- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mim injection moulding

Results for

Mim injection moulding - Import export

PLANSEE SE

Austria

Plansee charge carreiers from refractory metals are dimensionally stable at high temperatures and in contrast to graphite parts they are also suited for high-vacuum furnaces. MLR with its superior creep resistance and retained ductility after high temperature operations is the ideal material for mechanically loaded furnace parts. Plansee designs and fabricates furnace fixtures to customer specifications, e.g. for aeronautics, glass industry, Metal Injection Molding (MIM), commercial heat treatment and various other thermal processes. Alongside molybdenum and tungsten, we primarily manufacture our charge equipment from TZM and ML. The creep resistance of these alloys is ten times better than that of pure molybdenum and they are also exceptionally ductile. As a result, our charge systems are perfectly equipped to cope with frequent changes between high and low temperatures.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Since the 1980’s, we have been a leading producer of superfine powders for Metal Injection Molding (MIM). Our expertise and advanced atomization technology enable us to produce very fine MIM powders down to 10µm. Products and Sizes Our MIM water atomization technology is compatible with most conventional high-performance stainless steels and alloys. Special size distributions are available as well as some standard sizes. Grades: 17-4PH®, 70/30 Fe/Cr, 430L, 316L, other 300 Stainless Steel series Sizes: Typically smaller than 20µm Austenitic Stainless Steels 316L used in MIM applications which require good corrosion resistance, strength and ductility. Also available 304L and 310L. Ferritic Stainless Steels 430L ferritic stainless steel combines good magnetic response and some corrosion resistance. Also available 409L, 410L, and 434L.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK has the metallurgical expertise to produce specialty powders for super-niche and highly engineered applications. Our experience has made us a global leader in the field. Customized and Specialty Alloys Utilizing high pressure water atomization under carefully controlled conditions, we develop innovative powders in an extensive range of standard and custom alloys. Niche Applications Our high alloy powders are used in specialty segments including Sintered Metal Filters, Fiber – polyester and nylon production, Plastic Compounding, Hardfacing and Surface Coating, Powder Metallurgy (P/M), and Metal Injection Molding (MIM). Typical alloys include

Request for a quote

BILSA SAVUNMA TEKNOLOJILERI A.S.

Turkey

Metal Injection Molding can produce complicated and challenging parts in high quantities concerning their precision and fineness, and it offers several advantages over other manufacturing methods. -High surface quality -Reduced production time -Mechanical properties superior to castings -Ability to meet narrow dimension tolerances -High density -Mass production -Net-shape manufacturing with minimal material waste MIM eliminates the limitations and long efforts in standard production methods. It is a superior production method with other advanced applications, and also an advantageous option at a low cost.

Request for a quote

NOVELTY STEEL

Turkey

The mold comprises two main parts: the injection mold (A plate) and the ejector mold (B plate), which are also known as moulder and mouldmaker. Plastic resin is introduced into the mold via a sprue or gate in the injection mold. The sprue bushing seals tightly against the nozzle of the injection barrel of the molding machine, allowing molten plastic to flow from the barrel into the mold, known as the cavity. The sprue bushing guides the molten plastic into the cavity impressions through channels on the A and B plates. These channels, called runners, enable the plastic to flow along them. The molten plastic moves through the runner and enters specialized gates, ultimately filling the cavity geometry to create the desired part.

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

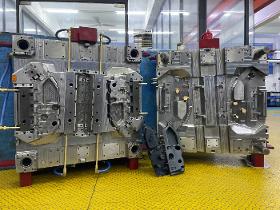

ACKOR MOULD LIMITED

China

Your relaible partner from China for injection molds & moulding parts with high- quality and cost-effective solutions, ISO 9001:2015 & IATF 16949 accredited

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in custom plastic molded parts by plastic injection molding more than 15 years, our factory is from Ningbo China, we can custom all kinds of plastic molded parts,steel pins inserted plastic parts. We have a variety of injection molding machines, large injection molding machines and small injection molding machines, vertical injection molding machines and horizontal injection molding machines, according to the type and structure of plastic components to choose the most suitable machine to produce, thus saving production and improving production efficiency and quality assurance. Plastic parts is very simple & popular in all industries, such as plastic cover, plastic knob,plastic bracket,plastic flange,plastic valves,plastic gears,plastic bushing,plastic base,plastic shafts,plastic mountings, plastic coupling,plastic fabrications,etc. Plastic injection molding is suit to complicated plastic parts with complex profile or structure, welcome contact us for quoting!

Request for a quote

HODA, UAB

Lithuania

HODA, UAB privately owned Lithuanian capital company, one of the biggest plastic injection moulders in Baltic states with 3400 m² area of production plant and 3500 m² of warehousing facilities. At the moment company operates 53 injection moulding machines, which gives us flexibility to produce different size and purpose plastic parts from a fraction of gram up to six kilograms of mass.

Request for a quote

HODA, UAB

Lithuania

At the moment HODA, UAB operates 54 injection moulding machines, which gives us flexibility to produce different size and purpose plastic parts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MATRIZ JUBILANTE UNIPESSOAL, LDA

Portugal

Moulds - bottles for packaging industry, detergents, pharmaceutical

Request for a quote

MATRIZ JUBILANTE UNIPESSOAL, LDA

Portugal

Molding service provides high accuracy and consistency - injection moulding manufacturer/ supplier.

Request for a quote

PLASTEMA SP. Z O.O. SP.K.

Poland

Our injection department is also involved in injection molds testing. We test injection molds for tool shops and customers who import molds, e.g. from China. In addition to tool testing, we also assess the quality of workmanship, check the compliance of the construction documentation with the actual state and possible modifications to the forms.

Request for a quote

PLASTEMA SP. Z O.O. SP.K.

Poland

We design and manufacture injection molds. Our design department manufactures about 50-60 injection molds every year - only for its own needs. We design cold-runner, hot-runner, one-component and multi-component tools.

Request for a quote

PLASTEMA SP. Z O.O. SP.K.

Poland

Many years of our technologists' experience in the field of projects implementation and development of technologies allow us to help with our customers' obstacles. We can deal with: - technology development in injection molding plants, - we help in the preparation of a business plan and commissioning of entire production plants or injection department in plants that have previously outsourced production to an external injection molding company.

Request for a quote

PLASTEMA SP. Z O.O. SP.K.

Poland

We make 50-60 injection molds up to 1500 kg every year. Our own design office take care of the whole tool implementation and its complete documentation. We manufacture single and multi-component tools depending on our customers requirements. We have experience in the construction of gas molds as well. Feel free to learn more about us visiting our website - www.plastema.pl

Request for a quote

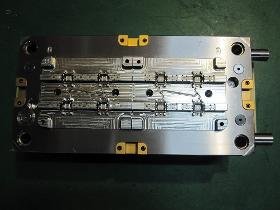

BESTONE TECHNOLOGY LIMITED.

China

Precision injection tooling-1 cavity side and 3 core side-this is core side-2.

Request for a quote

GPMFG

Canada

Plastic Injection Molding GPMFG is well-prepared to provide sizable amounts of injection molding parts promptly. In-house molds Development and Machining capability,32 injection molding machines from 50 to 800 tons. Products/Parts Analysis And Optimizing Tooling/Molds Development & Manufacturing Normal Injection Molding Insert Molding Overmolding 2K/2-Shot Injection Molding 3K/3-Shot Injection Molding Diverse Post Processes Available As a top China-based injection molding company, GPMFG specializes in premium plastic products for global clients. Our all-inclusive services cater to diverse material and color needs. State-of-the-art machinery enables small to large scale production. Clamping forces from 50-800 tons allow up to 24 cavities. Shot sizes from 3-600 ounces create finished items from 4 grams to 24 lbs. Complementary services include mold making, plastic finishing, and assembly.

Request for a quote

BESTONE TECHNOLOGY LIMITED.

China

Precision injection tooling-1 cavity side and 3 core side-this is core side-3.

Request for a quote

TOPWORKS

China

We Cover The Following Industries Computer/Business Equipment; Industrial; Packaging – Food/Beverage; Construction; Lawn & Garden; Machinery; Consumer Appliance; Electronics/Electrical; Agricultural; Household Utility Ware Medical/Laboratory What We Supply Plastics Design; Rapid Prototyping; Multi-cavity Plastic Mold; Family Plastic Mold; Hot-runner Plastic Mold; Plastic Molding (Injection and Blow); Secondary Operations; Assembly;

Request for a quote

GRUP HS MAKINE KALIP SAN. VE TIC. LTD. STI.

Turkey

The knowledge of design plastic injection mould is not enought, it is also important that the knowledge of operating plastic injection machine and polymer characteristics. Parameters used in injection machine are material injection temperature, injection pressure, speed, press time and push up feature. Designing injection mould with the knowledge of these characteristic provide both clients and us optimized mould manufacturing. Thanks to the plastic injection machine, founded in company structure, we are aware of following parameters. Our 30 years experienced staff can predict potential mistakes and we warrant trouble free and long duration mould manufacturing. We are assertive on low-cost and high piece injection capacity because of studying in design of modular calculation and flow diagram. Shrinkage of different materials are calculated with the 3D drawing programs by mechanical engineers of our company.

Request for a quote

MILES PLATTS

United Kingdom

Our standard coil bobbins, coil formers, insulation covers, housings, clips, terminals and toroid mounts are available in a comprehensive selection of imperial / inch and metric sizes to suit a combination of uses. Where required, we also have the knowledge, capability and flexibility to design and manufacture brand new, custom products. Here, we work closely with customers as a trusted partner throughout every stage of the development process. Standard products include - Coil Bobbins for UK Format Laminations Coil Bobbins for USA Format Laminations Coil Bobbins for Metric Format Laminations Coil Bobbins for Encapsulation Toroid Mounts AMCC Bobbins Gas Ignition Terminals Clips & Accessories

Request for a quoteResults for

Mim injection moulding - Import exportNumber of results

30 ProductsCountries

Category

- Injection moulding of rubber and plastic (6)

- Plastics moulding (5)

- Injection, plastics - machinery (3)

- Plastic products for engineering (3)

- Testing equipment (3)

- Metal powders (2)

- Packing and packaging - machinery and equipment (2)

- Die casting moulds (1)

- Finished Metal Products (1)

- Industrial furnaces (1)

- Sintering - steels and metals (1)