- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- weld nuts

Results for

Weld nuts - Import export

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Designed to be used as filler ports for hydraulic reservoirs, allowing the reservoir to breathe whilst protecting it from contamination found in harsh environments Types ▪ SES 1 (Screw-in version) ▪ SES 2 (Welded version) Features ▪ Cap diameter of Ø62 mm / Ø2.44 in ▪ Screw-in version, equipped with male Metric ISO thread M45 x 2 and lock nut, or welded version with welding socket made of Steel (1.0718), untreated ▪ Supplied with 45 μm air filter element Materials ▪ Breather cap made of Polyamide (PA) ▪ Breather body / stud made of Polyamide (PA) ▪ Nut (type SES 1) made of Steel (1.0718); ▪ Polyamide (PA) available on request ▪ Welding socket (type SES 2) made of Steel (1.0718), untreated; Stainless Steel (V2A) available on request ▪ Air filter element made of Sintered Bronze ▪ Basket made of Polyamide (PA) ▪ Dipstick made of Steel (1.0718) ▪ Sealings made of NBR (Buna-N®) Consult STAUFF for alternative materials. ▪ Plastic basket (300 μm) ▪ Metal dipstick

Request for a quote

ECKOLD GMBH & CO. KG

Germany

ECKOLD extrusion embossing allows for direct screwing in sheet metal and does away with press-fitted or welded nuts. The embossed structure formed in the process increases the number of turns for the screw and thus enhances its grip. In addition, extrusion embossing allows for higher torques than would be possible with simple screwing of multiple sheets. The technique is suitable for use in virtually all industries where sheet metal is machined and joined - stationary, robot-controlled or as a punch press system. This offer includes: Servo motor-driven extrusion embossing system • Embossing punching frame, horiz. throat 150 mm stationary or robot-guided • Servo motor-driven Press force approx. 58 kN Working stroke approx. 100 mm • Tool holder • Control cabinet incl. software ECKOLD VISU Embossing inserts are not included in the scope of delivery. Scrap suction/micro spray system on request. Contact us for a customised offer!

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

We accept responsibility for the whole process of production. On the one hand, we set outsourced items or provided parts like Press-in bolts Clinch studs Ball studs Weld screws Weld nuts into complex assembly groups. On the other hand, we offer downstream services like Thread cutting Slide grinding Defatting Special packing operations (in trays / blister packaging, wound on spool, packed in layers) Your needs and wishes always have priority and always will have. For that purpose we cooperate with reliable suppliers, who take charge of downstream surface treatment like: Galvanising Chrome-plating KTL-coating Silver-plating Hardening Press tempering Powder coating On your wish we guarantee particle purity and silicone-free packing.

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

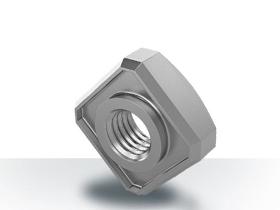

With PIAS® pierce-clinch nuts (square) and RIVTEX® (ROUND) a non-detachable metal fastening can be created at optimum cost. The pierce-clinching technology is suitable for steel and aluminium sheets, causes very little cost for inspection and control, and allows several pierce-clinch screws to be processed in a single stroke. PIAS® and RIVTEX® pierce-clinch nuts offer the following advantages over welded nuts: corrosion-resistant no weld spatter on the thread no thermal weakening at the fastening position self-piercing higher torque requirements high process reliability in fully-automated processing flush-mounted processing processing can be manual, semi or fully automated self-locking thread possible

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Weld nuts - Import exportNumber of results

4 ProductsCountries

Company type