- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mixers for the beverages industry

Results for

Mixers for the beverages industry - Import export

OKSUZOGULLARI HORECA VE EV GERECLERI A.S

Turkey

Made of 304 chrome 18/10 stainless steel. Its body and strainer are stainless steel. It provides long-term deterioration of tea flavor. Provides suitable use for mass consumption. It is hygienic and long-lasting. It is economical with its automatic heat control system. Water heating system has been specially designed. Provides tea brew and hot water that does not stale throughout the day. It is equipped with a rust-free shock tube resistance that boils water. Provides ergonomic use with special model taps.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

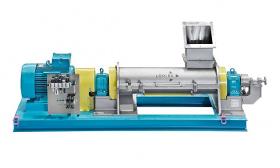

The continuous ploughshare mixer uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. The mixing elements having a defined shape and a special arrangement on the shaft, they ensure not only a reliable product conveyance but also a sufficient back-mixing of the product. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. The continuous process can be run at filling levels between 20 % and 50 % without influencing the mixing quality. Choppers can be additionally installed in the mixing drum.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The application range includes everything from processing of viscous components to paste-like products with poor flow. The range of food applications is exceptionally broad and there are also various applications for the pharmaceutical industry. The conical shape permits thorough residue-free discharge. The wet mixer system is a vertical mixing system for batch processes. The geometry of the conical or cylindrical mixing vessel, the arrangement and shape of the tools and their peripheral speed are adapted to each other in all sizes, resulting in effective mixing of all components. Depending on the process engineering tasks, the individual mixing tools are combined to form one tool both for material transport and for dispersion and disagglomeration processes. The installation height in the vessel is adjustable within a wide range. An adjustable deflector can be used to affect the product movement in a systematic fashion.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The ploughshare mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels on the mixing shaft in a horizontal, cylindrical drum rotate to the wall. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. Thanks to their form adapted to individual application and the speed adjustment, Lödige ploughshare mixers can be used for a wide range of applications. Choppers can be additionally installed in the mixing drum to increase the turbulence in the mixing process. This ensures the mixing of fine particles in small quantity and enables the dispersion of these products .

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The CoriMix® is a high-speed, continuous mixer for high throughputs, especially developed for homogeneous mixing of liquid and pasty components into dry substances. The system is based on the high peripheral speed of the mixing shaft tools of up to 50 m/s. The product is moved through the mixing chamber in a plug-flow manner. The retention time is extremely short compared with a continuous ploughshare mixer. The mixing chamber is divided into zones with different mixing tools enabling different shear intensity by selecting and adjusting the mixing tools according to each application. Liquid components are introduced directly into the product ring layer – either via tangentially placed liquid pipes through the drum wall or via a hollow mixing shaft with specially perforated tools. However, moistening of the mixer wall and shaft is largely prevented. The liquid distribution is similar to a nozzle but avoiding any risk of clogging or disturbance of the spray.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MIXACO MASCHINENBAU

Germany

The Robust Workhorse: The high-performance MIXACO universal mixer is ideal for many different applications. Whether slow, gentle homogenization or thorough mixing is required, consistently high quality is guaranteed for every mixing process. In particular, the universal mixer’s highly flexible design possibilities enable it to be adapted easily to suit the required mixing task and individual on-site requirements. The MIXACO universal mixer is available in sizes from 20 to 6,000 liters. All Benefits at a Glance •Can be used for a wide variety of applications, such as homogenization, dispersion, coating or granulation •Mixer tools optimized for the individual mixing task •Performance-optimized selection of mixing drives ensures high energy efficiency •Rapid cleaning possible when pivoting mixer lid is open •Double-walled mixing vessel enables ideal temperature control of product during mixing •ATEX version possible

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Container Mixer Vortex™ It is suitable for any industry where different recipes need to be mixed in quick succession, resulting in frequent mixer cleaning. As the transport container and mixer head are separate units, products can be conveyed to the next processing station without loss of time. The design of the MIXACO Vortex™ mixer, which was robust from the outset, is continuously being improved and updated. The system and its individual components are also configured for multi-level operation, with corresponding connectors to allow dust-free, airtight discharging of the transport container directly into extrusion, kneading, weighing and bagging machines. The MIXACO Vortex™ is more than simply a classic among container mixers; it also offers modern technology with numerous advantages for your in-house material logistics and work processes.

Request for a quote

GEO TEKNO LTD. CO.

Turkey

Suitable for Every Need Whether 500 liters or 50 tons, from the smallest capacities to the highest mixing speeds, mobile, fixed, vertical, horizontal, industrial, hygienic, stainless or carbon steel, GEO’s tailor-made, special design mixers are ideal for all kinds of mixing operations. GEO, with its expert staff and strong database, helps its customers to choose the most suitable mixer solution to use in their processes with detailed analysis. For renewal of existing mixer tanks or potential purchasings of new mixer tanks, do not order tanks without getting a quotation from us.

Request for a quote

ATILIM MAKINA

Turkey

Reactor, storage tanks, silos, reactors, blenders, mixers, mixer blades, turnkey resins and chemical plants, filters, heat exchangers, boilers, basketmill, basket mills, paint finishes, polyester plants, bio diesel plants, thin film evaporator, alkyd plant , Pva plant, styrene acrylic plant, mixer blades, storage tanks, plasticizers plant (DOP, DOTP, DOA, DINP, DIDP, TOTM), urea formaldehyde plant, autoclave, bunker, boiler washing machine,water solvent based paint factory,Pilot production plant, pilot reactor, pilot blender, pilot mixer mixer, pilot exchanger, pilot PVA, pilot alkyd plant, pilot plastic plant, pilot polyester plant, pilot bio diesel plant, pilot urea formaldehyde plant, pilot DOP, pilot DOTP, pilot DOA, pilot DIDP, pilot TOTM facility,universal pilot production plant,rashing Ring,Scrubber,Solvent based thermoset acrylic resin plant,Pipe heat exchanger,Chemical reactors,Reactor manufacturers,Companies manufacturing reactors,paste press machine turbo mixer,hot melt glue

Request for a quote

LETS PACK

Russia

Straight paper straw, individually wrapped in paper, great for a variety of drinks. Any color, any size, any diameter. Biodegradable & compostable. Best composition, Less than 2% glue. Hard enough. No human touch. Quality control. No fizziness. Suitable for product with lactobacteria. Doesn`t dry lips.

Request for a quote

TAMPOPRINT GMBH

Germany

For over 30 years TAMPOPRINT GmbH has been an established partner of the beverage and closure caps manufacturing sector and their suppliers. Today our high know-how distinguishes us and makes it possible to supply you with decorating and marking solutions with our rotary pad printing and laser marking technology. Our pad printing and laser automations meet highest quality requirements for the applications in multi-shift operations with high throughput speeds. As an expert for special solutions our project planning can draw on many years of experience.Our rotary pad printing automations offer highest precision in print image registration on convex, round or flat parts, one- or multi-colored. Additionally we offer with our brand ALFALAS® the laser marking ”Mark on the Fly” – bottle caps marking for competitions and promotion campaigns.

Request for a quoteResults for

Mixers for the beverages industry - Import exportNumber of results

12 ProductsCountries

Company type

Category

- Mixers and grinders for the food processing industry (6)

- Paint mixers and grinding machines (2)

- Beverage industry - machinery and equipment (1)

- Cement-making - machinery and equipment (1)

- Chemical industry - machinery and equipment (1)

- Mixers (1)

- Pad printing (1)

- Paper - disposable tableware and articles (1)