- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal processing machines

Results for

Metal processing machines - Import export

ZS INDUSTRIES CO., LTD

China

Material: Steel: carbon steel, stainless steel, alloy steel Non-ferrous metals: Alu, brass Plastic Process: Machining/stamping/welding Surface treatment Assembly Testing Application: Agricultural & farm machinery Animal feeding device

Request for a quoteFAUDI GMBH

Germany

Advantages High flow rate No back flushing during the regeneration Easy discharge of the filter cake Short regeneration time Possible use of various filter belts Cleaning station for filter belts New, extremely pressure-stable design Area of application Pressure Belt Filters are used for the filtration of coolants in metal machining processes, preferable grinding sludges from rough-machining. Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid without Filtration degree 30-100 µm Medium oil and emulsion Filter material filter belt

Request for a quote

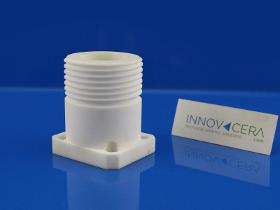

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

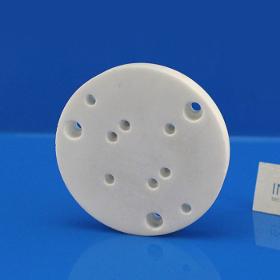

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

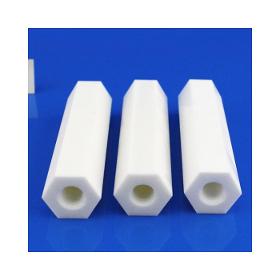

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Electrical Insulation Macor Rod: Machinable Glass Ceramic has a continuous use temperature of 800oC and a peak temperature of 1000oC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed,ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant. Macor Rod for Heating Element Features: 1.High Dielectric Strength, Excellent Insulation 2.Good Machinability, Machinable With Ordinary Metal Tools And Fast Turnaround 3.High Precision, Hold High Tolerance 4.Excellent Acid And Alkali Resistance 5.No Outgasing And Zero Porosity 6.Withstand High Temperature Up To 800℃ Machinable Glass Ceramic Rod Applications 1.high strength and high tenacity product, magnetic material, piezoelectric ceramic, dielectric ceramics

Request for a quote

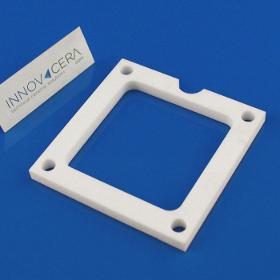

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic Square Ring: Machinable Glass Ceramic has a continuous use temperature of 800oC and a peak temperature of 1000oC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed,ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant. Macor Ceramic Square Ring Features: 1.High Dielectric Strength, Excellent Insulation 2.Good Machinability, Machinable With Ordinary Metal Tools And Fast Turnaround 3.High Precision, Hold High Tolerance 4.Excellent Acid And Alkali Resistance 5.No Outgasing And Zero Porosity 6.Withstand High Temperature Up To 800℃ Machinable Glass Ceramic Square Ring Applications: 1.high strength and high tenacity product, magnetic material, piezoelectric ceramic, dielectric ceramics

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

CNC Metal Processing by CNC machining centre Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

CRAEMER GMBH

Germany

The CR1 Euro pallet is optionally available with or without reinforcement profiles. With profiles, it is the perfect solution for complex tasks and therefore firmly established as multi-use pallet, especially in pooling. The sturdy CR1 heavy-duty pallet has proven its worth in internal logistics processes of numerous industries, including automation, metal processing, machine construction and tool making. Without steel profiles, the CR1 is ideal for applications where the extreme load-bearing capacity of the metal-reinforced version is not needed. Characteristics: Available with 3 runners Very high load-bearing capacity Dimensionally stable with first-class bending parameters, ideal for roller conveyors and automated high rack warehouses Chamfered edges on both sides of all runners Palgrip® anti-slip strips on the top deck Options: Corrosion-protected reinforcement profiles, for a load-bearing capacity of up to 1,750kg in high rack Rims: without, 7mm RFID transponder

Request for a quote

FRIGORTEC GMBH

Germany

The POWDRYER™ PD08 metal powder dryer is used to dry inorganic metal powder for the complex additive manufacturing (3D printing) process. It corrects the manufacturer’s fluctuating metal powder qualities, thus optimizing the metal powder’s flowability. It also reduces the number of air inclusions in finished workpieces. Significantly higher material densities are the result. Fields of application > Particularly for metal printing products where maximum strength is required > For the printing of alloys of aluminium, titanium, tool steel, etc. > Special tools for the metal-processing industry, machine and system engineering, prototype development, and more > Aviation, aerospace, and automotive industries, plus medical and dental technology

Request for a quote

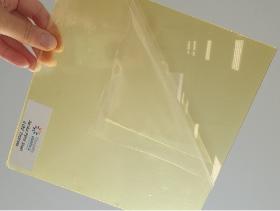

WESTLAKE PLASTICS EUROPE

France

An innovative techno-material combination for aero / defense / rail parts: With a resin manufacturing partner, Arkema, we have succeeded in extruding sheets in an amorphous state (PEKK material already qualified for aerospace) which crystallizes during thermoforming. The fact that the plates are amorphous allows thermoforming deformation and then crystallization offers all the thermal / mechanical / chemical properties of an ultra high performance polymer. Value proposition: advance in the replacement of metal parts / reduce process costs for machined PEEK parts / open the door to the manufacture of large parts (aircraft interior, drones, defense systems, railways, electrical boxes, ducting systems, etc. )

Request for a quote

MARXAM PROJECT

Poland

Turning services and milling services are one of the basic methods of machining metal and plastic elements. A park of conventional machines maintained in the highest accuracy class allows for the precision machining service – production of precise details in high tolerance classes for both larger and smaller production series. Machining of metal materials, metal alloys or plastics is the basic method of metal processing classified as subtractive machining, which allows to obtain structural elements of specific shapes and number of details. Conventional metal turning and conventional plate milling are fundamental methods of machining – Marxam Project encourages you to use the service of professional shaping of materials, which is carried out using high-class equipment in a modern machine park. Our lathe services allow for machining plates, metal sheets, milling steel plates and many more.

Request for a quote

MR CO. LTD.

Ukraine

Milling is the process of machining metal with a specific cutting tool, a milling cutter. The milling cutter removes excess material from the workpiece to produce an element of a given shape. Unlike turning, in milling, the workpiece moves forward while the milling cutter rotates. By milling processing, you can obtain a part with a complex shape and geometry from a workpiece. The milling machine is primarily used for demanding tasks such as gear cutting. Our machining workshop is equipped with the most advanced high-tech CNC equipment. We offer our customers full-cycle material processing services, from designing to the protective coating.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNITEDPARTS SUPPLIES CO., LTD.

Taiwan R.O.C.

The custom part is made by material carbon steel, metal stamping, machining, yellow zinc-plating, and assembly all the parts in Taiwan which base on customer’s requirements and meet the ISO certification. Product type: metal stamping Product size: 100*40*45 mm, as customer’s required Material: carbon steel Material available: alloy steel, aluminum, brass, carbon steel, copper, stainless steel, as customer’s required Tolerance: normally UNI-ISO 2768, as customer’s required Processing: metal stamping, machining, yellow zinc-plating, assembly Surface treatment: Cr-plating, Ni-plating, Tin-plating, Zn-plating, copper-plating, powder coating, as customer’s required Packing: as per customers’ requirement Measurement: 2.5D Projecting apparatus, Altimeter, Calipers, Coating thickness tester Application: as customer’s required

EHRT MASCHINENBAU GMBH

Germany

EHRT's standard bending machine EB 40 is distinguished by their extreme robustness and simple handling. The machine is modulary and flexibly structured, so that each machine can be individually adapted to the customers’ needs. EHRT bending machines can perform a multitude of bending modes. Offset bending, flat bending, edge bending, torsion bending, closed shapes and U-bends are some examples. The hydraulic cylinder of the bending machine is fitted with a force of 344 kN. The machine offers an outstanding bending accuracy of 0.2°. A special plug-in system makes tool changing very user-friendly on the EHRT machines. This guarantees very fast setup times and yet robust and precise bending tools. Beckhoff's PLC machine control enables machine maintenance and software updates via remote access.

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

Angular contact bearings are designed so that the contact angle between the raceways and the balls is formed while the bearing is in use. The ability of angular contact ball bearings to withstand axial loads increases proportionally as the contact angle increases. Features of angular contact ball bearings: high stiffness ideal for high-precision performance at high speed able to withstand heavy axial loads and moderate radial loads available with a single or double row, in the open or shielded / sealed versions Series Single row: 7200, 7300 Double row: 3200, 3300, 5200, 5300 APPLICATIONS: Agricultural Machinery Metal processing Oil Industry Paper making machines Wind sector Gearboxes Pumps and Compressors Ventilators /Fans Semiconductors Motorcycle Industry Machine tools Electromechanics Textile machinery Injection molding machines

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

"With the help of our rich machine park and well-experienced engineers, we can answer your custom design machine part needs. Please don't hesitate to ask for the price."

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Aluminum Alloy Parts by Precision CNC Machining Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

High precision steel shaft/splined shaft for connecting/coupling shafts 1) Customer’s drawing or samples accepted. 2) Excellent and high quality control. 3) Prompt delivery. 4) Competitive price. steel shafts 1) Material: Carbon steel , Stainless steel,brass or as per customer’s requirements. 2) Diameter: 0.3-80mm, tolerance:+/-0.005mm. 3) Roundness: 0.003mm. 4) Roughness: Ra0.04. 5) Straightness: 0.005mm. 6) Hardness: HRC/HV. 7) Precision: Grade 6. 8) Length: Max.700mm. 9) Heat treatment:Point hardening,quenching hardening. 10) Surface treatment: zinc plating, nigrescence,chrome plating, nickel plating etc. 11) OEM Service: Providing us the drawing with detail information. 12) Offering products with speciality, quality and efficiency. 13)Package:Plastic bag inside and outer standard carton , pallet.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Machining Parts ● Materials for CNC Precision machining parts We can process product materials are: An aluminum alloy series: all aluminum and aluminum alloy (ASTM Grade from1050-7475), commonly used are: 2011,5052,6061,7075, etc. (2) Copper Alloy Series: all copper and copper alloy, copper, copper, brass, bronze, phosphor (the ASTM grades from C11000 to C38000), commonly used: C11000, C22000, C26000 (3) Stainless Steel Series: all the basic machining stainless steel, the ASTM grades(JIS grade corresponds to the basic, together with the SUS can):201,301,303,304,314,316,420,430,630 Steel series: all the basic machining steel can be processed, for example: 20 # steel, 45 steel, easy to cut iron (common SUM24L, SUM22, Y12, Y15) ● CNC Precision machining parts accuracy Machining accuracy: IT6 level, such as the 10mm dimensions, tolerances can be done 0.009mm, 20mm size tolerances can be 0.013mm ● Maximum size of Precision parts suit to CNC machining

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Metal Shaft Motor shaft, Fan shaft, Precision shaft, Micro Shaft, Rotor shaft, Pump shaft, Pins, Hinge pin, Metal part, Mechanical precision part. Mechanical precision part/Mechanical precision part. 1) Material: Carbon steel, Stainless steel, brass or as per customer’s requirements. 2) Roundness: 0.001mm 3) Roughness: Ra0.04 4) Straightness: 0.001mm 5) Length: Max. 1000mm 6) Heat treatment: Point hardening, quenching hardening 7) Surface treatment: Zinc plating, nigrescence, chrome plating, nickel plating etc. 8) OEM Service: Providing us the drawing with detail information. 9) Offering products with speciality, quality and efficiency. 10) Package: Plastic bag inside and outer standard carton, pallet. According to client’s demand. Specifications for CNC METAL SHAFT

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Description: •Precision machined components, Machining service, CNC precision machining, Stainless steel precision machined parts manufacturer •Material to process: aluminum, stainless steel, carbon steel, brass •Precision: 0.010-0.002mm •Equipments: CNC lathe, processing center, miller, cylindrical bore grinder, surface form grinder, punching machine, etc. •Surface treatment: zinc, nickel, anodized, polishing •Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. •We are able to supply Precision machined components, mechanical parts machining, surface treatment such as anodize and plating according to our customers’ requirement. •Packaging details: inner plastic bag, outer standard carton box •Delivery time: 25-35 days Notes: we manufacture precision machined components in compliance with customer’s designs. The products are shown here ony to present the

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

Machine Technical Specifications Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Boiler: Our machine features a double-walled stainless steel boiler. Cooling System Vacuum System Maximum Safety Automatic Recipe System Grinding and Mixing Capability Boiler Plates: The boiler plates are entirely made of 304 quality CrNi material. Boiler Body Plate Thickness: 4 mm Rear Dome Plate Thickness: 4 mm ETDSK Mixer Gearbox: 80 RPM 2.2 KW Electrical Components: Utilizing SCHNIDER or DELTA electrical components. Ensures thorough blending of added spices. Ensures optimal binding of added proteins. Prepares the product for further processing.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

MACHINE TECHNICAL SPECIFICATIONS Chassis Material: Entire chassis crafted from 304 CrNi material. Boiler: Equipped with a double-walled stainless steel boiler. Cooling System Vacuum System Maximum Safety Automatic Recipe System Grinding and Mixing Capability Boiler Plates: Made entirely from 304 quality CrNi material. Boiler Body Plate Thickness: 4 mm Rear Dome Plate Thickness: 4 mm ETDSK Mixer Gearbox: 80 RPM 2.2 KW Electrical Components: Utilizing SCHNIDER or DELTA components. Ensures thorough blending of added spices. Facilitates optimal binding of added proteins. Prepares the product for processing Warranty: The ETDSK Vertical Meat Drum is covered by a 2-year warranty. Chassis and boiler construction are guaranteed for 2 years. Electrical components are covered for 1 year under the manufacturers' warranty Benefits: Enhances spice blending for better flavor. Improves protein binding for texture.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

MACHINE TECHNICAL SPECIFICATIONS - Manual Ease of Use - Up to 50 Cm Diameter Suitable for Carrying Rotors - It has a carrying capacity of up to 250 KG. - Horizontal and Vertical Rotary Transportation Option. - Machine Dimensions : - Width : 100 cm - Height : 135 cm - Height : 200 cm - WARRANTY : - Rotary Lift that we manufacture; (within production and fabrication defects) - Chassis and boiler manufacturing is under our 2-year warranty. - Electrical switchgear materials are under the guarantee of companies for 1 year

Request for a quoteResults for

Metal processing machines - Import exportNumber of results

54 ProductsCountries

Company type

Category

- Steels and metals - machining (17)

- Machine tools, metal machining - parts and accessories (16)

- Machine tools - metal machining (14)

- Ceramics, industrial (5)

- Meat processing machines (3)

- Ceramics, refractory (2)

- Milling - steels and metals (2)

- Punching machine tools (2)

- Aerospace and aeronautics - construction (1)

- Assemblies, hydraulic (1)

- Bearings - ball, needle and roller (1)

- Bending machine tools (1)

- Cutting - steels and metals (1)

- Freeze drying - machinery and equipment (1)

- Import-export - mechanical engineering (1)

- Machine tools - metal shaping (1)

- Metals - Machines & Equipment (1)

- Milk (1)

- Pallets (1)

- Perforation of steels and metals (1)