- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- confectionery - machinery and equipment

Results for

Confectionery - machinery and equipment - Import export

PKO-SURA COMPANY

Russia

SURA-OM confectionery casting machine for casting sweets fudge in the correction . The machine consists of a moving chain conveyor. The mass from the hopper enters the gear-type dosing head, which performs the casting of sweets into silicone, polycarbonate molds, etc.

Request for a quote

PKO-SURA COMPANY

Russia

The Sura MK and Sura AMK candy forming machines are designed for forming endless bundles, as well as candy cases with and without filling of various shapes in cross-section: rectangular; trapezoidal; semicircular; round, etc. The Sura MK machine is equipped with a guillotine cutting unit, a conveyor and can be connected to glazing machines and cooling tunnels; The Sura AMK machine is used with cooling tunnels and deposits bundles or candy cases on the tunnel tape. For the production of candy cases, the Sura AMK machine is equipped with a string cutting unit.

Request for a quote

PKO-SURA COMPANY

Russia

Starch molding machine is designed for production of fruit-jelly (including jelly candy), liqueur, fondant sweets and Korovka sweets by starch molding. The machine consists of a movable belt, a molding mechanism and a depositor mechanism. The tray is filled with starch which serves as a forming material. The confectionery mass is fed from the hopper to the dosing unit which performs deposition of sweets/molding the marmalade into molds formed in the starch layer.

Request for a quote

PKO-SURA COMPANY

Russia

It is designed for high-quality and uniform coating of various confectionery products with various types of glaze: chocolate fat sugar syrup, etc Due to the tank heating jacket and a mixing device, the glaze is heated to the operating temperature. The glaze is pumped into the glazing tank, and then the tank slide gates are opened and adjusted to obtain a straight, steady stream. The products to be glazed are placed on the feed conveyor and the conveyor is powered up. The products are transported on the large conveyor to the glazing area and then to the blowing area to remove excess glaze from the top. The bottom of the product is smoothed with the special rollers and then the products are transported to the cooling area. The glazing machine can be equipped with a decorator. Products can be glazed separately from the top, bottom or all sides. The machines for glazing with sugar syrup are manufactured considering some modifications necessary to operate the fast-hardening products.

Request for a quote

PKO-SURA COMPANY

Russia

Depositors (extruders) are custom-manufactured depending on the needs of the Customer and the parameters of the oven. All projects are coordinated with the Customer and the oven manufacturers. The machine frame is manufactured in the following types: •U-shaped frame; •frame of intermediate section; •frame mounted in the oven tension station. Mechanisms and units of machines are specially designed considering the increased operating temperature and continuous equipment operation throughout the day. (for making various types of cookies, gingerbread, etc.)

Request for a quote

ALLURE LLC

Russia

A new economical melanger Allure FM5 is a golden key for enthusiasts homes cooking that will open up new possibilities for you. Melanger Allure FM5 will rightfully take its place next to the multi-cooker.

Request for a quote

ALLURE LLC

Russia

Melanger Allure FM1 is a real home cook’s assistant! It is a cute and very easy-to-use device that will easily fit even in a small kitchen.

Request for a quote

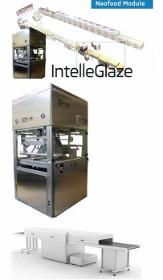

FIS MODULAR SYSTEMS LTD.

Russia

IntelleGlaze is an integral programmable module and can also work as a stand-alone modern glazing and decorating line. In the maximum configuration, it is capable of glazing the product flow divided in half lengthwise in two colors; at the same time, it performs decoration in two other colors. IntelleGlaze glazing equipment includes absolutely everything that is needed for stable, high-quality and reliable glazing and decoration of confectionery and other products for all possible types of glaze, operator actions, and climatic conditions.

Request for a quote

FIS MODULAR SYSTEMS LTD.

Russia

IntelleWaferBall is a wafer balls production line. You can also add variety by changing shapes and sizes (animal figures, filling with boiled condensed milk, creams, etc.). It allows producing products with curd, cheese, salad and pate fillings (salty line).

Request for a quote

FIS MODULAR SYSTEMS LTD.

Russia

IntelleStamp is a modern molding and extruding two-component auger-type complex for molding products from dense masses (toffee, nougat, hematogen, choux pastry for pryaniks, soft nut brittle, chilled dense curd mass) with liquid fillings. It allows you to extrude masses with the addition of particles of 3-5 mm (nuts, raisins, candied fruits, etc.).

Request for a quote

FIS MODULAR SYSTEMS LTD.

Russia

The modern plunger (piston) dosing system for liquid confectionery masses (marmalade, jelly, creams, soufflé, hot chocolate, etc.) supports dot depositing and dotted line depositing. It is designed for depositing or pouring into molds and special hollows in products of liquid food masses. IntelleDrop can be used both as a stand-alone module for filling molds with marmalade, decorating cookies, or injecting profiteroles, and as part of the CreaSweet complex with installation on the IntelleBase module. It comes with a binary gelling section. You can use the machine with rotary ovens (and you still can upgrade it to work with a tunnel oven).

Request for a quote

FIS MODULAR SYSTEMS LTD.

Russia

Modern rolling machine with heated bins for forming two-component products and products filled with a filler made of marshmallows, biscuits, aerated marmalade, soufflé, and other semi-dense masses. It ranges from delicate meringues, soufflés, and marshmallows to dense masses such as qurabiya dough. You can use it to work with minced meat for gastronomic production! IntelleMix performs the functions of dot depositing, dotted line depositing, as well as a continuous extrusion process (marshmallow sticks, cookie sticks, fondant, etc.).

Request for a quote

PKO-SURA COMPANY

Russia

Thermal cooker is intended to make syrup, marmalade, marshmallows, and chocolate glaze. It is designed for the preparation and heating of various confectionery masses: - chocolate glaze; - syrups; - fillings, jams; - marshmallow, marmalade; - scalded dough; - soups, etc. We produce cookers with volume of up to 2000 liters. The frame mixer with scrapers, the DN40 drain valve, temperature sensors for product and heat transfer agent, and heat insulation of cooking container are installed in the factory state. DN60, DN80 or DN100 drain valves are installed according to the Customer's choice. The cookers are equipped with a mechanism of automatic or manual reverse intended to make viscous masses, for example, choux pastry. In this case, the mass is discharged through the neck of the cooker. The reversible and more powerful mixer drive (at least 0.55 kW) is equipped at the bottom. It is possible to install a variable frequency mixer drive for smooth speed change.

Request for a quote

PKO-SURA COMPANY

Russia

The СУРА-СП forming machine is designed for molding sugar cookies onto a belt with a further transportation to a wire-mesh plate of tunnel oven. The forming drum is one of the main units of the forming machine. It is a part of this machine and used for forming one type of cookies that have defined shape and pattern. At the request of the Customer, we can manufacture any number of drums with any pattern and shape of cookies. The patterns and shapes are chosen according to the catalogue.

Request for a quote

PKO-SURA COMPANY

Russia

Highly automated machines is designed for dosing of dough of various shapes and sizes without or with filling from different confectionery products on a baking pan by extrusion: -shortbread dough (hard or soft); -gingerbread dough; -dough for oatmeal cookies; -biscuit dough; -protein mass (souffle sweetmeat, pastille, marshmallow) The two-hopper mechanism of Сура СД and Сура СДУ depositors ensures the dosing of dough for double-color products or single-color filled products. All Сура С, Сура СД, Сура СДУ machines in standard version are equipped with mechanisms for rotation of draw plates and movement of the conveyor in the vertical plane. Сура СДУ universal depositor can be equipped with a diaphragm cutting unit where the diaphragms can be arranged both in single row and in staggered rows. Possibility to equip any Сура С, Сура СД, Сура СДУ machines additionally with a string cutting unit given that the frame of all machine s are equipped with the connection elements.

Request for a quote

PKO-SURA COMPANY

Russia

Cooling of confectionery and bakery products before packaging is one of the most long-run (up to 5 hours or more) processes in production. The conveyor belt with the length of more than 300 m is necessary to transport the products during this time. Сура СKБ spiral conveyor is the best option for a conveyor system for cooling products for a long time. Due to the spiral geometry of the belt arrangement in space, it is possible to provide a large length of the belt in a minimum volume that essentially saves production space. In addition, the product is transported on a spiral conveyor belt as softly as possible, without rolling from one lay to another like in multilayered systems.

Request for a quote

TECHNOPARK IMPULSE LLC

Russia

Cold planers have gained popularity in local road repairs, especially in confined spaces. Impulse cold planers make it possible to use a standard skid steer loader or backhoe loader instead of expensive big cutting machines. And with cold planer and standard loader perfectly perform asphalt works: removing a layer or preparing potholes for repair. Also, it’s used to remove road markings. The design uses standard cutting teeth. • Self-leveling system in a standard supply • Without vibration • Increased teeth life

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Confectionery - machinery and equipment - Import exportNumber of results

17 ProductsCompany type

Category

- Confectionery - machinery and equipment (16)

- Bakery and confectionery industry - machinery and equipment (14)

- Food industry - machinery and equipment (10)

- Bakery - machinery and equipment (9)

- Roadlaying - machinery and equipment (1)

- Building materials, manufacture - machinery and equipment (1)

- Construction machinery (1)