- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pump inspection

Results for

Pump inspection - Import export

TRBA

Belgium

The Sewerage division of TRBA Group specialises in the installation of sewers, collectors, inspection chambers and pumping stations that contribute to the sanitation of both urban and rural areas. These works enable wastewater to flow to the treatment plants designed and built together with our electromechanical partners.

Request for a quote

MAINTENANCE PARTNERS

Belgium

Pump Services Our services range from standard inspections and repairs to complete overhauls. A repair or overhaul of a pump generally consists of an Inspection, Repair/Modification and a final Report. Inspection The first step when repairing any pump is the inspection. Pump inspections include: Visual inspection Measuring axial positions and clearances Disassembly + visual inspection of parts Dimensional measurements Check of probes and sensors (if present) Oil sampling & check When the inspection is finished, an inspection report is drawn up with recommendations for repair. Execution of works After approval of the recommendations for repair, the execution of the repair / overhaul works begins. The scope of work may vary, but can include: Cleaning & steaming Sandblasting Preparation of technical drawings for machining by in-house engineering team Machining of parts (bearing housings, rotors, …) Balancing of rotating parts Coating of rotating parts

Request for a quote

MAINTENANCE PARTNERS

Belgium

Pump Types Maintenance Partners provides services on a broad range of pump types, for example: Vacuum pumps Centrifugal pumps Multi stage pumps Boiler feed pumps Deep well pumps Booster pumps Canned motor pumps Barrel pumps Rotary vane pumps All Brands of Pumps As an independent service provider, we are able to provide services for any brand or manufacturer of pumps, including: ACEC, Alfa Laval, Allweiler, Andritz, Bornemann, Bran + Luebbe, Byron Jackson, David Brown Pumps, DB Union, Dresser, Ebara, Ensival-Moret, Finder, Flowserve, Gardner Denver, Habermann, Hayward Tyler, Herborner, Hermetic, Houttuin, Ingersoll-Rand, Johnson, KSB, lowara, Maag, Metso, Mitsubishi, Nash, Roots, Ruhrpumpen, Sihi, Sterling, Sterling, Stork, Sulzer, Torishima, Victor, Vogel, Vogelsang, Wedapump, Weir, Worthington, … Pump Services Our services range from standard inspections and repairs to complete overhauls. A repair or overhaul of a pump generally consists of an Inspection, Repair/Modification...

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Chemical pump with electrical temperature control. The CHEM series is designed to be easy to maintain. Separate pump covers allow a quick inspection of the inner workings from both sides of the pump. To adjust the axial clearance we use shims which can be varied according to process parameters. Chemical pumps of the CHEM series are offered as standard versions with components made of stainless steel or as special versions with coated or ceramic materials. To bring or maintain the pump at process temperature, two temperature control variants can be used, electric and hydraulic.

Request for a quote

NOKSI METAL

Turkey

Soap and Disinfectant Dispenser Smooth surface, Operated by hand Simple and modern design Smooth mirror surface Standard quality stainless steel for long lasting and performatnce Manually operated by pressing pump Front inspection window Spare parts replacement sold separate Convenient, simple, hygienic, and environmental friendly Useable in hospitals, home, schools, hotels, shopping malls and public used areas

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

14000 - 22000 CFM / 24,000 to 38,000 m³/h Designed to operate in demanding environments such as paper, power, mining and chemical process industries, this pump combines durability and reliability with low operating costs. The P2620 has a polyisoprene-lined body for corrosion and erosion resistance. This is a standard feature. The unique inlet configuration allows for both top and side inlet arrangements to accommodate low headroom installations. Bottom and side discharge connections offer flexibilty to address installation space constraints. The P2620 pump allows efficient operation over the entire vacuum range without the need to change the pump's internals. When equipped with a center shroud, split vacuum operation up to 10 in. Hg (340 millibar) differential can be achieved. Large inspection ports allow easy access to pump internals for inspection and maintenance. Performance ranges from 14,000 to 22,000 CFM (24,000 to 38,000 m³/hr). For more aggressive applications, stainless steel, stainless steel clad and epoxy coated components are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

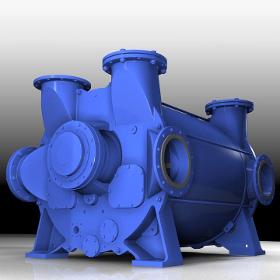

1500 - 19000 CFM / 2,500 to 33,000 m³/hr Nash's 2BE3 & 2BE4 vacuum pump series offers capacities ranging from 1,500 to 19,000 CFM (2,500 to 33,000 m³/hr). Designed to operate in demanding environments like the paper, power, mining and chemical process industries, these pumps offer durability and reliability at a low cost of operation. Each model is equipped with an application-proven polyisoprene-lined body for added corrosion & erosion resistance. The unique inlet configuration allows for both top and side inlet arrangements to accommodate low headroom installations. In installations where space is limited, the top discharge capability of the 2BE4 allows the use of a top mounted discharge separator that saves floor space and eliminates the need for a trench. The pumps allow efficient operation over the entire vacuum range without the need to change the pump's internals. When equipped with a center shroud, split vacuum operation up to 12 in. Hg (400 millibar) differential can be achieved. Large inspection ports allow easy access to pump internals for inspection and maintenance. For more aggressive applications, stainless steel, stainless steel clad and epoxy coated components are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

1500 - 19000 CFM / 3,000 to 9,500 m³/h Nash's 2BE3 and 2BE4 series compressors have capacities ranging from 1,500 to 19,000 CFM (2,500 to 33,000 m³hr). Designed to operate in demanding environments like the paper, power, mining and chemical process industries, these compressors offer durability and reliability at a low cost of operation. Each model is equipped with an application-proven polyisoprene-lined body for added corrosion & erosion resistance. The unique inlet configuration allows for both top and side inlet arrangements to accommodate low headroom installations. In installations where space is limited, the top discharge capability of the 2BE3 and 2BE4 allows the use of a top mounted discharge separator that saves floor space and eliminates the need for a trench. These compressors allow efficient operation over the entire vacuum range without the need to change the compressors's internals. When equipped with a center shroud, split vacuum operation up to 12 in. Hg (400 millibar) differential can be achieved. Large inspection ports allow easy access to pump internals for inspection and maintenance. For more aggressive applications, stainless steel, stainless steel clad and epoxy coated components are available.

Request for a quoteResults for

Pump inspection - Import exportNumber of results

9 ProductsCountries

Company type