- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process automation

Results for

Process automation - Import export

ENGINEERING TECHNOLOGY CORPORATION

United States

Process automation ranging from simple barcode reading to full-scale automated work cells. A large variety of robotic technologies are available to improve manufacturing safety, efficiency, and accuracy.

Request for a quote

B:TECH

Czech Rep.

We are experienced in complex supply of industrial automation in the field of process and production technologies. Our services include creation of all the steps of project documentation, a draft of the control system including functional safety, programming of control systems, and creation of operator interface. In terms of turnkey projects, we take care of full material supply including their assembly and installation for the customer. We fully revive the system, put it into operation, and provide future service. In the area of process automation we focus primarily on the supply of turnkey electrical engineering projects to build or modernize industrial technologies. We will suggest a solution for you, create all steps of project documentation, ensure material supplies and their installation. We will provide software development for technology management, put it in operation and take care of the repair services.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Business sectors : environment and renewable energy peripheral equipment for the transport of lightweight consumer goods (≤ 10 kg) by autonomous drones via aerial highways peripheral technological equipment for self-driving land vehicles development and integration of specialist digital solutions for automated production processes

Request for a quote

DOREY

France

Our M100 is built to your production needs. With multiple roll production and an array of finishing options you can produce any product. Our M100 can accommodate any seam type, cut to length options, process controls all automated to increase your production. SPECIFICATIONS, FUNCTIONS AND BENEFITS AUTOMATED Hands free, continuous operation for high speed production for an array of applications CUSTOMIZATION Like many of our machines we will customise a complete system for you. Choose your technology, pick your seam types, add any finishing

Request for a quote

DOREY

France

The M 100 is a completely automated production process. From overlaps and hems to grommets and keder, the M 100 will do all welding in one pass through the machine. The M 100 is also able to cut your panels to specified lengths. The M 100 will greatly increase production while decreasing labor costs. FEATURES, FUNCTIONS, & BENEFITS The machine includes Two or more unwinders for PVC covers Two unwinders for reinforced tape for Keder Two unwinders for rope Five hot air welding heads (or more) One cutting system to cut the cover at the desired length

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

We offer the full range of solutions for process automation tasks implemented with Foundation™ fieldbus and PROFIBUS-PA: The portfolio includes power supplies, power conditioners, multibarriers as well as junction boxes in IP20 and IP67. The range also includes passive connectivity products such as fieldbus cables, field distributors and terminating resistors. The components are suitable for use in harsh environments and can directly be mounted on the machine or in the process.

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

Our modular fieldbus and remote I/O-systems offer a comprehensive range of solutions for factory and process automation with interfaces for the fieldbus protocols PROFIBUS-DP, DeviceNet™, CANopen, Modbus TCP, Ethernet/IP™ and PROFINET. excom® is a remote-I/O-system in IP20 for Ex and non-Ex areas. You can plan and implement tailor-made solutions for the I/O IP20 area with the universal BL20 bus terminal system. The modular IP67 fieldbus systems BL67 and piconet® can be mounted directly in the field.

Request for a quote

SAMSYS GMBH

Germany

With a fixed storage tray, the ProFeeder Light palletizing robot from EasyRobotics is ideally suited for automated processes of small series. A cost-effective application that sets new standards in precision machining when combined with a robot from Universal Robots. Equipped with special software and the help of UR+ Caps, set-up times as well as machining times can be greatly reduced. In addition, employees can concentrate more on more important activities and increase productivity.

Request for a quote

SAMSYS GMBH

Germany

The ProFeeder Compact from EasyRobotics is a robust robotic cell with compact dimensions that can be easily moved in your production. The ProFeeder Compact is placed separately in front of the machine to be operated. Then an ER Work or an ER Pedestal is positioned in front of the machine. The robot is located on the ER Work / ER Pedestal. The robot now takes workpieces from the ProFeeder Compact and loads and unloads the machine. It then loads the workpieces back into the ProFeeder Compact. This results in advantages for you, such as more space in your production, quick adaptability for different workpieces and a mobile robot cell. Thanks to the simple design of the drawers of the ProFeeder Compact, workpieces of various sizes and lengths can be processed without major changeover work.

Request for a quote

SAMSYS GMBH

Germany

With the new intelligent OnRobot screwdriver for light industrial, cooperation and assembly robot you can easily automate processes. Intelligent error detection and handling of multiple screw sizes ensures consistent results and drastically reduces your cycle time. Seamless integration with the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc. Functionality Due to the simple connection of the screwdriver and the operation and programming via the own URCap (only applies to Universal Robots) the grippers are ready for use in the shortest time. In addition, the connection time is reduced by the OnRobot quick-change system Quick Changer and Dual Quick Changer.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Welded Tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP® and can be constructed individually in diameter in volumes of 50 to 10,000 m³ according to the application. LIPP® offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to highalloy stainless steels. The automated process meets the highest quality standards. LIPP® Welded Storage Tanks can be produced within a short time, either on site in the open air or inside a building.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

A CMMS is a software solution that centralizes maintenance information, facilitates processes, and automates some tasks to improve efficiency. Computerized maintenance management system software optimizes the use, availability, and life span of equipment, machinery, fleets, infrastructures, facilities, or operations.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® DP-EU pressure blasting cabinets clean and process tools and parts in just a few seconds. Fine blasting granulates are shot onto the surface by means of compressed air and remove dirt and corrosion. The blasting nozzle is manually guided during the processing of individual parts. Process automation is also possible. For this purpose, the workpiece or the blasting nozzle is moved by motor. The pressure blasting process is suitable for the removal of all solid, exposed residues and layers, especially on metallic surfaces of production tools and high-quality machine parts. Deburring and finishing of surfaces is also possible. In extensive tests with your tools you can convince yourself of the economic efficiency of our system. We will provide you with a test facility for this purpose after consultation.

Request for a quote

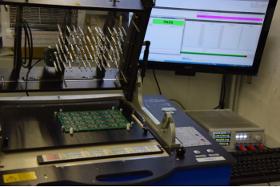

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Placement tests, checking the electrical and software functionality, launch tests – depending on your individual requirements and your component, we will develop a test strategy and tune the tests to fit with each other. Our comprehensive test development methodology accelerates processes running all the way to the delivery of your product and reduced testing costs.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. When planning tests, we work to your test specifications or develop a cost-optimised, efficient concept. In our tests, we simulate real usage conditions. In this way, we make sure that devices, systems or components will function correctly. Quality management at PRUFREX also includes developing efficient testing strategies.

Request for a quote

MTA ROBOTICS AG

Switzerland

The laser MRC500 is the larger robotic cell that supports point to point laser soldering from above. The standardized platform is based on a flexible and modular concept that can be adapted to a range of processes from fully-automated in-line to stand-alone semi-automated processes. The frame of the laser MRC500 is designed to ensure the safety of the operator during the laser soldering process. Furthermore, it also provides maximum accessibility to the working area. The laser robotic cell is only equipped with mta MLH45 laser head. The main features of our laser MRC500 include: Welded frame construction 3-axis Cartesian robot 500x500mm working area Industrial PC controller with Embedded Windows® operating system Intuitive menu-driven mta MotionEditor software

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

mainSENSOR is based on an innovative measuring principle, which has been developed by Micro-Epsilon in order to combine the advantages of both inductive and magnetic sensors. Magneto-inductive sensors are frequently used as alternative to inductive sensors and proximity sensors in process automation, the packaging industry and in machine monitoring. Measuring the distance to a magnet which is fixed at the measurement object, the sensor outputs a continuous, linear signal. As different strength magnets are applied, measuring ranges of between 20 mm and 55 mm can be achieved. However, in order to adapt the measuring range, it is only necessary to change the magnet.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EC PLAZA

South Korea

Manufacturing Process Modeling file Conversion >Modifying a Model > 3D Output > Post-processing > Painting > Display stand glass case > Inspection & Delivery Features 1)Cost reduction : Reduce production costs by 30% through the process improvement, automation, and professional modeling. 2)Shortened period : Reduce production period by 50% (30~45 days) compared to the existing manual production method.(60~90 days) 3)Eco-friendly materials : Produce tailored to international trends by printing shapes using eco-friendly materials. 4)Process automation : Jun Engineering's simplified system reduced manufacturing process from 21 steps in to only 7 steps. 5)Technical security : From Book-data-based process, improve to Security server and network based data acquisition for technical security. Application We usually use modeling and 3D Printing in various field, such as producing maritime structures. You can make anything if you want.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

IN STEEL AND STAINLESS STEEL FROM 50 – 10,000 M3 LIPP welded storage tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP and can be constructed with steplessly adjustable volumes of 50 to 10,000 m³ according to the application. LIPP offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to high alloy stainless steels. The automated process meets the highest quality standards. LIPP storage tanks can be produced within a very short time, either on site in the open air or inside a building. The special circumferential profile ensures additional stability compared to conventional processes. KEY BENEFITS Three different welding processes based on the LIPP system and adjusted to the application

Request for a quote

EC PLAZA

South Korea

The process of Infeed Shaker 1. Conveying 2. Dewatering 3. Grading 4. Sieving Product Features 1. Equipment that hygienically transports food, grain, and medicines using vibration. 2. Once the equipment is installed, stable and semi-permanent transportation is possible. 3. Install a feeder suitable for the customer's on-site conditions. 4. Various types of infeed shaker designs for each sample. 5. Securing equipment safety through analysis and simulation. Our Company DUK YOUNG ENGINEERING Based on powder and liquid mixing technology for the past 30 years, our company provides total engineering service of automation processes required throughout the industry, such as storage, transfer, metering and input.

Request for a quote

EC PLAZA

South Korea

Seunggwang's challenge to consider safety and eco-friendliness for the future of autonomous vehicles continues. "Seunggwang's challenge for molds that consider safety and eco-friendliness continues." All employees cooperate with each other, and we have received a lot of favorable reviews and trust from customers through win-win management with our partners based on a proactive work attitude, good quality, compliance with delivery, and credit transactions. We hope to become your trustworthy partner as a company that focuses on developing high-quality molds by practicing ESG management, becoming smart by building a smart factory, building a quick work process, standardizing molds by CAD/CAM, and automating process work.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). To manufacture self-supporting coils, we use self-bonding wire. During winding, the surface of the wire is bonded using hot air. To ensure the coil connections can be soldered, they are then stripped of insulating enamel using a fully automated milling process. PRUFREX is able to make air core coils with wire thicknesses from 0.045 to 1.6 millimetres.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Special mechanical engineering - unique, individual, tailored For the plant, machine and special machine engineering sector, we manufacture ■ custom-made components ■ casings and coverings ■ machinery racks ■ noise-protection cabins ■ complete assemblies Thanks to our vertical integration combined with a large material storages, we are realizing shortest throughput time for your projects on highest quality level. We serve numerous sectors like the rubber industrie, steel processing industry, automation technology, consumer goods industry, energy industry and any other branches where individual steel, stainles steel and aluminium components and assemblies are needed. Whether you want custom-made components or ready mounted and suface-finished overall systems, we do it for you!

Request for a quote

DIETZ GMBH

Germany

Bent wire parts represent a separate part of our production range. Bent parts differ from springs such as extension springs, compression springs and wave springs in terms of how they are produced. This type of spring is not only processed with automated machinery, but also involves a considerable amount of special handling, which we perform using our range of state-of-the-art equipment. Precision production with our high-tech machinery: Our range of machinery with an in-house toolmaking workshop enables three-dimensional bent parts to be produced with a wide variety of forms and with specialised finishes applied to the ends. Our range of machining processes includes: Bevelling, embossing, thread cutting, thread rolling, turning and milling. For bent wire parts, both CNC bending and mould-based bending are possible as production solutions.We process wire thicknesses of 0.20 to 8.00mm.Tool-based: 0.50 to 8.00 mm. Coating of part surfaces: Oiling, Vibratory finishing, Galvanisation.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

An automatic detergent piston filling machine is a piece of equipment that is used to fill detergent products into bottles or containers. This machine operates by using a piston that pulls the product from a holding tank and then dispenses it into the containers. The process is automated, which means that the machine can fill a large number of containers quickly and efficiently. Feature: Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L Hopper: automatic liquid feeding system Container: suitable for 0.5-2L Plastic bottles Voltage: 220VAC 50/60Hz Power: 2000W Drop-proof filling nozzles: adapting vacuum sucking nozzles. Touch Screen Language: English and Chinese

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Test contacts on the circuit board, produced for just this purpose, are contacted by fine, spring-loaded test pins. Depending on the series size, the in-circuit test can take place manually or in an automated fashion. In combination with other test processes, including tests without test contacts, over 90 percent of all errors can be detected.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP drinking water tanks for water supply companies are offered together with our project partner Kurz Leitungsbau GmbH. In doing so, we meet the highest standards applicable to the supply of drinking water, from planning and conception up to construction. Our automated welding process for high alloy stainless steels based on the LIPP System enables us to offer tanks with a maximum volume of 10,000 m3. In addition, on site production “off the production line” enables construction to be completed within the shortest possible time. Optimum quality thanks to automated welding process Material savings and additional stability thanks to circumferential profile Short construction times thanks to mechanised production Easy to maintain and clean Low investment and maintenance costs Can be set up indoors or in the open air Turnkey complete solution or components

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The semicontinuous TFi3000 for industrial use is not a compromise, but rather the combination of the benefits of two entirely different systems! It permits smoke, heat and cold treatments in a single production step. Automated work processes lower your operating costs while at the same time increasing production capacities. Efficient combination of Ti3000 & IKi3000 Production justintime, controllable and reproducible work processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The TF3000 combines the Turbomat T3000 and the intensive cooling system IK3000 in a single closed system. This means one thing most of all Best output per chamber part for the shortest process times. The automated transport system not only reduces operating costs, but also increases production capacities in the system. Maximum output per chamber part Production justintime, controllable and reproducible processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quoteResults for

Process automation - Import exportNumber of results

161 ProductsCountries

- Germany (76)

- France (20)

- Turkey (7)

- Ukraine (7)

- Russia (6)

- United Kingdom (6)

- Spain (5)

- Netherlands (4)

- Switzerland (4)

- Czech Rep. (3)

- South Korea (3)

- Italy (2)

- Lithuania (2)

- Slovenia (2)

- Taiwan R.O.C. (2)

- United States (2)

- Belarus (1)

- Belgium (1)

- China (1)

- Estonia (1)

- Hong Kong (1)

- Japan (1)

- Luxembourg (1)

- Moldova (1)

- Poland (1)

- Thailand (1)

Company type

Category

- Tanks, metal (16)

- Electrical & Electronic Components (7)

- Automation - systems and equipment (6)

- Robotics (6)

- Food - import-export (4)

- Mechanical engineering - custom work (4)

- Food industry packaging machinery (3)

- Pallets (3)

- Sensors (3)

- Software (3)

- Storage equipment and systems (3)

- Business intelligence (2)

- Cartoning machinery (2)

- Cooking and smoke-curing equipment for delicatessens (2)

- Customer relations management software CRM (2)

- Electric and electronic components - machines for manufacturing (2)

- Industrial robots (2)

- Metal detectors (2)

- Metallurgy - machinery and installations (2)

- Palletising machinery (2)