lockable lid made of saltwater-resistant aluminum. The CEE floor tank is installed at floor level and can be driven on by car due to its solid construction. Waterproof when closed. Protection class IP 67. Standard surface in natural anodized aluminum. Further configurations and colors on request.

Request for a quote

AAAGILER GMBH

Germany

Customised labelling with large, clearly visible letters, numbering, hazardous substance symbols, company logos, etc.

Request for a quote

R+L HYDRAULICS GMBH

Germany

High quality at a fair price Many years of experience Fast, reliable delivery Customer specified manufacturing

Request for a quote

BS BODENSTECKDOSEN SYSTEMTECHNIK GMBH

Germany

Floor tank 1206 for 6 units. Very compact floor box made of solid aluminum with an anodized aluminum look. Simple assembly, ideal for retrofitting sockets and network connections. Further equipment variants on request.

Request for a quote

GSW SCHWABE AG

Germany

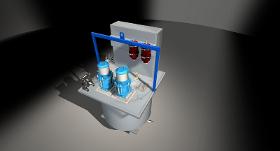

electric compact control with one or two 10l pressure tanks pressurized dispensation made especially for high viscosity lubricants pulsedependent flow control (0 – 99 pulses/min) dispensation time and delay after the incoming signal electrically adjustable via initiator

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The Nova cooling tanks by FESSMANN convince with their highquality processing and special hygiene designs. This means Allround jointfree welding, use of special antidirt edges and a tank bottom inclined towards the drain. This way, dirt deposits are a thing of the past and cleaning becomes child's play! Unique heat insulation ensures best efficiency Volume can be chosen between 300 – 1000 l Hygienic stainless steel design with antidirt edge Delivery in prefabricated construction considerably shortens the assembly times

Request for a quote

BDSENSORS GMBH

Germany

The screw-in transmitter LMK 351 has been designed for measuring small system pressure and level measurement in container. The LMK 351 is based on an own-developed capacitive ceramic sensor element. Usage in viscous and pasty media is possible because of the flush mounted sensor. For the usage in aggressive media a pressure port in PVDF and the diaphragm in AI2O3 99.9 % is available. An intrinsically safe version complete the range of possibilities. Features — nominal pressure: 0 ... 40 mbar up to 0 ... 20 bar — accuracy: 0.35 % (opt. 0.25 %) FSO — pressure port G 1 1/2" for pasty and polluted media Optional Features — IS-version Ex ia = intrinsically for gases and dusts — pressure port PVDF for aggressive media — diaphragm pure ceramic (99,9 % Al2O3) — customer specific versions

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Our supply tanks are suitable for all common lubricants. No matter if graphite containing, salty or oil based products, the Jerko spraying unit is equipped for all applications. Standard sizes form 250 litres up to 2.000litres Due to the special surface and well thought-out cleaning function, the unit is durable and requires low maintenance. For cleaning, the complete cover can be lifted off with a few simple movements. This modular system allows easy replacement of the components. The necessary pressure to supply the spray equipment is generated by a piston pump developed by Jerko with a transmission ratio of 1:3.

Request for a quote

KLN ULTRASCHALL AG

Germany

The machine of series KT can be applied universally. It is designed for the industrial part cleaning. Application fields: metal degreasing, electrical industry, optical industry, medical technology, maintenance and service etc. The compact design of the machine as 3-tank system guarantees a high cleaning quality together with space-saving location. The basic version consists of a heated ultrasonic tank (tank 1) and heated cascade rinsing (tank 2 and 3). Additionally a separate dryer corresponding to the size of the compact unit can be made available. The tanks are incorporated in a solid frame. Optionally a stainless steel base frame can be delivered. Armatures, tank and frame are made of stainless steel. All valves can be easily operated at front of the machine. All electrical operating elements are on the front of the machine. They are each assigned to the tanks.

Request for a quote

KLN ULTRASCHALL AG

Germany

Ultrasonic cleaning tanks of series SW 12, SW 25 and SW 40 are compact tabletop cleaning devices for industrial purposes. The serial version includes a cover with handle. The cleaning tanks can be equipped alternatively with frequencies of 30 or 40 kHz or in combination 30/40kHz. On the front the ultrasonic operation can be set nonstop or for a limited period. The ultrasonic generators are integrated in the stainless steel housings. The devices are equipped with a heating with thermostatic regulation installed at the outside of the tank. It is set on the front. The tanks are made of stainless steel, here the SW40 – SW90 are built in welded design. On the bottom they have a residual clearance. Heated and cold cleaning tanks complete the program. Only aqueous cleaning agents are permitted in the cleaning tanks.

Request for a quote

KASPAR SCHULZ BRAUEREIMASCHINENFABRIK & APPARATEBAUANSTALT GMBH

Germany

You can expect only the highest quality pressure and bright beer tanks from Kaspar Schulz. The new Pressure Equipment Directive 97/23/EC has been in effect since May 5th, 2002. Surveillance of the QS-System is carried out by TÜV-Süddeutschland (0036). Every pressure tank built by Kaspar Schulz complies with the AD-2000 technical guidelines, which ensures that the customer is spared of any long test intervals, in comparison to other European standards. Please look into our competitors’ rates —higher costs for future inspections could arise. Let the impressive appearance of our tanks and their numerous features do the convincing: Suitable for all types of beer, plus carbonated non-alcoholic and mixed beverages given that they are principally manufactured for a 3 bar operating pressure Welded and ground surfaces create a sleek appearance Finished model is fully calibrated Easy-to-clean contents display

Request for a quote

KASPAR SCHULZ BRAUEREIMASCHINENFABRIK & APPARATEBAUANSTALT GMBH

Germany

The top tier of aesthetic and technology: With their flawless welding seams and trademark look, the KASPAR SCHULZ tanks are convincing in every aspect of brewery plant manufacturing. Thanks to our in-house only production, we can offer you customized plans that precisely tailor the tank measurements to the room height in your facility. The tanks are suitable for all types of beer, plus carbonated non-alcoholic and mixed beverages given that they are principally manufactured for a 3 bar operating pressure Ideal cleanup thanks to rounded manholes Temperature measurement using a contact sensor The bung apparatus (pressure regulator) can be integrated into the tank cleaning circuit without disassembly Welded and ground surfaces create an attractive appearance All piping is mounted mechanically (thus, without a welding arc). Piping is curved and therefore meets the highest biological safeguard requirements Minimal installation costs thanks to pre-piping

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM FOR THE COST EFFECTIVE REFURBISHING OR VOLUME EXPANSION OF CONTAINERS OR TANKS Changing conditions, material wear, a change to the filling medium – these are just a few of the factors that lead to the replacement of containers used in industry or at municipal sewage treatment plants. Quantities change and existing containers become too small – these are also problems that frequently arise. In such cases, the mobile machine technology from Lipp using the LIPP Double Seam System or the LIPP welding technique offers a solution that is as simple as it is cost effective, while being extraordinarily stable. Containers can be installed on site in any size required and can be placed in an existing steel or reinforced concrete basin using a mobile crane. The existing container volume is utilised, eliminating the need for expensive demolition work. Utilisation of the existing container volume High stability, leak tightness and safety Continuous adaptation to existing container

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

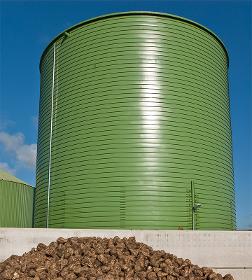

FOR STORING BIOMASS TO BE USED FOR ENERGY PRODUCTION OR ANIMAL FEED The LIPP System is based on a world wide unique and genuinely simple principle of tank production. Steel coils, machines and accessories are transported to the construction site, the production of the tank takes place on site – fast, efficiently and flexibly in height and diameter. In an automated, two stage process, a profile is formed from the steel strip which is joined in a second step – at the same time, the container rotates spirally. The tight and stability supporting connection of the steel band can be effected by the LIPP Double Seam as well as the LIPP Welding Technology. Compact and space saving High functional safety Reduced retention time in the digester Reduced energy losses during storage Low maintenance and durable Automatic feeding Storage losses as a result of oxidation are avoided

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The self supporting, lightweight diaphragm construction made of stainless steel – with high mechanical strength and resistance to ageing – enables tanks with diameters of up to 50 m to be spanned. The stainless steel not only provides support but also seals off the tank and can withstand snow loads and high winds. The Lipp stainless steel diaphragm cover is corrosion resistant, gas and vapour diffusion tight and provides reliable protection against UV radiation and mechanical damage. The lightweight design of the diaphragm makes it ideal for covering volatile and explosive substances and prevents components from flying around in the event of an explosion. Prefabrication of the diaphragm at the factory eliminates the need for welding work to be carried out at the construction site.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

ON SITE PRODUCTION FLEXIBILITY WITH CONTINUOUSLY VARIABLE DIMENSIONS Special circumstances and requirements often call for containers which cannot be produced using standard solutions. This is where special tanks and silos which can be adjusted to suit prevailing conditions and provide individual solutions are required. The LIPP System offers a variety of possible solutions to a wide range of problems in the form of welded or folded designs. Steplessly adjustable diameters and heights enable tank dimensions to be individually adapted to the prevailing conditions. In addition, on site installation only requires a minimal amount of space, for example enabling containers to be constructed in buildings or other situations where there is limited space available. Tank in tank solutions can also be realised using the LIPP System. Tank in tank solutions Container expansion, e.g. of concrete containers Installation inside buildings Mounting on platforms Mounting on various substructures

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SOLUTION TO EFFECTIVELY STORE EXCESSIVE HEAT FROM BIOGAS PLANTS – FROM 2,000 TO 6,000 M³ The LIPP® Thermal Storage Tank is a customized solution to effectively store excessive heat from biogas plants, biomass heating plants, solar plants or other heat sources. The carbon steel tanks are fabricated on site with the patented automated LIPP® Welding Technology. The horizontal MAW welding process enables the infinitely variable production of tanks up to 6,000 m³ volume with horizontal welding only. The large volume, above ground storage tanks are fitted with all necessary safety and operation equipment. Additional, individual components according to client’s specification can be considered. The roof and wall insulation is individually adapted to local conditions. The LIPP® Thermal Storage Tanks operate at atmospheric pressure, at a temperature of up to 95° C and are suitable for use with heating water. No additional nitrogen system necessary.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

IN STEEL AND STAINLESS STEEL FROM 50 – 10,000 M3 LIPP welded storage tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP and can be constructed with steplessly adjustable volumes of 50 to 10,000 m³ according to the application. LIPP offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to high alloy stainless steels. The automated process meets the highest quality standards. LIPP storage tanks can be produced within a very short time, either on site in the open air or inside a building. The special circumferential profile ensures additional stability compared to conventional processes. KEY BENEFITS Three different welding processes based on the LIPP system and adjusted to the application

Request for a quote

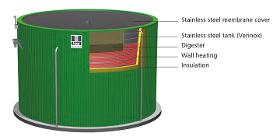

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

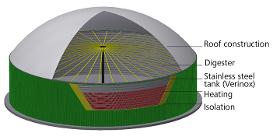

Containers are available in a wide range of sizes, with diameters of 3 m up to 40 m and volumes up to more than 10,000 m3. WIDE CHOICE OF MATERIALS There is a wide variety of materials to choose from, ranging from steel and galvanised steel through to high alloy stainless steels (e.g. 1.4301 [304] or 1.4571 [316Ti]), according to the requirements of the storage medium in each case. Developed in house, Verinox is a combination of galvanised steel for the outside and stainless steel for the inside of the container. Verinox is an impressive material due to its excellent cost/benefit ratio

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The automated assembly technology in the LIPP Double Seam System enables the fast construction of stainless steel tanks which has a positive effect on investment costs. Efficient production on site, minimal installation space and a short construction time are key features of this flexible construction technology.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The range of material grades available and individually customisable pumping and stirring technologies provide optimum boundary conditions for any substrate composition. Pre or post treatment of the substrate can be carried out by installing additional tanks (e.g. hydrolysis, sugar beet silos and post digesters). With Lipp tanks for biogas plants which are built and used all over the world, you will benefit from 50 years of experience in plant and tank construction. They are constructed using VERINOX stainless steel which is characterised by maximum leak tightness and high quality. Stainless steel digester with a digester chamber volume of 100 to 10,000 m3 Wide range of tank roofs With or without optional gas accumulator Flexible stirring technology which can be adapted to the digester and substrate Smooth internal walls and uniform temperature distribution

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The central agitator has a low energy requirement to ensure mixing and ensures optimum biological digestion. This is helped by the smooth internal walls (largely without any internal attachments) which prevent substrate deposits. As an option, an external heating system can be added to the digester, ensuring an even temperature distribution thanks to the good heat transfer properties of the steel. The central agitator has a low energy requirement to ensure mixing and ensures optimum biological digestion. This is helped by the smooth internal walls (largely without any internal attachments) which prevent substrate deposits. As an option, an external heating system can be added to the digester, ensuring an even temperature distribution thanks to the good heat transfer properties of the steel. MAXIMUM LEAK TIGHTNESS AND PRACTICAL ON SITE CONSTRUCTION With Lipp digesters you will benefit from over 50 years experience in plant and tank construction.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Stainless steel digester with a digester chamber volume of 200 to 5000 m3 External panel heating and insulation Optimised diameter to height ratio for optimum mixing and minimal stirring Flexible stirring technology which can be adapted to the substrate and digester Stirring technology can be maintained without having to empty the tank

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The automated assembly technology in the LIPP Double Seam System enables the fast construction of stainless steel tanks, which in turn has a positive effect on investment costs. The benefit for you flexible construction technology with efficient production on site requiring minimal installation space and ensuring a short installation time. The smooth internal walls of the LIPP Digesters (largely without any internal attachments) ensure gentle, uniform mixing while keeping energy consumption low. The external heating system guarantees uniform temperature distribution in the digester. These mechanical and thermodynamic benefits with LIPP digesters mean short retention times.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The high functional safety, especially for heating and stirring technology, ensures a low demand for process energy and this is combined with the benefits of minimal maintenance requirements and a long service life.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

MADE FROM VERINOX STAINLESS STEEL OR GALVANISED STEEL WITH VOLUMES RANGING FROM 40 M3 TO 10,000 M3 Both industry and communities require professional solutions for plant and tank construction and for the storage and treatment of liquids, as well as flexibility in terms of size, choice of material and equipment. When constructing liquid storage tanks, the selection of the best material is an important quality factor. Municipal/industrial waste water and sludge or certain processing, intermediate and end products from the chemical, pharmaceutical and food processing industries set high requirements regarding the tank material, for example. LIPP offers a variety of materials, ranging from galvanised steel through the combination material Verinox to high alloy stainless steels. APPLICATIONS Waste water tanks Sewage sludge tanks Process water tanks Storage tanks Firefighting water tanks Mixing and compensation tanks Buffer Tanks Stackable sludge tanks Storage containers

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Stainless steel digester with a digester chamber volume of 100 to 2500 m3 Integrated gas accumulator – fixed in gutter for high operating safety Optimised diameter to height ratio for optimum mixing and minimal stirring Low maintenance, external panel heating system Flexible stirring technology which can be adapted to the substrate and digester Stirring technology can be maintained without having to empty the tank

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

There is a variety of roof constructions that can be used to cover LIPP Post Digesters properly. The range includes foil roofs, single and double skin roofs and double diaphragm roofs as well as the high quality LIPP stainless steel diaphragm cover.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The reference information is then applied during service and inspection visits to ensure that the expected performance levels are being met. All inspections are carried out by fully qualified Lipp professionals, who utilise the latest analytics equipment. Efficiency tests can be run on each system and cross referenced – helping highlight any operational issues that may have occurred. This comprehensive analysis further notifies Lipp and the end user which parts of the system may need particular attention or replacement. Qualified Lipp technicians also have the skills needed to deal with more specialised installations, such as anaerobic digestion tanks for biogas production. By providing the same level of technical proficiency as the original installation team, Lipp safeguards the quality level of maintenance activity and the tank itself. Lipp technicians also impart knowledge and training to the end users, so that everyone can become familiar with their system

Request for a quoteResults for

Tanks - Import exportNumber of results

365 ProductsCountries

- Germany (365)

- Bonn, Düsseldorf and North Rhine and Westphalia (59)

- Frankfurt am Main and Hesse (8)

- Hamburg and region (1)

- Hannover and Lower Saxony (13)

- Kiel and Schleswig-Holstein (3)

- Leipzig and Saxony (3)

- Munich, Nuremberg and Bavaria (26)

- Potsdam and Brandenburg (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (251)

Company type

Category

- Tanks, metal (88)

- Agricultural systems and equipment (64)

- Silos, farm (64)

- Storage tanks (63)

- Silos, plastic (60)

- Wine fermentation tanks (19)

- Electronics - import-export (17)

- Cleaning, tanks and cisterns (6)

- Pumps (6)

- Cooling tanks (4)

- Cleaning machines, industrial (3)

- Construction machinery (3)

- Sensors (2)

- Compressors (2)

- Measurement and regulation equipment and instruments - pressure (2)

- Water - production and distribution (2)

- Tanks, plastic (1)

- Brewing - machinery and equipment (1)

- Cooking and smoke-curing equipment for delicatessens (1)

- Laboratory equipment and instruments (1)