- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- nitriding

Results for

Nitriding - Import export

HOMESHOP

Poland

It is hard to imagine operating electronic devices without the help of chargers. Anyone who wants to shorten the battery charging process, make it more effective and at the same time energy-saving should be interested in new generation gadgets. Baseus GaN2 Lite is an absolute hit on the market, which has a real chance to revolutionize it. Why? Because instead of silicon, it uses the power flowing from gallium nitride . GaNis a semiconductor material that not only improves the efficiency of the charging process, but also requires much less energy and takes up minimal space. Therefore, it is ideal for mobile use, also at work or traveling around the world. It is compatible with sockets around the world where electrical voltage standards range from 100 to 240 volts.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The H2Smart™ is an integrated sampling system designed to measure hydrogen content with high accuracy in nitriding and nitrocarburizing atmospheres and to calculate the parameters necessary for process control. Its unique measuring cell design and advanced electronics eliminate the need for a reference gas cell, thus simplifying the installation and usage. Moreover, the measuring cell is maintained at a set temperature to protect the system from condensation and contamination during nitrocarburizing and post oxidation processes. An integrated sampling pump with variable output insures reliable flow through the measuring cell. The sampling flow is continuously measured via an integrated mass flow meter, and, if necessary, the flow is adjusted by changing the pump output. In this manner, the closed-loop flow control assures reliable H2 measurement and thus accurate nitriding and nitrocarburizing control.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The SGS™ Single-Gas Sensor is an integrated thermal conductivity sampling system designed to measure the concentration of a gas sample in binary or quasi-binary mixtures. Ideal for measuring hydrogen (hydrogen sensor) content or dissociation level with high accuracy in nitriding and nitrocarburizing atmospheres, the SGS™ is also capable of calculating KN and KC for controlled nitriding and nitrocarburizing.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

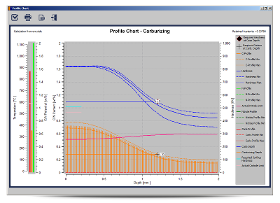

HT-Tools Pro is a powerful simulation tool for designing and optimizing recipes for carburizing including low-pressure carburizing, carbonitriding, as well as nitriding and nitrocarburizing processes. It can significantly reduce the lead time for process development, replacing time-consuming evaluations and trials.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Our modular control packages are customized to significantly improve your nitriding/nitrocarburizing operations, meet industry standards requirements and ultimately provide you with precise and reliable process control. We offer compact, fully automatic modules for new installations or retrofits. Each solution consists of a cost-effective module or combination of modules delivered with state-of-the-art equipment and backed by our extensive technological expertise. Nitriding / Nitrocarburizing Control Solution is supplied with a PROTHERM controller, hydrogen analyzer and optional NitroCarb™ probe for nitrocarburizing. Precise atmosphere control: KN, KC, KO or % dissociation. FEATURES • Full compliance with AMS 2750D, 2759/10A, 2759/12 (FNC), NFPA 86-C section 14-9, CQI-9, Nadcap* • Latest achievements in nitriding & nitrocarburizing process control • Cost-effective module configurations for new installations or retrofits * depending on the options chosen

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. Material Properties: * High thermal conductivity * Excellent thermal shock resistance * Low thermal expansion * Exceptional heat resistance * Good Chemical Inertness * High electrical resistance * Low dielectric constant and loss tangent * High volume resistivity * Excellent machinability

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina > Used for polysilicon ingot furnace, graphitization heat treatment furnace, vacuum sintering furnace, atmosphere furnace ect. Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Material of Boron Nitride Ceramics: Pyrolytic Boron Nitride: 99.99% Boron Nitride* 99 Boron Nitride: Boron Nitride + Boric Oxide (B2O3) CABN: Boron Nitride + Calcium Borate ALBN: Boron Nitride + Al2BO3 ZRBN: Boron Nitride + Zirconium Oxide + Boric Oxide (B2O3) ZABN: Boron Nitride + Zirconium Oxide + Aluminum Nitride + Al2BO3 SCBN: Boron Nitride + Silicon Carbon + Al2BO3 Processing of Boron Nitride Ceramics: 1.Hot Pressed Sintering 2.Chemical Vapor Deposition

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride (Si3N4) is a high-melting-point material with high fracture toughness and excellent thermal shock resistance, It is considered to be one of the few monolithic ceramic materials that can withstand severe thermal shock and thermal gradient generated by hydrogen and oxygen rocket engines.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

With its properties of electrical insulation and excellent thermal conductivity, Aluminum Nitride Ceramics is ideal for applications where heat dissipation is required. In addition, since it offers a coefficient of thermal expansion (CTE) near that of silicon, and excellent plasma resistance, it is used for semiconductor processing equipment components.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Bar: Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® Hot Press Boron Nitride Rod Diameter 32 mm, two length in stock (25 mm, 100 mm), custom length is available. White in color. Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Features of Boron Nitride High thermal conductivity Low thermal expansion Good thermal shock resistance High electrical resistance Low dielectric constant and loss tangent Microwave transparency Non toxic Easily machined — non abrasive and lubricious Chemically inert Not wet by most molten metals

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Factory Custom Silicon Nitride Thermal Substrate for High Power Radiator Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. Material Properties: * High thermal conductivity * Excellent thermal shock resistance * Low thermal expansion * Exceptional heat resistance * Good Chemical Inertness * High electrical resistance * Low dielectric constant and loss tangent * High volume resistivity * Excellent machinability Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. Material Properties: * High thermal conductivity * Excellent thermal shock resistance * Low thermal expansion * Exceptional heat resistance * Good Chemical Inertness * High electrical resistance * Low dielectric constant and loss tangent * High volume resistivity * Excellent machinability Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The crucible is produced by depositing pyrolytic boron nitride upon a mandrel having the shape of the desired crucible at a temperature of from about 1850° C. to about 2100° C. until a first layer of boron nitride of suitable thickness has been produced, interrupting the deposition of boron nitride upon the mandrel and lowering the temperature to below 1750° C., and then depositing additional boron nitride upon the mandrel at a temperature of from about 1850° C. to about 2100° C. to produce a second outer layer of boron nitride having a thickness greater than that of the inner layer. Features and Benefits of Boron Nitride ceramic 1. Easily Machinable 2. Exceptional Heat Resistance 3. High Thermal Conductivity 4. Low Thermal Expansion, Excellent Thermal Shock Resistance 5. Outstanding Electrical Insulation - even at high temperatures 6. High wet resistance to molten metals, slags and glass 7. Extreme Corrosion and Wear Resistance

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Boron Nitride is very often machined to isolation components which works in PVD euipments. They are be installed as replacement parts in PVD Magnetron sputtering systems. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina PVD/CVD vacuum coating equipment insulation accessories > Used for ion coating machine, sputtering coating Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron Nitride Specifications: >Outside Diameter: 6.40 mm >Inside Diameter: 1.70 mm >Wall Thickness: 2.35 mm >Length: 100 mm >Condition: Hot Pressed >Custom size is available. White in color. Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials, this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Features of Boron Nitride: 1.High thermal conductivity 2.Low thermal expansion 3.Good thermal shock resistance 4.High electrical resistance 5.Low dielectric constant and loss tangent 6.Microwave transparency 7.Non toxic 8.Easily machined — non abrasive and lubricious 9.Chemically inert 10.Not wet by most molten metals

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® Hot Press Boron Nitride Sheet Thickness 2 mm, 3 Square in stock (25 x 25 mm, 50 x 50 mm, 200 mm x 240 mm), custom size is available. White in color. Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Features of Boron Nitride: 1.High thermal conductivity 2.Low thermal expansion 3.Good thermal shock resistance 4.High electrical resistance 5.Low dielectric constant and loss tangent 6.Microwave transparency 7.Non toxic 8.Easily machined — non abrasive and lubricious 9.Chemically inert 10.Not wet by most molten metals

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

BN is a material with non-wet feature. So molten metal won’t be sticked onto the nozzle. Additionally, Boron Nitride ceramic is a kind of refractory ceramic with low expansion and high thermal conductivity. These features make it to be an ideal choice as atomizing nozzles. It's very easy to be machined to custom design with precision and tight tolerance because of its machinability. Boron Nitride Ceramic BN Nozzles Performance: 1.The optimized formula and unigque process make it highly resistant to thermal shock and high-temperature creep.Maximum using temperature 1700°C. 2.Low thermal expansion coefficient,no cracking or deformation during use. 3.Strong erosion resistance,wear resistance and metal corrosion resitance.Long service life. 4.Good raw materials,process control,product stability. 5. It is used in Amorphous Ribbon Making and amorphous nozzles.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

At present, conventional insulation materials have disadvantages such as low temperature resistance, low purity, gas release at high temperature, poor toughness, no insulation at high temperature, and easy to be corrosed. PBN insulation board can solve these problems. Name: high temperature resistant BN gold melting crucibles Borons Ceramic Main Features: 1. The maximum tolerance is 2300℃ in vacuum and 2700℃ in ammonia atmosphere; 2. High purity, high temperature does not release gas impurities (>99.99%); 3. Good toughness (hexagonal structure similar to graphite); 4. High temperature insulation (volume resistivity 3.11×1011 ω •cm); 5. Intensification of inert, acid, alkali, salt and organic solvent corrosion; 6. Low thermal conductivity in the DIRECTION of C can block the downward conduction of heat and reduce heat loss

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quoteResults for

Nitriding - Import exportNumber of results

103 ProductsCountries

Company type

Category

- Ceramics, industrial (58)

- Ceramics (6)

- Ceramics, refractory (5)

- Gloves (5)

- Screw cutting - steels and metals (5)

- Ceramic manufacturing - machinery and equipment (4)

- Paints, synthetic resin (3)

- Metallurgy and iron and steel industry - machinery and installations (2)

- Branding equipment (1)

- Energy and raw materials - services to industry (1)

- Heat treatment furnaces (1)

- Heat treatment of steels and metals (1)

- Internal transport systems (1)

- SMALL METAL PARTS (1)

- Siliceous limestone bricks (1)

- Stones & Minerals (1)