- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal forming

Results for

Metal forming - Import export

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 3,22 kg - 6,44 kg Height: 1,2 cm - 1,2 cm Width: 1,2 cm - 1,2 cm Material: 3 m - 6m

Request for a quote

PROSAW LIMITED

United Kingdom

ASM model is made of cast iron construction. ASM machines are combining the user friendly features, quality and best prices as an economical model. ASM - 3 Rolls Asymetical Plate Roll Machine Standard Details Body is made of cast iron construction Central rollers powered with electric motor, gearbox and gear drive Cone bending device Self brake main motor Upper roll is opanable by side Lower roll and back roll are with hand wheels up & down adjustable. Separate eletric control panel with foot pedal Suitable for CE, ISO 9001-2008, TSEK and TURQUM certificates ASM - 3 Rolls Asymetical Plate Roll Machine Optional Features Induction hardened rolls. Back roll with motor. Digital display.

Request for a quote

SIMPAC EUROPE GMBH

Germany

C-frame presses are flexible solutions for manual work as well as for automated production processes. The CS is the all-rounder among the C-frame presses, while the ECS is ideal for punching and cutting operations with a higher degree of automation. Overview: ● Press capacity: 350-3,000 kN ● Part size: small ● Slide kincematics: crank ● Application: cutting, stamping, bending, embossing Description and benefits: ● Compact design, no foundation work required, good accessibility for maintenance ● Solid, low-stress annealed press body in monobloc design with minimal frame deflection ● Durable, wear-resistant and very quiet hydraulic clutch ● Casting slide with vibration dampening properties (ECS series) ● 4-fold slide guiding for a high tilting rigidity ● Hydraulic overload protection ● Production time as of 12 weeks

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic HM 35 is the ideal hotformer for the costefficient production of precision forgings with a diameter of up to 75 mm, with a production rate of up to 170 parts per minute. Main advantages Highest productivity in this class, High process reliability, Controlled and lowimpact part discharge, Four forming stations for wide range of applications

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 509 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 108 mm, with a production rate of up to 100 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 509 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 108 mm, with a production rate of up to 100 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 30 S is the ideal hotformer for mediumsized forgings with a diameter of up to 67 mm, with a production rate of up to 140 parts per minute. Main advantages Reliable and durable design, Wide range of uses, Smooth part discharge, High process reliability thanks to servoinfeed and electronic bar end elimination device (ESA 600), Power Failure Protection for high machine safety even during power failures

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 20 S is the ideal hotformer for the costefficient production of high volumes of steel and brass parts with diameters of up to 38 or 42 mm, with a production rate of up to 200 parts per minute. Main advantages Compact design, Easy to operate, High productivity

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 20 N is the ideal hotformer for the costefficient production of forged cam lobes and other challenging forgings with a diameter of up to 48 mm, with a production rate of up to 200 parts per minute. Main advantages High productivity, Lowimpact part discharge, Precise 4roller servoinfeed for challenging parts, Easy to operate

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The COLDmatic CM 45eco is the ideal coldformer for accurate and complex parts from wire, with a production rate of up to 160 parts per minute. It boasts short commissioning times and has a compact design so it takes up less space. Main advantages Easy to operate, Separate lubricant and coolant circuit for maximum tool service life, Very high cutting quality, Accurate parts transport, Versatile kinematics, Optional equipment with heating system, Short commissioning times

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The COLDmatic CM 625 is the ideal coldformer for accurate and complex parts from wire, with a production rate of up to 180 parts per minute. It boasts maximum cutoff quality and userfriendly servo technology in the infeed and transfer unit. Main advantages Short retooling times thanks to innovative servo technology, Easy to operate, Separate lubricant and coolant circuit for maximum tool service life, Very high cutoff quality, Accurate servo linear infeed without bar stop, for defectfree cutoff surfaces, Accurate servo transfer unit for safe part transport, Versatile kinematics, Optional equipment with heating system

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The COLDmatic CM 725 is the ideal coldformer for accurate and complex parts from wire, with a production rate of up to 180 parts per minute. It boasts maximum cutoff quality and userfriendly servo technology in the infeed and transfer unit. Main advantages Short retooling times thanks to innovative servo technology, Easy to operate, Separate lubricant and coolant circuit for maximum tool service life, Very high cutoff quality, Accurate servo linear infeed without bar stop, for defectfree cutoff surfaces, Accurate servo transfer unit for safe part transport, Versatile kinematics, Optional equipment with heating system

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

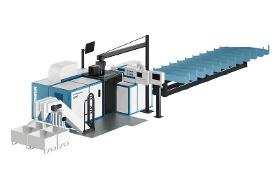

Our isothermal forging presses produce sophisticated, heavy-duty components for high-tech products. We furnish our customers with rst-class solutions including control systems for the ne-tuning of pressing speeds. Our presses are designed for high-precision applications indispensable in the aircraft/aerospace and medical engineering industries. The challenge here is to manage pressing speeds of 0.01 mm/s in controlled operation, which is ensured by our own electrical and hydraulic control engineering Siempelkamp also oers plants to be used for isothermal forging. They comprise the furnace, the feed manipulator, the forging press, the die heater, the hydraulic drive system and the entire automation technology. The plant control for isothermal forging presses monitors and documents the process parameters in compliance with the certication standards to be observed in the aircraft industry.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

As the leading provider of metal forming presses we are setting the standard worldwide. Our expertise in plant engineering and process technology is unique. This is because the individual performance features from the design to the startup of the equipment create a coherent and complete solution from a single source. Our hydraulic presses for metal forming are at home in cold and hot forming. From turbine disks for aircraft to pipeline pipes in the oil and gas industry to longitudinal beams in trucks: In our key industries of automotive, energy, rail and aerospace, we offer the right solution for every product. We supply not only the press, but also the associated process technology. Our range of services includes forging, thick sheet metal forming, raw forming, sheet metal forming and ring rolling. Our special systems for metal forming offer the perfect balance between the use of standard components and a custom-made design.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS quality now available for Swiss-type lathes. This new development in driven tools is EWS's response to many customers' requests. The tool systems may appear straightforward at first sight, but their simplicity belies their performance. The design concentrates on the mounting and the spindle concentricity. The requirement profile was developed jointly with an American medical technology company which uses very small drill bits and requires extreme concentricity properties. The spindle bearing technology used with labyrinth seals sets new standards in this field, and is associated with a long service life. Provision has already been made for service. The service centres in Germany, China, Korea and the USA have already been trained in the system and are ready to respond without delay. Third-party brands can also be serviced there at any time. Download catalogue: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS goes milling With its latest range of angular heads, EWS brings its trusted technology with new features to machining centres. The system range was presented to the public for the first time at EMO 2015. An elegant design houses high-performance technology, or to put it simply Precision meets Motion. Advantages: the smart solution for compensating for there not being a machining axis Machining hard-to-reach parts Centre boring stepless angle adjustment around the horizontal axis, with tangentially acting double cone clamp MR > 250 Nm Prerequisite: The prerequisite is a "stop block" on the machine. This prevents the entire unit from turning while simultaneously defining the position of the angel of rotation. Variations: basic duplex offset Request form: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

High-speed thread cutting with reversing kinematics The new EWS Tapmatic thread cutting head for driven tools enables thread cutting processes without having to reverse the direction of rotation thanks to its reversing kinematics. This saves time and energy and protects the motor – all this with a defined depth of thread. The units are available for M3-M12 threads.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Emulsion can do more than just cool... At least when using EWS Spinjet, the coolant is used to drive a turbine which allows the tool to rotate to up to 50,000 rpm, depending on the type. The turret's tool drive stops moving during this process! See the attached flyer for the technical requirements and details. Download Manual: PDF

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Trifix® is the new adjusting system for Gildemeister multi tasking machines. The double sided adjusting system is guided by a very precise key way at the surface of the turret. The plates are preloaded, and the resiliency in the adjusting system eliminates static redundancy. This allow the exact position of the tool to be secured and significantly reduces the setup time of the machine. Because this is a highly sophisticated precision instrument it is not possible to use double serrated tool shafts. The tool is supplied fully adjusted and can be used right away. EWS is the DMG system partner for this tool generation. Trifix® advantages: Repeat accuracy below 6 µm at radius of 200 mm High positioning accuracy from one station to another (0.01 mm) Driven tools and static tool holders are completely aligned Static tool holders can be used together with additional drill pattern for mounting Heavy duty spindle noses can be used together with additional d

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Mount tools safely and in the correct position while remaining flexible, all this is possible with the UMB100 mounting unit. The tool clamping units can be changed quickly, making the system an ideal mounting aid for multi-tasking machines. It only takes a few seconds to replace an adapter. The unit with snap-in swivel can be pivoted 4 x 90° at the touch of a button so that even angled holders can always be mounted in the ideal position. Universal mounting block UMB100 Tool holder for VDI holding fixtures Tool holder for Varia VX Tool holder for steep-angle taper holding fixtures

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Keyway broaching on lathes is a common thing. What is new is to speed up this operation with low stress for the machine! Slot is driven by the tool turret of the machine, with the input rotary motion being converted to a translation with superimposed lift-off function. This makes programming extremely easy. The keyway broaching unit is positioned in the prepared bore – in such a way as to make the extended tappet oriented to the end position in the Z axis. The depth of the slot is produced by a constant X-feed moving between 0.04-0.08 mm/stroke. The speed of the spindle ranges between 400 R/min – 1,000 R/min, with one rotation corresponding to a complete stroke. This way, for instance, a feather key groove with a width of 6 mm and a depth of 5 mm is produced within 7.5 sec. (800 R/min and 0.05 mm feed/rotation). With this operation it is important that the chip can break at the end of the groove, that is that a cut-in or a bore exists.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Reaching concentricity 0 using a simple collet chuck and this within one minute: this is Zero-Zero. The specifically designed clamping nut with 6 symmetrically arranged screws at the circumference makes this step possible. The clamping nut is split, so that the inner ring can be minimally shifted. This simple technical finesse allows to eliminate tolerance additions. The machine operator only has to replace the previous clamping nut, which step opens up a new concentricity dimension – and this for a price starting at € 90.00. Zero-Zero is available for DIN 6499 collet chuck holders from ER 16-ER40.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

The new EWS tcJet range Optimal chip transport thanks to EWS tcJet EWS tcJet transports the coolant through the inset directly to the cutter and guarantees optimal chip transport... At the same time, the cutting edges have a significantly longer service life. EWS's interior cooling version is available for normal and high-pressure applications for various tool holder fixtures and cutting insert manufacturers.

Request for a quoteResults for

Metal forming - Import exportNumber of results

523 ProductsCountries

Company type

Category

- Steels and metals - forming and cutting (281)

- Forming - steels and metals (80)

- Milling - machine tools (21)

- Sheet metals - stamping (16)

- Thermoforming, plastics - machinery (14)

- Metal industrial presses (8)

- Metallurgy - machinery and installations (7)

- Industrial sheet metal work (5)

- Hot forming (4)

- Industrial cutting machine tools (4)

- Lubricants, industrial (4)

- Bending - steels and metals (3)

- Chemical catalysts (3)

- Cutting - steels and metals (3)

- Screws (3)

- Ceramics, industrial (2)

- Metalworking - portable power tools (2)

- Pipe and tube fittings - ferrous metal (2)

- Rolling machines (2)

- Safety equipment, work (2)