- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- non ferrous piping

Results for

Non ferrous piping - Import export

NOVELTY STEEL

Turkey

Pipe supports are essential components of piping systems. Choosing the right support type is essential for a cost effective and well performing piping system. Novelty Steel fabricates; * Pipe Racks * Structural Supports * Pipe Shoes * Anchors * Rods * Rollers

Request for a quote

NOVELTY STEEL

Turkey

Piping includes a pipe or system of pipes, pipe spools, tubing, fittings, expansion joints, hoses, or other pressure bearing components as appropriate. Pressure piping systems transport fluids under pressure. Components of pressure piping include: a. Pipes: The main conduits for fluid transport. b. Fittings: Connectors, elbows, and tees that join pipes together. c. Valves: Used to control and regulate the flow of fluids. d. Flanges: Connect pipes to other components like valves, pumps, or tanks. Novelty Steel is an experienced fabricator of pressure vessels for power, oil and gas, chemical, food and mining industries. With vast CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke CNC Machined parts according to the European Norms. Our fabrication portfolio covers: * Pressure Vessels * Boilers * HRSGs * Heat Exchangers * Pipe Spools * Piping Components * Pipe Supports * Process Skids

Request for a quote

PIERON GMBH

Germany

Dimensions Depending on the required stamp power (material strength, material thickness, and part shape) Material All spring materials in soft and hard condition as well as quality steels with lower strengths and aluminum alloy and also special alloy Stainless steel up to 1900 N/m² Rubber-coated strip material Hardening Through external services Coating Fully or partly coated strip material In-house phosphating In-house stove-enameling Additional coatings through external services Specialities Fully automated manufacturing of components and mounting Fully automated welding Contact springs with contact rivet Bushes clinched, welded, and open Special processing like thread cutting, screw mounting, and rivets feasible Special packaging in blister pack, trays or magazines Rapid prototyping

Request for a quote

ANTHERMO GMBH

Germany

(Socked-Weld-Fittings) Straight from our warehouse We always have numerous versions of weld-in fittings (ANSI B 16.11) available in our extensive warehouse in Kamen. We can also supply you at short notice. We only deliver goods of European origin. 3 types of reducing inserts Insert reducers are available in three different types (see technical data sheet in the download area). Standards and special requests We supply weld-in fittings as standard in two pressure levels (3000 lbs and 6000 lbs) and in all common materials. We can also supply 9000 lbs and special materials if required. Technical specifications You can find more details, technical data and dimensions in our data sheet "Weld-in fittings" in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Elbows and connections made of steel and stainless steel for oil, gasoline and air hose lines. The connections are pressed onto the assembled hose.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Super lightweight reusable dash aluminum fittings. Manufactured according to aviation standards, suitable for petrol, oil, methanol, water and air. The first choice when it comes to reliable and flexible hose lines.

Request for a quote

ANTHERMO GMBH

Germany

Buttweld fittings according to ANSI B 16.9 Extensive stock range in special materials We can deliver Buttweld Fittings in numerous dimensions and materials directly from stock at short notice. Pipe bends with different radii (seamless and welded), T-pieces, reducers and caps essentially make up the product groups Buttweld Fittings (buttweld fittings). We only deliver goods of European origin. Special materials In particular, we supply special materials, which are generally only rarely requested, at short notice from our extensive range in stock. The following special materials are available at short notice: Low Temp Steel A 420 WPL6 / WPHY52 Chrome-Moly A234 Alloy WP5 Chrome-Moly A234 Alloy WP11 Chrome-Moly A234 Alloy WP22

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Fewer steps to the finished workpiece With t project you can see all the variables of the bending process before you start the production. Adapted to the material and collisionfree, it makes it possible to plan and execute complex bending geometries. The virtual bending simulation determines exact bending timings and cutting lengths; it also tests tube geometries in advance for feasibility. Tube data and bending results are documented with accuracy and they can then be replicated 100% . All the most common interfaces are available for the import and export of data and connection to BDE or ERP over the network.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Labelling systems can be integrated, whether it is laser, needle or inkjet, to mark and identify the tubes. Other options that can be integrated are welding seam detection, length control or measurement of processed tubes. The corresponding sensor and camera technology can be implemented for the specific product. The following step can be carried out without any problems, whether it is cutting, punching, deburring of holes or seal testing with external systems. Smart data evaluation All the systems can be equipped with different control and IPC panels. Interfaces to data caption systems for consumption and operation make the digitalization and evaluation of the data. Marking system, Welding seam detection, Camera control system, Internal and external cleaning processes, Cleaning and suction, Hole punching, Deburring – chamfering

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The right system for every need There is a great variety of handling systems available, dependent on the length of the workpiece. For short tubes there are systems gripping from below with insertion axis and for long tubes there are systems handling from above. Both options can be used in our combination systems. They guarantee ideal access for the operator, so they can complete the setup and any maintenance operations in the best possible way. Transfer stations, turning modules for processing the tube in both directions within an installation and multiple grippers are available for optimized processes. Handling robots from many different manufacturers can also be integrated. The robots are used to move tubes/workpieces. A preassembly of different workpieces is also feasible in this case. The various components can be sorted using sensors and robots.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We offer a great variety of loading systems for all the machines, dependent on the material, tube diameter and tube length. Tubes that have already been formed and with added components can also be loaded without any issues. The appropriate orientation is therefore very important, when loading the tube into the production cell. External workpieces, such as nuts, flanges, supporting sleeves can be added to the system in a controlled manner and included in any subsequent processing steps. A great variety of loading volumes is possible. Step feeder, Conveyor feeder, Chain feeder, Swivel arm feeder, Loading tables, Bowl feeder, Alignment station

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Clean, efficient, versatile. transfluid's knife cutting method is ideal for postbending cuts. Even with extreme geometries it is possible to have perpendicular cuts with sharp edges. In both cases both chips can easily be detected in the process. Extreme requirements are also not a problem, as up to two blades can be used. An internal mandrel can also optimise the process.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Created for precision. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can then be directly processed further and for instance be formed straight afterwards. That saves time and money.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

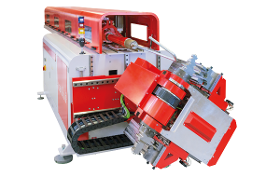

In form, double strength. For the optimum processing of your individual requirements we simply combine our transfluid forming techniques, as simple as that, in particular the axial forming and the rollforming. The additional clamping unit makes even extreme forming feasible in one work sequence. The cutting before the axial tube forming is also possible, as well as the rollforming of a preformed geometry. That saves you valuable time. A strong partnership axial forming and rollforming. Our t form combination machines is the perfect union of axial and rolling tube processing, with up to 6 axial forming steps, two rollforming stations, two powered tool holders for flange orientation and an additional clamping unit. The horizontal clamping system makes the processing of bent tube geometries possible.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Powerful and fast forming. The type UMR tube forming machine uses smart operating technology with many preset settings that can be retrieved automatically to achieve perfect mirrorlike surfaces. When producing flaring with 20°90° angles, with a clamping length of 1 x D, the machine achieves perfect sealing surfaces. Flaring up to 90° can be produced in a single cycle. Tools can be changed extremely quickly. With the appropriate tools the machine can also close tube ends.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

All the options in one single machine forming, cutting, postbending cutting, threading. Our rotational technology increase the possibilities of forming on tubes with minimal expenditure on tools. All the drives are servoelectric by design and, if needed, CNCoperated. In our SRM typeforming machines, all the settings are preloaded, so there is no longer any need for costly adjustments. Different tool variants further expand the processing possibilities for chipless cutting or postbending cutting. The machines can produce internal and external profiles and can also roll in synchronicity thanks to a special tool head (inside/outside).

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Accurate forming with fast tool change. Our type REB axial t form forming machines, with their compression power of up to 1,300 kN are particularly wellsuited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step userfriendly and fully programmable individually. We offer the option to equip our systems with electric or hydraulicnumerical drives. These forming processes can be completed stepwise in transfer system to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TRANSFLUID® MASCHINENBAU GMBH

Germany

We have developed these t bend machine solutions strong> for fast and efficient processing times. They are specifically tailored to the challenges of individual bends. Whether the system is manual or automated, they will deliver the best possible results. Highly efficient This manufacturing accelerator offers the profitable efficiency of our high performance bending machines for the manufacturing of hydraulics fittings together with Top Speed that is what the "AB" series stands for. For individual bends from 1xD to 1,500 mm bending radius for small and large radii, for demanding materials with thin walls, the high performance (HP) machine series guarantees the perfect bending result.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Stable, flexible and economical. This series will win you over with its special stability and performance. Individual pieces and small series can be produced in an extremely economical manner with this machine concept. The use of highvalue components ensure the machine's durability.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times.Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most extreme geometries on tubes. With our clockwise/counterclockwise bending machines – also available with push bending function – the most complex bends become reality with great accuracy.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Compact and very efficient. Our fully hydraulic mandrel bending machine delivers outstanding bend quality and very simple handling, with SPS control for preselection and storage of bending angles via a touch panel.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality.

Request for a quote

KAUFMANN GROUP

Slovakia

Our experts are dedicated to thorough material preparation prior to welding, including grinding, cleaning, and even material fitting. Their meticulous work ensures that the material is optimally prepared for welding, thereby enhancing the final quality.

Request for a quote

PIRPED INTERNATIONAL

France

Standards : EN 1092-1, DIN, ANSI B16.5 Dimension : DN15-DN600, 1/2"-24" Pression : PN2.5-PN160, 150Lbs-2500Lbs Material :Acier Carbonne, Allié, Inoxydable, Duplex & Super Duplex et autres…

Request for a quote

PIRPED INTERNATIONAL

France

Standards : EN 1092-1, ANSI B16.5, ASME B16.47 Dimension : DN15-DN2000, 1/2"-60" Pression : PN10-PN400, 150Lbs-2500Lbs Material :Carbon Steel, Alloy, Stainless Steel, Duplex & Super Duplex and others…

Request for a quote

PIRPED INTERNATIONAL

France

Standards : EN 1092-1, DIN 2566, ANSI B16.5, BS 4504, JIS B2220 Dimension : DN15-DN1000, 1/2"-24" Pression : PN6-PN100, 150Lbs-2500Lbs Material : Carbon Steel, Alloy, Stainless Steel, Duplex & Super Duplex and others…

Request for a quote

PIRPED INTERNATIONAL

France

Standards : EN 1092-1, DIN 2631-2638, ANSI B16.5 B16.47, BS 4504, JIS B2220 Dimension : DN15-DN2000, 1/2"-60" Pression : PN2.5-PN400, 150Lbs-2500Lbs Matière : Carbon Steel, Alloy, Stainless Steel, Duplex & Super Duplex and others…

Request for a quote

PIRPED INTERNATIONAL

France

Standards : EN 1092-1, DIN 2527, ANSI B16.5 B16.47, BS 4504, JIS B2220 Dimension : DN15-DN2000, 1/2"-60" Pression : PN2.5-PN400, 150Lbs-2500Lbs Material : Carbon Steel, Alloy, Stainless Steel, Duplex & Super Duplex and others…

Request for a quote

PIRPED INTERNATIONAL

France

Standards : EN 1092-1, DIN 2642, ANSI B16.5, BS 4504, JIS B2220 Dimension : DN15-DN600, 1/2"-24" Pression : PN2.5-PN40, 150Lbs-1500Lbs Material : Carbon Steel, Alloy, Stainless Steel, Duplex & Super Duplex and others…

Request for a quoteResults for

Non ferrous piping - Import exportNumber of results

265 ProductsCountries

Category

- Pipe and tube fittings - ferrous metal (181)

- Pipe and tube fittings - non-ferrous metal (37)

- Pipes and tubes - ferrous metal (37)

- Mains pipes - ferrous metal (7)

- Pipes, bent - ferrous metal (5)

- Industrial piping (3)

- Pipes and tubes - non-ferrous metal (3)

- Pipes and tubes, stainless steel (3)

- Seamless pipes and tubes - ferrous metal (3)

- Cutting - steels and metals (2)

- Expansion joints - ferrous metal (2)

- Expansion joints - non-ferrous metal (2)

- Gas fittings (2)

- Casting, steel (1)

- Elbow Pipes - non-ferrous metal (1)

- Gas and oil pipelines - installations (1)

- Pipes and tubes, steel (1)

- Profiled sheets - ferrous metal (1)