- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- horizontal centrifugal pumps

Results for

Horizontal centrifugal pumps - Import export

LUTZ PUMPEN GMBH

Germany

The TMB series was specially developed for installation in small systems and apparatus. The single-stage Centrifugal pump offers robust technology in the smallest space. * Drive is via a magnetic coupling * Typical applications: Acids, alkalis, acid and alkali mixtures, solvents, alkaline degreasing baths, electroplating baths, photographic chemicals Features & Advantages * Variable connection options * Compact dimensions, performance in line with requirements * Connections with BSP thread or hose nozzle * Ideal for mobile use * Motor and pump are mechanically separated

Request for a quote

LUTZ PUMPEN GMBH

Germany

Application examples: Series TMB was developed particularly for installation in small systems and equipments. The single-stage pumps offer rugged technology in a minimum of space. Features: Driven via magnet coupling Motor and pump mechanically separated Performance range max. 65 l/min and 8 m delivery head Suitable for densities up to 1.1 kg/dm3 and viscosities up to 20 mPas Housing material PP (GF) or ECTFE /CF) Connections with BSP-thread or hose connector Benefits: No dynamic shaft seal Pump housing hermetically sealed Compact dimensions, tailor-made performance Ideal for mobile applications Variable connection options

Request for a quote

LUTZ PUMPEN GMBH

Germany

Application examples: Ideal for the low to medium performance segment in plant engineering and process equipment manufacturing. High-quality housing and bearing materials enable a tailor-made adaptation to almost every pumping application. Features: Driven via magnet coupling Motor and pump mechanically separated Performance range max. 200 l/min and 12 m delivery head Suitable for densities up to 1.8 kg/dm3 and viscosities up to 40 mPas Housing material PP (GF) or ECTFE /CF) Connections with BSP-thread or hose connector Version GX approved according to ATEX Directive 2014/34/EU, Category 2 Benefits: No dynamic shaft seal Pump housing hermetically sealed Version “R” conditionally safe to run dry Also for liquids with a high specific density Variable connection options

Request for a quote

LUTZ PUMPEN GMBH

Germany

Application examples: Suitable for high pump capacities. With the TMR G3 series, Lutz presents a reliable magnetic coupling pump with a patented magnetic axial thrust compensation that easily handles even critical application conditions. Features: Drive via magnet coupling with patented magnetic axial thrust compensation Motor and pump mechanically separated Performance range max. 48 m³/h and 42 m delivery head Suitable for densities up to 1.8 kg/dm3 and viscosities up to 150 mPas Housing material PP (GF) or ECTFE /CF) Connections with BSP/NPT thread or ISO/ANSI flange Version GX approved according to ATEX Directive 2014/34/EU, Category 2 Benefits: No dynamic shaft seal Pump housing hermetically sealed By “magnetic axial thrust compensation” the bearing system “R” is suitable for dry running Also for liquids with a high specific density Variable connection options Metallic protection plate protects the pump housing against mechanical damage

Request for a quote

LUTZ PUMPEN GMBH

Germany

Application examples: Suitable for medium-sized performance ranges. With the TMR G2 series, Lutz presents a reliable magnetic coupling pump with a patented magnetic axial thrust compensation that easily handles even critical application conditions. Features: Drive via magnet coupling with patented magnetic axial thrust compensation Motor and pump mechanically separated Performance range max. 30 m³/h and 30 m delivery head Suitable for densities up to 1.8 kg/dm3 and viscosities up to 150 mPas Housing material PP (GF) or ECTFE /CF) Connections with BSP/NPT thread or ISO/ANSI flange Version GX approved according to ATEX Directive 2014/34/EU, Category 2 Benefits: No dynamic shaft seal Pump housing hermetically sealed By “magnetic axial thrust compensation” the bearing system “R” is suitable for dry running Also for liquids with a high specific density Variable connection options

Request for a quote

LUTZ PUMPEN GMBH

Germany

The AM series was specially developed for for the medium performance segment in plant and apparatus engineering. High-quality housing and bearing materials enable adaptation to almost any conveying task as required. * Drive is via a magnetic coupling * Examples of applications: Acids, alkalis, acid and alkali mixtures, solvents, alkaline degreasing baths, electroplating baths, photographic chemicals Features & Advantages * Variable connection options * Compact dimensions, performance in line with requirements * Also for liquids with high density * Version "R" conditionally suitable for dry running * Motor and pump are mechanically separated * Connections with BSP thread or hose nozzle

Request for a quote

FLUX-GERÄTE GMBH

Germany

The horizontal Drum and container pump F 430 TR is ideal for conveying media from IBCs, tanks and other containers with low level outlet. E.g. if a tank is not accessible from the top, or if the spatial conditions do not allow use of a vertical pump. For cleaning, the pump can be easily and quickly taken apart in its two main components. The pump is available in stainless steel or polypropylene. The stainless steel version can also be used in hazardous areas. Benefits: - For containers with floor drain - Provides highest flexibility in installation and mobility - Can also be used at low ceiling heights - Stainless steel version for use in hazardous areas - Can also be integrated into pipe systems - A horizontal centrifugal pump that can be used with different FLUX motors

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Horizontal End-Suction Pumps are centrifugal inline pumps with a compact design where the impeller is mounted onto the extended motor shaft. These pumps are not self-priming and must be gravity fed. All pumps are equipped with a single mechanical seal. Upon request a second mechanical seal is available to allow for dry-running (-GD). This pump series is designed for horizontal installations next to a tank and for pumping air entrained coolant fluids, such as water-soluble coolants or cutting oils, as they occur in high speed turning, milling or grinding applications. The SBA pumps are equipped with the user-friendly (SAE) flange connection which allows for either vertical or horizontal pipe connection and the connection of a pressure gauge with G 1/4. Volumetric delivery: up to 2200 l/min Delivery head: up to 62 m Please contact us for delivery quantity.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Horizontal End-Suction Pumps are centrifugal inline pumps with a compact design where the impeller is mounted onto the extended motor shaft. These pumps are self-priming after initial filling. All pumps are equipped with a single mechanical seal. SBM Pumps are mounted next to or on top of the tank and they are suitable for pumping air entrained coolant fluids, such as water-soluble coolants or cutting oils, as they occur in high speed turning, milling or grinding applications. Volumetric delivery: up to 440 l/min Delivery head: up to 20 m Please contact us for delivery quantity.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Horizontal End-Suction Pumps are centrifugal inline pumps with a compact design where the impeller is mounted onto the extended motor shaft. These pumps are not self-priming and must be gravity fed. All pumps are equipped with double mechanical seal. This pump series is designed for horizontal installations next to a tank and are capable of cutting aluminium chips and similar materials and pumping of these materials along with the coolant fluid. An agitator located at the pump suction helps to break up and separate any large bundles of chips or birds nests which reach the pump suction. The specially made cutting unit (>60 HRC) is cuting chips and the above located semi-open impeller allows with its large clearances to pump the particles along with the coolant fluid from the machine back to the filter. The SBC pumps are capable of handling chip to coolant ratios of up to 1.5% by weight. Volumetric delivery: up to 1400 l/min Delivery head: up to 34 m

Request for a quote

VILLINA LLC

Russia

One of the priority areas in the production of Villina pumping equipment was initially the development of a specialized line of pumps designed for pumping harsh chemical fluids. At present, we are ready to offer you Villina high-end lined centrifugal canned pumps having design life of 20 years for pumping mineral and organic acids, alkalis, salts, oxides and anhydrides, including chlorides, as well as alcohols, esters, aromatic hydrocarbons, ketones, aldehydes and other media which contain various concentrations of mordant substances. Modern technology makes rapid progress, and in place of pumps used earlier for transit of corrosive fluids made of chemically resistant yet expensive steels such as KhN65МV, N70MFV, 06KhN28MDT, lined pumps are widely used now. In accordance with para. 51 of the Safety Rules of chemically hazardous production facilities, corrosion-resistant non-metallic coatings (polyethylene, fluoroplastic) can be used to protect equipment and pipelines

Request for a quote

VILLINA LLC

Russia

The Villina GNGC series horizontal canned centrifugal pumps with magnetic couplings are widely used in oil and gas companies of Russia and its neighbouring countries for transit of explosive and flammable, toxic and corrosive fluids. The horizontal arrangement allows the use of a GNGC as a replacement for technically obsolete and physically worn pumps without significantly changing the geometry of the location and pump lines group assembly systems. 100% tightness, structural design in accordance with API 610, 685 (ISO 13709) standards and explosion-proof design of GNGC pumps are approved by design institutes and Rostekhnadzor for use in projects for modernization, reconstruction or construction of new facilities. GNGC horizontal pumps with magnetic couplings provide for axial position of the suction pipe and radial position of the delivery pipe. The motor and pump body are mounted on supports (OH 2 according to API 610), the drive shaft of the motor

Request for a quote

VILLINA LLC

Russia

Modern petrochemical and gas industries typically use horizontal centrifugal canned pump units with magnetic couplings similar to Villina-GNGC type pumps. They are designed for transiting neutral, corrosive, toxic, as well as explosive and flammable liquids in stationary conditions, the vapors of which can form explosive mixtures with air. Magnetic coupling pumps combine complete tightness, smooth operation, long service life and high maintainability. A sub-type of horizontal pumping units are high-temperature pumps Temperature of the pumped fluid: -50°C to +420°C; viscosity up to 26 cSt; density 2,000 kg/m3 maximum; mass concentration of solid non-abrasive inclusions up to 0.2%; size 0.2 mm maximum Permanent magnets (SmCo) with an operating temperature of up to 450°C are used for operation in these temperature conditions. The pump, a part of the pumping unit, is a single-stage or multi-stage horizontal centrifugal section-type

Request for a quote

VILLINA LLC

Russia

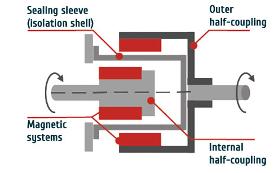

Magnetic couplings are used as transmission mechanisms in modern pumps, which makes it possible to obtain a qualitatively new 100% tight device without making essential changes to the design of the electric drive and the wet end of the pump. At present Villina offers GNVC, GNGC and GNVC-P series vertical, horizontal and semi-submersible centrifugal pumps with magnetic couplings, designed for pumping explosive and flammable, toxic and corrosive fluids (petroleum products, alkalis, acids, alcohols, etc). PURPOSE Magnetic couplings for Villina centrifugal pumps allow for transmission of torque from the electric motor to the pump shaft using magnetic fields generated by permanent magnets instead of mechanical engagement devices. At the same time, there is no need to withdraw the shaft from the pump wet end to the drive device, therefore the wet end can be made in the form of a completely sealed system free of leaks which are typical for pumps with mechanical shaft seals.

Request for a quote

VILLINA LLC

Russia

Our products include Villina-GNGC-2T type centrifugal horizontal pumps with tandem mechanical seals type according to your parameters. These are used for transit in stationary conditions of neutral, corrosive, toxic, as well as explosive and fire hazardous liquids, the vapors of which can form explosive mixtures with air. The units are mainly used by petrochemical industry companies. Parameters of operating fluids (liquids): temperature from -50oС to +400oС viscosity up to 160 cSt density 2,000 kg/m3 max, with a high concentration of particles particle size over 0.2 mm, but not exceeding free passage of the impeller (3 to 12 mm depending on the pump rate) For such conditions, mechanical seals (operating temperature up to 425°C) of well-known companies are used, such as: OOO NPC ANOD, JSC TREM ENGINEERING, UNICHIMTEK Group of Companies and others DESIGN FEATURES The unit consists of a pump, a base plate, an electric motor, a casing and a support system.

Request for a quote

NORTH RIDGE PUMPS LTD

United Kingdom

The SKM horizontal centrifugal multistage pump can be utilised for a wide range of applications in the industrial and marine markets. This multistage pump is designed to pump low viscosity clean or slightly contaminated fluids without the presence of solid or fibrous particles. This SKM pumps are capable of high pressures, up to 55 bar and high flow rates of up to 1000m³/hr and is also very robust due to additional bearings being installed in the pump head, these remove strain away from the motor during operation. Typical Applications & Industries: - Fresh Water and Sea Water - Fuels (Diesel, Petrol and Kerosene) - Boilers - Chemicals - Energy Plants - Mining - Industrial and Construction - and More

Request for a quote

NORTH RIDGE PUMPS LTD

United Kingdom

The ECO SNM close coupled, end suction, single stage horizontal centrifugal pump is standardised to DIN 24255 / EN 733 and can be used for a vast range of applications in the industrial and marine markets. It is designed to pump low viscosity clean or slightly contaminated fluids without the presence of solid or fibrous particles. If required, this pump is available in a vertical version known as the ECO SNM-V series. Typical Applications & Industries: - Water Treatment - Fresh, Grey or Sea Water - Fuels - Diesel, Petrol and Kerosene - Irrigation and Agriculture - Pressurisation - Draining and Dewatering - Building Systems - Marine - Cooling/Heating Conditioning (HVAC) - Chemical Transfer - and More

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LUTZ PUMPEN GMBH

Germany

The TMR series is a reliable magnetic drive pump that easily handles critical operating conditions due to its patented magnetic axial thrust compensation. * Drive via magnetic coupling with patented magnetic axial thrust compensation * Typical applications: Acids, alkalis, acid and alkali mixtures, solvents, alkaline degreasing baths, electroplating baths, photographic chemicals Features & Advantages * Variable connection options * Compact dimensions, performance in line with requirements * Also for liquids with high density * Due to "magnetic axial thrust balancing" the bearing system "R" is suitable for dry running * Motor and pump are mechanically separated * Connections with thread or flange

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Miniature Centrifugal Pumps of the BMK series have been desined for clean watercircuits of up to 160 degree C fluid temperature and up to 7 bar of system pressure. The pumps are equipped with a magnetic coupling. The pumps can be mounted vertically or horizontally. The specific design allows the pumps to operate wear poor. Impellers: peripheral Types of fluid: Industry water Volumetric delivery up to 55 l/min Delivery head up to 58 m Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Immersion Pumps are plain centrifugal pumps with the impeller fitted on the driving shaft extension. They are mounted on top of the container, the pump extension being immersed in the coolant. The maximum coolant level must stay a few mm/inches below the mounting flange. The STA serie offers a (SAE) flange with pressure gauge connection port. The flange can be rotated for either horizontal or vertical pipe connections. Volumetric delivery: up to 5000 l/min Delivery head: up to 120 m Please contact us for delivery quantity

Request for a quote

BRAND SERVICES

Poland

Brand Services represents German ZUWA-Zumpe company in Poland. German ZUWA-Zumpe company supplies the pumps on Polish market. German ZUWA-Zumpe company delivers their pumps to OEM producers. The scope of pumps: Impeller pumps Drill powered pumps Pumps and refuelling systems for diesel Oil pumps AdBlue pumps Gasoline pumps Barell and nad pumps Waste water pumps Side channel pumps Diaphragm pumps PTO pumps Hand pumps

Request for a quote

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. Advantages: the fluid can be taken in at a point lower than the axis of the inlet suction pipe without using a pre-installed vacuum pump. - Purpose: transit of corrosive, toxic, explosive and flammable fluids at insufficient suction pressure; - Pump rate ranges: 0.8 to 450 m3/h; - Head ranges: 3 to 132 m; - Self-priming height (depth): up to 6 metres; - Seal type: magnetic coupling according to API 685 or tandem mechanical seal according to API 682; - Climatic version: for moderate and for moderate and cold climate; - Temperature of the pumped fluid: for GNGC-S, GNGC-S-M up to plus 350°С, for NCG-S up to plus 450°С; - Shaft speed: 1,450 or 2,900 rpm; - Structural design: ОН-2 single-stage back pull-out pump according to API 610 or a single block.

Request for a quote

ALPECO LTD

United Kingdom

We supply; - Sampi RVP Fuel Vane Pumps - Mouvex Blackmer CC8 Cargo Pumps - ATEX Centrifugal Fuel Pumps - RVP Fuel & oil motor pumping sets

Request for a quote

ODDESSE PUMPEN- UND MOTORENFABRIK GMBH

Germany

oddesse-propeller pumps are used for irrigation and drainage of agricultural areas, water-level regulation, oxygen enrichment of breeding water at fisheries, trimming of ships, ferries and tankers and so on. EXECUTIONS - Single-stage centrifugal pumps with open semi-axial impeller - Submersible, rewindable and water-filled motors with protection level IP 68 - Motor cooling through pumped medium that flows around it - Water-lubricated radial and axial slide bearings - Encapsulation of rewindable motor via mechanical seal - Optimal motor filling guaranteed by a volume-compensation system - Rubber-sheathed electrical cable, watertight connected - Continuous operation, switching operation or frequency control - Tandem operation - High-quality materials for application in service, industrial and seawater PERFORMANCE RANGE Delivery volume Q = … 1,000 m³/h Delivery height H = … 24 m

Request for a quote

ODDESSE PUMPEN- UND MOTORENFABRIK GMBH

Germany

The ORCUT TMS, TES, ES and KM grinder pumps are manufactured by ORPU Pumpenfabrik GmbH, an oddesse subsidiary in Oranienburg. These pumps are characterised by a tried-and-tested, effective multiple-grinder system and are operated with motors of efficiency class IE2. ADVANTAGES - Available in standard and explosion-proof versions - Blockage-free operation, either through the use of a patented cutting system or by ensuring the passage of large particles - Stationary or mobile use - Wet or dry installation - DIN flange of sizes DN 32 through DN 150 for PN 6 and PN 10 can be used - Spiral hose can be connected - Comprehensive accessories - Highly efficient - Cost-efficient installation - High operating safety - Long service life - Effluent containing fibres and solids, faeces - Delivered medium temperatures up to 40 °C - Comprehensive service network PERFORMANCE RANGE Delivery volume Q = … 520 m³/h Delivery height H = … 60 m Rated wattage P = … 26 kW

Request for a quote

ACCA PUMPS

United States

ACCA manufactures Centrifugal Pumps ansi type to fit Durco Pumps without any modification to the current installation of pump base and/or inlet and discharge. We stock most pumps and pump parts to fit Durco Pumps Mark III Group I and Group II

Request for a quote

CRAFTMACH ENGINEERED SOLUTIONS INC.

Canada

We are constantly helping companies like your's, OEMs, CMs and Tier 1 to Increase Profitability and Improve Performance by manufacturing and supplying our products and services such as High precision custom finished Casting processed and CNC Machined/ Turned parts with the services of Supply chain and Logistic Management In Europe, UK, USA, Canada, Mexico & India. We can supply you all kinds of high quality custom finish Casting and CNC Machined Pump Parts like Casing, Impellers, Shafts, Spacers, Rings and all other parts at unbeatable quality and cost. We also provide other value added services like Vendor Managed Inventory (VMI), Just In Time (JIT) Delivery, Strategic Planning & Advance Stock Management in Europe, UK, USA, Canada & Mexico to handle risk /uncertainty or urgent demand management. “We commit and challenge that our high precision Casting & CNC Machined/Turned parts with supply chain management services will beat your current quality, cost and performance by 10-25%”

Request for a quoteResults for

Horizontal centrifugal pumps - Import exportNumber of results

28 Products