- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water treatment system

Results for

Water treatment system - Import export

SOLARSPRING GMBH MEMBRANE SOLUTIONS

Germany

"SolarSpring's MBS-Wall-Mounted is a compact and innovative water treatment system. The system guarantees a reliable and safe water supply from polluted and microbiologically contaminated water sources without the use of chemicals. Technical data: Nominal flow rate: 100 - 600l/h Energy consumption: 8W Weight: 32kg"

Request for a quote

SOLARSPRING GMBH MEMBRANE SOLUTIONS

Germany

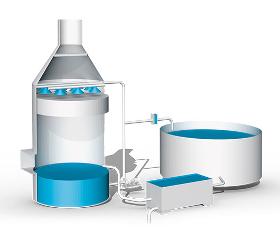

"Clean water with clean electricity Billions of people still have no access to clean drinking water or lack adequate sanitation. Residents of rural areas are particularly affected. If drinkable water is needed far away from any infrastructure, SolarPurification can help. The system can produce up to 200,000 litres of clean drinking water per day even from heavily polluted surface and ground water. Clean drinking water without chemicals Several treatment stages make it possible that the drinking water is not only clean but also safe. The SolarPurification filters 99.999 % of all bacteria and viruses from the existing water - and this completely without the use of chemicals. This is made possible by a combination of ultrafiltration, activated carbon filtration and UV disinfection. High-quality components, automatic operation with PLC and online monitoring characterize this compact water treatment system. Low maintenance and solar powered

Request for a quote

SOLARSPRING GMBH MEMBRANE SOLUTIONS

Germany

"The MBS-Outdoor from SolarSpring is a compact and innovative water treatment plant.The system guarantees a reliable and safe water supply from contaminated and microbiologically contaminated water sources without the use of Chemicals. Tecnical data: Nominal flow rate: 50-200l/h Energy consumption: 40W Weight: 22kg"

Request for a quote

IGUS® GMBH

Germany

- Low-maintenance system for travel up to 100 m - Other sizes and versions available, travel up to 200 m and more with E2 roller e-chains® - Protection against weather and dirt exposure - Cost-effective and fully enclosed complete solution - Standardized and modular design - Simple wall assembly or optional floor mounting - Cable lengths up to 50% shorter than festooning, low-profile installation and no cable junction - Cables are at all times guided with a defined bending radius, and tensile forces are absorbed by the e-chain® - Cables cannot hook, jam, or tear - No slip ring contacts (as is the case on motor drums) -Cables or hoses can easily be retrofitted at any time Reduce electricity costs - direct drive due to scraper, no additional drives needed (as is the case on motor drums) Scraper arm (e.g. as mechanical connection to the scraper carriage) optionally available - we document the situation on-site and will propose a customised solution

Request for a quote

FLOTTWEG SE

Germany

Honored with the German Innovation Award 2019, the Xelletor series is one of the greatest achievements in the field of sewage sludge. Dewatering sewage sludge is standard for wastewater treatment plants and since it usually has to be transported away, operators have an interest in separating as much water as possible from the sludge. This saves weight and thus reduces costs. Savings of up to 10% in sludge volume and 34% in energy consumption are possible. Our Xelletor high-performance centrifuge inspires customers all over the world with the many years of technical know-how and innovative spirit behind it.

Request for a quote

FLOTTWEG SE

Germany

Proven know-how meets state-of-the-art technology. This is the best way to describe the new Flottweg decanter C series. We also have the optimal solution for the very large wastewater treatment plants. The combination of our own Simp Drive® drive system, which has been in use since 1994, and Recuvane®, which allows flexible and simple retrofitting as well as targeted discharge of the centrate water, sets new standards for Flottweg in separation technology.

Request for a quote

FLOTTWEG SE

Germany

Flottweg C series decanters around the world process 25 million liters of sewage sludge per hour. The dewatering and thickening of sewage sludge plays a decisive role in the wastewater treatment process. Requirements for the quality and efficiency of sewage treatment plants increase year after year, not least driven by the increasing costs of energy and disposal. As a result, the state of the art is now to use decanter centrifuges to dewater and/or thicken the incoming sludge. Flottweg developed the decanters of the C series especially for this purpose. The C7E represents the largest of all the C machines. The C7E increases the proportion of dry substance in the sludge, thereby reducing its volume and weight (due to loss of water). That means that operators need to dispose of, recycle, or burn less sludge. The result: enormous potential savings for the operators of sewage treatment plants.

Request for a quote

FLOTTWEG SE

Germany

Innovationen sind Flottweg Spezialität. Unsere Xelltorbaureihe spiegelt Erfindergeist, langjährige Erfahrung und technisches Know-How in einer Maschine wieder. Auf Kläranlagen ausgelegt ist die X5E für mittelgroße Kläranlagen die optimale Lösung, wenn es um Schlammentwässerung und Schlammeindickung geht. Die Kosteneinsparung hinsichtlich Entsorgung und Transport ist für viele Kläranlagenbetreiber der ausschlaggebende Punkt, sich für den Flottweg Xelletor zu entscheiden.

Request for a quote

FLOTTWEG SE

Germany

Flottweg has developed a unique centrifuge concept especially for the high-level dewatering of sewage sludge: The Flottweg Xelletor series. For the wastewater treatment plant operator, dewatering offers enormous savings potential. The costs for transport and disposal of dewatered sewage sludge often account for 80% of the operating costs of mechanical dewatering. The dewatering performance of the Xelletor machine is significantly better than that of our predecessor models. And it's setting new standards in terms of throughput, dry substance, and polymer and energy consumption.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KME series was developed as a wet-installed centrifugal immersion pump for stationary use in tanks and basins. The direct-coupled pump with plain bearings is suitable for pumping and circulating neutral and chemically aggressive liquids in the chemical industry and process engineering, in electroplating and surface technology, in washing systems and water treatment plants, for sump drainage in industrial and municipal waste disposal plants or as a circulation pump in gas scrubbers and heat exchangers. * with various plain bearing designs * available in immersion depths from 600 - 1500 mm Features & Advantages * Compact dimensions * Abrasion resistant material combinations possible * Extremely low-vibration and low-wear operation * All wetted parts made of corrosion resistant plastic * Self-centering alignment in the bearing shell

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

Our products are unseen aides installed in many electric machines and motors: from huge plants to compact hand-held devices. Are you looking for a entirely specialised solution for current and data transmission? We produce the right carbon brushes and brush holders for the broad range of applications which characterises the field of electrical and plant engineering. This includes filling and packaging machinery, waste water treatment plants or revolving door systems, just as much as the manual electrical appliances which provide professional and hobby craft workers with reliable service. And these are a just a few examples. As we are system suppliers, you can be absolutely sure: MACK supports you throughout the entire development process. MACK supplies first-class OEM quality and durable replacement parts from in-house production. MACK makes your ideas come true!

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Water treatment for steam boiler systems — Prevention of corrosion in the boiler — Outstanding deaeration efficiency and reduced consumption of chemicals with WSM-V complete deaeration system — Partial deaeration module WSM-T for small systems — Fast and easy planning, installation and acceptance appropriate to the steam boiler in question — Requirement for positive suction head allows for ground-level installation and easy commissioning

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

A complete centralised cooling plant, including the required peripherals, can be set up in the absolute shortest possible time at the subsequent place of installation and is immediately ready for use by means of prefabrication and installation in a container. This way, the otherwise high investments for an operating building, the costs for installation and start-up of the plant are reduced. Container cooling plants almost have no limitations in terms of their capacity and variety of possible combinations. They are supplemented by peripheral systems such as water treatment and water preparation systems or compressed air compressors. A series of different cooling systems and the combined systems composed of these units are primarily available: Chiller Heat pump systems for heat recovery Cooling tower combined with a KU system as a closed, clean cooling circuit Air heaters for direct recovery of heat hermeticool-units hermeticool hybrid-units

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Rack & pinion jack for lifting, lowering, adjusting and fixing of mechanical components, devices, machines etc., load 0,5 t up to 10 t Rack & Pinion Jack, wallmounting 1659 Rack & pinion jack with flange, wallmounting, for pulling and pushing load, capacity 1,5 - 5 t

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

A bio scrubber combines physical scrubbers with a biological activation unit. In this process, air polluted with a wide variety of pollutants is cleaned with the aid of a washing liquid which is loaded with microorganisms and biocatalysts (various enzymes) taken from nature. The washing water absorbs the exhaust air and pollutants from the air. Subsequently, added microorganisms oxidise them. These microorganisms use the air pollutants as substrate and nutrient medium and convert them into naturally formed decomposition products such as CO2, water, and biomass. Here, the washing water is continuously regenerated and used in a closedcircuit water treatment system. TYPICAL APPLICATION AREAS These plants are primarily used for watersoluble ingredients of the exhaust air. The usual pollutants that are filtered from the exhaust air with the help of bio scrubbers include aldehydes such as formaldehyde, alcohols, ketones and other hydrocarbon compounds.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS Decentralized application Optimal load-case design Optimized flow stream design Vibration-optimized design Leaflet: E-3015-Waterbath Heater / Type VH OPTIONS FOR HIGH PRESSURE TUBE BUNDLE Customer-specific design for various design codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.) Design according to TEMA Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Customer-specific nozzle arrangement Water jacket design as pressure vessel Water tank vessel for hot water> 100 ° C GENERAL Indirect water bath heaters type VH are heat exchangers (heat exchangers) which can heat the gas decentrally if no hot water treatment (for example a boiler system) is available. The heating of the gas is necessary in order to counteract the Joule-Thomson effect during pressure reduction or to provide a defined gas temperature for the following system components. The most common...

Request for a quote

ASSFALG GMBH

Germany

The new Enviro 1000 is an automatic water treatment system that purifies the process water and compound produced after vibratory finishing and reconditions it for renewed vibratory finishing operations. The centrifuge cleans and recycles the process water by separating the solid particles and often also oils from the process water and depositing them as solid sludge on the edge of the centrifuge basket used for this purpose. This cycle of processes: Vibratory finishing, cleaning and recycling the process water and finally reusing the process water in a renewed vibratory finishing process saves costs and is extremely environmentally friendly.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SOLARSPRING GMBH MEMBRANE SOLUTIONS

Germany

"The rEvap technology is the perfect solution for small and medium-sized companies that want to close material cycles and minimize disposal costs. The plants are equipped with a plate module. We would be pleased to carry out appropriate preliminary tests for you. Technical details: For process water / waste water up to 1 m³/h Fully automatic Controlled via Siemens SPS Adaptable according to customer requirements All channel geometries possible Suitable for endurance run"

Request for a quote

SOLARSPRING GMBH MEMBRANE SOLUTIONS

Germany

"The main customers of our MDLab are universities, institutes and companies who conduct research and practical studies on membrane distillation. This highly precise laboratory set up is fully automatic and suitable for the investigation of all aspects of the membrane distillation process as well as material research e.g. on membranes. The MDLab is equipped with a flexible test cell, which can encompass any MD channel configuration or material sample. Our MDLab system can be visited in Freiburg on appointment for a full demonstration. Technical information: 120 cm x 140 cm x 85 cm Fully automated Tablet controlled (Terra tablet included) Customizable according to specific rquirements All MD channel configurations possible Suitable for continuous operation Power supply required"

Request for a quoteResults for

Water treatment system - Import exportNumber of results

20 ProductsCountries

Category

- Water treatment, industrial - systems and equipment (9)

- Water treatment products (5)

- Treatment of industrial waste water (1)

- Pumps (1)

- Air purification - equipment and systems (1)

- Finishing of surfaces - machinery (1)

- Grinding - steels and metals (1)

- Plastics - machines and material for industry (1)

- Processing and recycling of waste (1)

- Water retreatment - equipment and installations (1)