- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pipe bending tools

Results for

Pipe bending tools - Import export

KW HYDRAULIK GMBH

Germany

Pressing Pipes Bending Pipes Striping and Peeling of Tube Brochure Tools for Pipeline Construction Drilling of Tubes Cutting and Sawing of Tubes Chamfering Tool for Plastic Tubes

Request for a quote

TECHNIC MACHINES

Turkey

Our Double Head Tube Bending Machine model designed for higher productivity, if you compare with typical mandrel pipe bending machines. It can give 8 times production capacity, designed for fast pipe bending work. - Semi Automatic Double Head Pipe Bending Machine This model manual angle control, also it gives chance to second dimension with manual rotation adjustment. It will give you high capacity with low investment cost and long using life. - Automatic Double Head Pipe Bending Machine This model has automatic angle control, also it gives chance to sequently automatic multiple angle adjustment to have several bending angles. Distance adjustment between the bendings is also automatic on our this model.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

The advantages to you: no more deformation of roundness when cutting bends on site easier extension-pipe/tiered pipe bend construction appealing visually pickled surface All of our pipes and pipe bends (both unannealed and annealed) are made of the following material: stainless steel pipe, material no. 1.4301 (AISI 304) longitudinal seam welded pipes hot rolled & cold rolled coils, unannealed, with or without pickling (W1) Make: IltaInox and/or Marcegaglia

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Glass pipe bends For conveying abrasive media or for high flow rates, we can supply you with glass pipe bends made from 3.3 borosilicate glass with a copper grounding strip. These have a service life at least 10 times longer than that of stainless steel pipe bends. made of 3.3 borosilicate glass leg extension 200 mm copper grounding strip attached at the outer radius

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

In pneumatic conveying systems, conveying abrasive products – in particular at high conveying speeds – leads to abrasion and thus to wear in the pipe bends. In order to prevent this, the pipe bend of our highly wear-resistant DWR double-skin stainless pipe bends is encased in a second pipe bend, which creates a double-walled chamber. This acts, so to speak, as a “protective shield”: After the wear has taken place on the internal pipe bend, it fills with the product to be conveyed. When this process is completed, you are then conveying „product on product“ – and no further wear is possible! Version I: „Product-on-product” In this variant, the classic “double skin” comes into effect. not suitable for foodstuffs not suitable for material change Version II: „Lined with concrete” lined with extremely hard concrete colour: light grey not suitable for foodstuffs also available: lined with borosilicate glass

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

We can supply you with highly wear-resistant stainless steel pipe bends which have a service life 10 to 20 times longer than that of standard stainless steel pipe bends. This high degree of wear protection is required, for example for conveying fibreglass-reinforced plastic granules or similarly abrasive media. suitable for use of highly abrasive products easy installation no stepped pipe couplings and no flange connections required safe for use with food

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

We produce aluminium pipe bends with the following characteristics and product specifications: DIN EN 573-3, 755-1, /-2 /-9

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Our speciality are thin-walled pipe-bends with large bending radius, especially for pneumatic conveying systems. The pipe-bends are cold-bent without any pleats on CNC-mandrel machines. Our quality management generally guarantees: welded seam smoothed or shaved (DIN 11 850 resp. DIN 17 457) absolutely wrinkle-free, no start-up bulges no scratching or scoring extremely low ovality visually aesthetic surface leg extension each side deburred sawing edges

Request for a quote

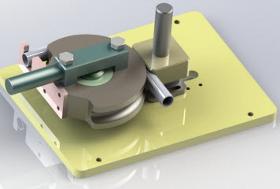

TRANSFLUID® MASCHINENBAU GMBH

Germany

We have developed these t bend machine solutions strong> for fast and efficient processing times. They are specifically tailored to the challenges of individual bends. Whether the system is manual or automated, they will deliver the best possible results. Highly efficient This manufacturing accelerator offers the profitable efficiency of our high performance bending machines for the manufacturing of hydraulics fittings together with Top Speed that is what the "AB" series stands for. For individual bends from 1xD to 1,500 mm bending radius for small and large radii, for demanding materials with thin walls, the high performance (HP) machine series guarantees the perfect bending result.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites: a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality. Tube measurements up to 60 mm, up to 80 mm and up to 115 mm are covered, depending on the machine. It is also feasible to bend tubes with imperial sizes with the standard tools.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites: a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality. Tube measurements up to 60 mm, up to 80 mm and up to 115 mm are covered, depending on the machine. It is also feasible to bend tubes with imperial sizes with the standard tools.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites: a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality. Tube measurements up to 60 mm, up to 80 mm and up to 115 mm are covered, depending on the machine. It is also feasible to bend tubes with imperial sizes with the standard tools.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites: a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality. Tube measurements up to 60 mm, up to 80 mm and up to 115 mm are covered, depending on the machine. It is also feasible to bend tubes with imperial sizes with the standard tools.

Request for a quote

METAL-TECH

Poland

DIE FOR A PELLET MACHINE, MAKING DIES AND ROLLS CUSTOM

Request for a quote

BASAK LAZER

Turkey

We can shape metal materials with our press brake machine with a capacity of 380 tons. We can shape your aluminum, stainless steel and ST series metal sheets in the desired form.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELEKTRON SP. Z O.O.

Poland

We provide the metal profile and pipe bending services. We offer the bending of pipes and profiles from both classical and structural steels of various sizes on machines of a new generation. These machines work with the utmost precision and make it possible to produce almost any shape. Material possibilities: • Pipe processing parameters: - 20 x 1.5 mm (rollable) - 21.3 x 2 mm (rollable) - 33.7 x 2 mm (rollable) - 42.4 x 2 mm (rollable) - 42.4 x 3.2 mm (rollable) - 48.3 x 2 mm - 60.3 x 2 mm • Profile processing parameters: - 40 x 40 x 2 mm - 30 x 30 x 1.5 (rollable) - 40 x 20 x 1.5 (rollable) Is your question more comprehensive or more general? Send us an email at biuro@web-elektron.pl and we will propose the most suitable solution after its processing.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

Mandrel bends kit,Mandrel bends

Request for a quote

SINOP SMP

Czech Rep.

Die Bending with Press Brake Custom manufacturing as well as large volume production Software simulation of bending feasibility CNC programming of press brakes from office “Z” bend, flattened hems and radius bends Bending flexibility thanks to 6-axis backgauge Maximal bending length 3000 m, maximal sheet thickness 10 mm

Request for a quote

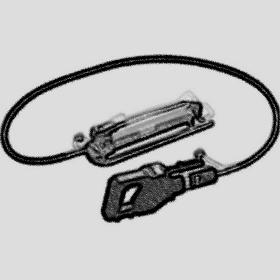

UNIFLEX-HYDRAULIK GMBH

Germany

The UBM 6-20 M is a universal bending device for steel pipes up to 20 mm OD. It comes with a set of bending rolls for common applications. An integrated scale for angle detection helps you to reach the required pipe dimension in only one work step. The telescopic lever keeps the operator’s forces low when bending rigid pipes. •Compact design •Compact for mobile usage •Standard with a set of 6 bendings rolls •User friendly •Easy handling •Simple adjustment •Wide workpiece range •Innovative design •Angle scale included •Telescopic lever

Request for a quote

MAHERAS LTD.

Bulgaria

We have 2 tube bending machines. One for small radii and one for large radii.

Request for a quote

MR CO. LTD.

Ukraine

Two methods are used to bend pipes at a certain angle, hot and cold. We provide cold-bending pipe services. Products made of plastic metals and alloys lend themselves well to this technology. Bending pipes by this method is possible only if their diameter does not exceed 100 mm. This type of machining is done manually or through special bending machines. When bending round pipes, it is essential to avoid dents that decrease their inner diameter. The pipes should have smooth bends along a certain radius and a circular shape in the bend areas. Our pipe bending machines allow you to get a quality bend in a few rolls.

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC bending up to 3000 mm 100T; - bending of threaded rods up to D12.

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Bystronic-Beyeler (Euro-A, RF-A, R, S), Edwards Pearson, Safan, Bystronic, Beyeler etc. We supply solid pieces 100, 500, 1000 mm; section set (cutted) 1100 mm and complete sets for the full length of your press brake. Dies could be used with Trumpf-WILA system. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

PRECITOOLS SRLS

Italy

Press brake tools for machines: Accurl, Adira, AM Machinery, Amada, Augusta, Axial, Baykal, Boschert, Bystronic, CMU, CoastOne, Colgar, Colly, Gasparini, Gilardi, Gizelis, Guifil, Dener Makina, Deratech, Durma, Edward Pearson, Ermaksan, Euromac, Femas, Fratelli Farina, GADE, Gasparini, Gecko, HACO (Atlantic), Hammerle, Hesse, Hezinger, Hilalsan, IMAL, Inanlar, Ironmac, ITEK, Jean Perrot, Jordi, KAAST, Karmet, Kingsland, Knuth, LAG, Mecos, MVD, Muratec, Nargesa, OMAG, Peliant, Rico, Salvagnini, Schiavi, SMD, STR, Tabama, TCI etc. We supply solid pieces 415, 835 mm; section set (cutted) 805 mm and complete sets for the full length of your press brake. We can provide special press brake tools, study the projects and drawings, virtual simulation of bending process and study of the available tonnage and possible limitations of bending. All main press brake tools could be supplied within 1 working week. We are available to make quick and professional delivery to any part of European Union.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

All kinds of bending types can be set up with EHRT bending machines. Offset bending, flat bending, bending on edge, torsion bending, closed shapes and U-bends are some examples. The machines offers an outstanding bending accuracy of 0.2°. With the EB40 Professional E, side lengths up to 2000mm can be bent with ease. The tool change on the machine is carried out through a user-friendly plug-in system. This guarantees very fast setup times, yet robust and precise bending tools. The “E” in the name stands for the electric drive of the machine, which enables energy savings of up to 70 %. Due to the absence of a hydraulic unit, which is no longer needed, the machine is significantly more quiet and requires little maintenance. The CNC-controlled side stop is equipped as standard. The machine’s larger tables allow the operator greater degrees of freedom in the bending process, especially with more complex workpieces.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

EHRT's standard bending machine EB 40 is distinguished by their extreme robustness and simple handling. The machine is modulary and flexibly structured, so that each machine can be individually adapted to the customers’ needs. EHRT bending machines can perform a multitude of bending modes. Offset bending, flat bending, edge bending, torsion bending, closed shapes and U-bends are some examples. The hydraulic cylinder of the bending machine is fitted with a force of 344 kN. The machine offers an outstanding bending accuracy of 0.2°. A special plug-in system makes tool changing very user-friendly on the EHRT machines. This guarantees very fast setup times and yet robust and precise bending tools. Beckhoff's PLC machine control enables machine maintenance and software updates via remote access.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

EHRT's standard bending machine EB20 is distinguished by its extreme robustness and simple handling. The machine is modulary and flexibly structured, so that each machine can be individually adapted to the customers' needs. EHRT bending machines can perform a multitude of bending modes. Offset bending, flat bending, edge bending, torsion bending, closed shapes and U-bends are some examples. The hydraulic cylinder of the bending machine is fitted with a force of 222 kN. This machine offer an outstanding bending accuracy of 0.2°. A special plug-in system makes tool changing very user-friendly on the machine. This guarantees very fast setup times and yet robust and precise bending tools. Beckhoff’s PLC machine control enables machine maintenance and software updates via remote access.

Request for a quoteResults for

Pipe bending tools - Import exportNumber of results

36 ProductsCountries