- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- levellers for sheet metal

Results for

Levellers for sheet metal - Import export

GSW SCHWABE AG

Germany

If you need two Coil Reels to hold one coil, you need a Heavy-Duty Coil Feed Line above all. One that is designed extremely robust and knows to subdue even materials of highest bounce and largest cross-sections.To ensure this, we have taken no heed to cost savings but went by the maximum principle: 2 Coil Reels with high-performance arbors retain the coils from left and right. 2 x 2 hydraulic arms secure them from top and bottom – each with eight tons pressure force, each with hydraulically driven snubber roll. The loading is done with one central lifting gear built into a super-duty running frame for the V-nest. Hydraulic manipulators with pivoting and bending function support the threading of the material. On the receiving end, a Pre-Straightener with 200mm work rolls takes over, after hydraulic edge guides have ensured central entry. Now, if someone asks us our definition of “heavy-duty”: We find 36.000 kilogram coil weight and 2.

Request for a quote

GSW SCHWABE AG

Germany

A perfect combination of space savings and dynamics: the GSW Compact Feed Lines Our Compact Feed Lines are an ideal answer to the challenge of a constraint floor and necessity to process thick materials. Marrying the processes of leveling and indexing into one Feeder-Straightener machine allows for a complete Feed Line with only two individual machines and thus greatly reduces the necessary length. Additionally, the decoupling of the coil mass from the indexing process – achieved through a short loop between Coil Reel and Feeder-Straightener – enables dynamic feeding despite the compact footprint. And, if cross-sections are especially big, the loop can be spared completely, creating yet more space. One more advantage, virtually a by-product out of their very nature, is the quicker set-up of our Compact Feed Lines. This elevates them to not only space- but also time-savers!

Request for a quote

GSW SCHWABE AG

Germany

With Conventional Feed Lines, the focus lies on speed and material surface. That’s why Conventional Feed Lines are equipped with a Coil Reel for pull-off, a Straightener with variable frequency drive a coil loop and a Servo Roll Feed: the loop uncouples the more inert straightening process from the highly dynamic indexing process and thus allows for high line speeds and preservation of the material surface. Since productivity and capacity demands can vary significantly, we have created different control concepts: while small Feed Lines work with a simple pneumatic drag brake at the Coil Reel and an ultrasonic sensor to control the Straightener speed, the large Feed Lines get fully synchronized controls with motor-limited Coil Reels and a smart loop, creating a steady average speed of the whole line. This allows smooth pull-off of high coil weights while the loop remains very calm – in addition, the Servo Roll Feed can work with full dynamics, even at long indexing progressions.

Request for a quote

RM2M

France

Electromagnets 200, 500 and 950 kg with permanent magnet for cold loads Self-contained battery model. Operating Modes: Manual: Simple use with buttons to activate or deactivate magnetization. Automatic: Quick activation and deactivation of magnet without manual order, ideal for hard-to-reach areas (no need to control with pendant button to take or release the load). Flexibility: Equipped with 3 power levels, they allow for sheet metal depiling. Benefits: Since it is a permanent magnet electromagnet, the battery is only used during demagnetizations, which gives it a long autonomy. There is no risk that the load falls because it is an electromagnet with permanent magnet. They are equipped with a force sensor that prevents the release of the load if the load is not put on the ground (which naturally prevents dropping).

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Application areas for straightening presses include the sheet metal processing industry. Here, this type of press is used for the straightening of semi-nished products, such as the levelling of uneven sheet metal and slab surfaces, which are used in subsequent processes. In addition to high straightening accuracy, Siempelkamp straightening presses provide a broad straightening spectrum and high exibility in the further processing of sheet metal. For materials with a tensile strength of 1,300 N/mm2, sheet metal with a thickness of approx. 300 mm can be processed To do so, the presses are equipped with one or several straightening rams which can be operated together or individually. The pressing force needed for straightening is applied across the entire press width. Sheet metal can be straightened by cold or warm forming with sheet temperatures of up to 600°C.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

TRIBUNAS & FIGUEIREDO, LDA

Portugal

We offer sheet metal bending services up to 3m. We have high-performance press brakes with 7 axes and up to 160 tons of bending force.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

EPP ENERGY PEAK POWER GMBH

Germany

This flat rate for the proven Alumero substructure for pitched roofs allows you to calculate your offers quickly and easily. Please note that the individual static calculation must be made by us at the latest when you place your order.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in sheet metal Fabrication & Stamping services more than 20 years,have been customized many kinds of sheet metal Casing,Enclosure,Bracket,Plate,Decoration Panel for different industries. We providing various processes such as punch Laser cutting,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Sheet Metal Fabrication Products Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishes: Anodize,painting,powder coating,blackening,electroplating of chrome/zinc/nickel /tin/silver... sales@mxmparts.com +86 13780014913

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

We offer cleanout set. Plumbing cleanout is a cleanout fitting with a removable plug that is found in a roughed-in waste system. It is designed to help keep clear any type of debris that could cause any type of stoppage in the water drain lines. Cleanout sets are usually placed at the connection point between the sewer lines and the drain lines where the base is located of a vertical stack, and at all places were the pipe direction changes at about 90 degrees. Material: Products are available in Stainless Steel AISI 304 (EN 1.4301) / AISI 316 (EN 1.4401 / 1.4404), Chrome plated Brass, Nickel Bronze Sizes: Currently sizes available are 200X200mm, 150X150mm 100X100mm, 80X80mm etc. Special sizes can be made as per your requirement.Finishes: Various finishes are available like MATT, MIRROR, and SATIN Fitment: It slips snugly into the drainage pipe and is easy to install. Cleanouts can be designed to fit various pipes. Designs: Various types of sizes and designs are available.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg is a China manufacturer specialize in sheet metal Stamping services more than 20 years,have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver...

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in Turning Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in sheet metal Stamping services more than 20 years,have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver...

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg is a processional sheet metal Stamping Parts manufacturer from China,have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver... sales@mxmparts.com WhatsApp:+86 13780014913

Request for a quote

CESAL ELEKTRO S.R.O.

Czech Rep.

We bend sheet metal up to and including 4 mm Maximum product length 3000mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CESAL ELEKTRO S.R.O.

Czech Rep.

The maximum sheet size we can process is 2000x1250mm Maximum sheet thickness 4mm

Request for a quote

CESAL ELEKTRO S.R.O.

Czech Rep.

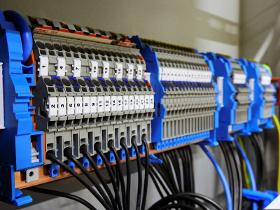

The offer of electrical installation work forms the solid foundation of our company. It is connected with the own production of electrical switchboards. high current and low current installation by installing a lightning rod design activity Production of LV switchgear (without limitation by current value)

Request for a quote

CESAL ELEKTRO S.R.O.

Czech Rep.

Allow us to briefly introduce ourselves and at the same time offer the services of our company. we precisely manufacture sheet metal parts, cabinets, covers and control cabinets made of steel, aluminum or copper sheet up to a thickness of 3 mm we treat the surface with powder paints, galvanizing we describe the screen printing method we weld or press bolts, nuts, screws onto sheet metal we have exact connector tools for 100% visual quality we make various moldings, signs (e.g. grounding) or bridges for attaching cables assembly, pre-assembly, packaging we have our own trucking company TIG, MAG and laser beam welding - we produce in small and large series

Request for a quote

CESAL ELEKTRO S.R.O.

Czech Rep.

With its compact dimensions and zero inside turning radius, the Genie® GS™ - 3246 scissor lift is ideal for indoor and outdoor construction, maintenance and installation on level ground and in confined spaces Max. working height 11.75 m Max. basket capacity 318 kg Drive type Battery Own weight 2800kg

Request for a quote

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom round cover part is made by material stainless steel, metal stamping, and machining in Taiwan which base on customer’s requirement and meet the ISO certification. Industry:Machinery Plating:Steel Product type:metal stamping parts Product size:as customer's required, dia.12.7*6 Material:as customer's required, stainless steel Material available:alloy steel, aluminum, as customer's required, brass, carbon steel, copper, stainless steel Tolerance:as customer's required, normally UNI-ISO 2768 Processing:metal stamping Surface treatment:Cr-plating, Ni-plating, Tin-plating, Zn-plating, as customer's required, copper-plating, powder coating Packing:as per customers' requirement, standard export carton with pallet Measurement:2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application:as customer's required

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

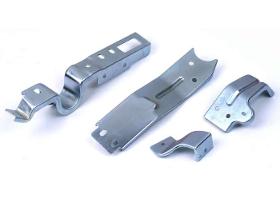

The custom part is made by material 304 stainless steel, metal stamping, and machining in Taiwan which base on customer’s requirement and meet the ISO certification. Industry:Machinery Plating:Steel Product type:metal stamping parts Product size:74.9*45*40 mm , as customer's required Material:stainless steel Material available:alloy steel, aluminum, as customer's required, brass, carbon steel, copper, stainless steel Tolerance:Normally UNI-ISO 2768, as customer's required Processing:metal stamping Surface treatment:Cr-plating, Ni-plating, Tin-plating, Zn-plating, as customer's required, copper-plating, powder coating Packing:as per customers' requirement, standard export carton with pallet Measurement:2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application:as per customers' requirement, tool holder

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom part is made by material 304 stainless steel, metal stamping, and machining in Taiwan which base on customer’s requirement and meet the ISO certification. Product type:metal stamping parts Product size:120*83*54 mm, as customer's required Material:stainless steel Material available:alloy steel, aluminum, as customer's required, brass, carbon steel, copper, stainless steel Tolerance:as customer's required, normally UNI-ISO 2768 Processing:metal stamping Surface treatment:Cr-plating, Ni-plating, Tin-plating, Zn-plating, as customer's required, copper-plating, powder coating Packing:as per customers' requirement, standard export carton with pallet Measurement:2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application:tool holder

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom part is made by material stainless steel, metal stamping, and machining in Taiwan which base on customer’s requirement and meet the ISO certification. Product type:metal stamping parts Product size:330*115*7 mm, as customer's required Material:as customer's required Material available:alloy steel, aluminum, brass, carbon steel, copper, stainless steel Tolerance:as customer's required Processing:metal stamping Surface treatment:Cr-plating, Ni-plating, Tin-plating, Zn-plating, as customer's required, copper-plating, powder coating Packing:as per customers' requirement, standard export carton with pallet Measurement:2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application:as customer's required

METALUX

North Macedonia

LASER CUTTING Our laser cutting services provides the ability to create custom parts out of a variety of materials. Our Fiber Laser Machines can cut almost anything you can draw, including sharp angles, smooth curves, small screw holes and complex trim patterns and lace designs. CNC PUNCHING All of our products are made using cnc punching machines. Which enable precision manufacturing. We offer this service also to third parties. BENDING We have multiple bending presses, which enables us to produce a large quantity of standardized parts and to offer quick turn around time for our clients. We can bend complicated shapes, different material thicknesses and types. WELDING We offer different type of precision welding. Like TIG, MIG and Spot welding. POWDER COATING Powder Coating gives consumers, businesses, and industries one of the most economical, longest lasting, and most color-durable quality finishes available on virtually any type of meta

Request for a quote

NEGOFILTRES

France

Perforated metal sheets Perforated metal sheets are available in panels of 1000 x 2000 mm orin manufactured pieces. Standard matter: SS 304, SS 316, Steel, Brass, Aluminum… Perforation standard of 0.5 to 20 mm, thickness of 0.5 mm to 5 mm. Uses: Industries, filtration, building, design and decoration…

Request for a quote

KEDY

Turkey

Introduce the K5200 Sheet Metal Tong & Sheet Lifter from KEDY. The ultimate solution for safe and efficient handling of large sheets of metal. With a maximum load capacity of 20 tons, it can easily handle even the heaviest sheets of metal. Equipped with remote control, it allows the operator to easily extend and retract the arms of the tong from a distance, making it a convenient and efficient tool for handling large sheets of metal. The sheet metal tong is also designed with safety in mind, it has an emergency stop button, programmable memory, auto-grip and overload protection, ensuring that the operator is always in control. It's compact, lightweight and easy to transport, making it ideal for worksites of all sizes. Upgrade your metal handling operation today with the K5200 sheet metal tong and sheet lifter from KEDY. Contact us today to place your order and experience the benefits of the K5200 sheet metal tong and sheet lifter for yourself!

Request for a quoteResults for

Levellers for sheet metal - Import exportNumber of results

45 ProductsCountries

Category

- Sheet metals - stamping (26)

- Sheet Metal & Tubes (7)

- Industrial sheet metal work (4)

- Metal straightening machines (3)

- Electrical & Electronic Components (1)

- Forming - steels and metals (1)

- Grids, metal (1)

- Laser - cutting and welding machines (1)

- Lifting equipment (1)

- Lifting equipment - accessories (1)