- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mixing arms for concrete mixers

Results for

Mixing arms for concrete mixers - Import export

QINGDAO PROMISING INTERNATIONAL CO.,LTD

China

Drum Rated Capacity: 4.8CBM Drum Actual Capacity: 3.9CBM Drum Concrete Output:14 CBM/hour, up to 4 batches per hour Drum Mixing Speed: 3 gears both Forward & Reverse Rotation Drum Max. Slewing Angle: 270degree (Optional) Engine: 95 kW (129 HP)/2400rpm YUCHAI 4108 Four-cylinder, Inline, Water-cooled, Four-stroke Turbocharged Diesel Engine Drive System Hydraulic Component: Danvers Variable Stroke Pump Gear Shift: 1 Forward, 1 Reverse, 1 High Speed, 1 Low Speed Low Speed: 0-9.5 km/h High Speed: 0-28 km/h Drive: 4-wheel Drive Gradeability: 30 degree Hydraulic System: Two Variable Stroke Pumps-Driving Vehicle and Mixer Separately, Two Constant Rate Pumps-Providing power to Drum, Brake and Water System Cabin: ROPS & FOPS Cabin Bucket Capacity: 0.6 CBM with Hydraulic Controlled Gate Chute: Hydraulically Controlled Adjustable Chute with 15 degree vertical movement and free horizontal movement Brake: Wet Brake, Parking Brake with Gear Box

Request for a quote

SICOMA OMG LTD

United Kingdom

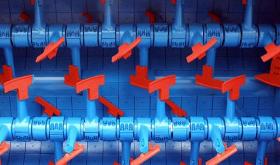

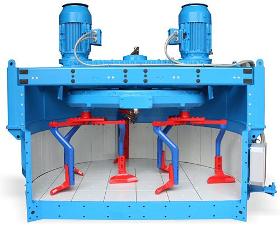

Our pan mixers, also known as turbine mixers, are ideal for both wet and dry cast concrete their design has been perfected over many years and now offer a fast and reliable mixing option. The mixer contains a series of individual mixing arms which are carefully positioned to both move the material from the hub of the mixer to the wall and back whilst also folding the material over itself during the process. Each mixing arm is support by an elasticated joint arm allowing the mixer to skip over smaller obstructions. Why choose a Sicoma OMG pan mixer? - Thorough mixing of both full and partial batches - Deep mixing chamber can be filled to full capacity - Large reduction gearbox means mixer can start with a full load - Fast and complete discharge ** Clicl to read more **

Request for a quote

SICOMA OMG LTD

United Kingdom

The most widely used, heavy duty twin-shaft models in the world today. Also known as double-shaft mixers, we have over 6000 in use from ready-mix to precast, block, paver and dam applications. Why choose a Sicoma OMG twin shaft mixer? - Range of sizes from 1 to 8 cubic meters - 24/7 continuous batch production - Central mixing reduces wear on outer liner tiles - NI-Hard tiles give longer life with extra-abrasive aggregates, with quick and easy replacement - Patented triple shaft seals act as one-way valve, with less grease use and no mix contamination - All gearboxes CNC manufactured in-house - Oil-bath lubricated gearboxes and bearings reduces maintenance ** Click to read more **

Request for a quote

SICOMA OMG LTD

United Kingdom

Planetary mixers are the industry standard for the most efficient mixing of all grades of concrete. The three blade ‘egg whisk’ mixing action on each head gives complete coverage of the entire floor of the mixing pan. The blades rotate on an ever-changing axis, as the gearbox spins the blade carrying spider. What makes Sicoma OMG mixers the best? - Range of sizes from50 – 4000 cu litres - Fast and thorough mixes for all types of dry-cast concrete - No dead spots - 30 second mixing time for most concrete mixes - Greater consistency, higher output and stronger mix - Fast and complete discharge - Hard wearing NI-Hard cast-iron liner plates for floors and walls - Optional internal high-pressure washer system to reduce clean-out time - Gearboxes manufactured in-house, double horizontal design is strong and shock resistant, with a horizontal oil bath to give every gear optimum lubrication and cool running. ** Click to read more **

Request for a quote

OPT MAKINE

Turkey

Mobile concrete batching plants - OPT-i60 is a model of mobile concrete batching plant with a capacity of 60 m3/hour compacted concrete production.

Request for a quote

SCANDINAVIAN & UK MACHINES

Sweden

The stationary concrete plant SUMAB T-60 is ideal for construction companies and building materials companies that want to obtain not only a high level of productivity but also a high level of concrete quality. Technical details: -Mixer volume 2250/1500 liters Sicoma Turbo (Italy) - 3 warehouses of inert materials of 30 m3 each with pneumatic dampers - 2 pumps for chemical additives ABB (Sweden) - Siemens computer (Germany), control cabin, system dosing Sumab (Sweden). Sumab T-60 plant advantages: - compact transportation of the plant saves you money; - installation of a concrete plant at any site; - production of more than 1000 types of concrete with the possibility of changing the recipe for each batch; - special painting is the guarantee of the plant's longevity; - automatic plant control.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Mixing arms for concrete mixers - Import exportNumber of results

6 ProductsCountries

Company type