- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coupling

Results for

Coupling - Import export

VR-PLAST, LLC

Russia

Fire intumescent tape in metal case with clip to install on water and sewer pipes. Standart Prof ® fire resistance coupling aimed to retard spreading of fire through water and sewer pipes. Our fire resistance coupling have high protective qualities, developed by our own engineering laboratory. Fire retardant couplings complemented with an aesthetic appearance - the steal case has bright red shell color with an accurate double clip. Packing method: fire resistance coupling in a cardboard box.

Request for a quote

LOOMKNITS (IE NOVIKOV D.V)

Russia

A laconic knitted clutch made of cotton yarn will serve as additional insulation for your hands on a walk. Paired with mittens or gloves, our muff will keep you warm and comfortable even on the coldest day. Decorated with two buttons in the corporate style. It is securely and easily fixed on the stroller handle with Velcro. A soft roller is provided on the handle of the stroller. Lining the most delicate 100% cotton, similar to fleece. Matches perfectly with our envelopes.

Request for a quote

IRIDA LLC (UFANET GROUP)

Russia

Is used for backbone and subscriber FOCL supports as a bracket for an optical distribution box type SNR-FTTH-FDB-24A. This bracket allows storing a cable slack in a coil Ø350 mm in the space between the bracket and the support body.

Request for a quote

VILLINA LLC

Russia

Magnetic couplings are used as transmission mechanisms in modern pumps, which makes it possible to obtain a qualitatively new 100% tight device without making essential changes to the design of the electric drive and the wet end of the pump. At present Villina offers GNVC, GNGC and GNVC-P series vertical, horizontal and semi-submersible centrifugal pumps with magnetic couplings, designed for pumping explosive and flammable, toxic and corrosive fluids (petroleum products, alkalis, acids, alcohols, etc). PURPOSE Magnetic couplings for Villina centrifugal pumps allow for transmission of torque from the electric motor to the pump shaft using magnetic fields generated by permanent magnets instead of mechanical engagement devices. At the same time, there is no need to withdraw the shaft from the pump wet end to the drive device, therefore the wet end can be made in the form of a completely sealed system free of leaks which are typical for pumps with mechanical shaft seals.

Request for a quote

VILLINA LLC

Russia

The magnetic coupling drives for stirring devices are designed to be installed immediately into the tank and provide the necessary stirring of the product. The drive is electrically driven and consists of two half-couplings (driven and driven magnetic half-couplings), bearing assembly and the stirring device itself. Stirring devices (mixers) are of several types: paddle, anchor, propeller, U-type, etc. We develop and supply turn-key solutions for our customers. Magnetic coupling drives for stirring devices are custom-tailored for each specific customer's application in accordance with the sketches provided or according to the parameters specified in the questionnaire form.

Request for a quote

VILLINA LLC

Russia

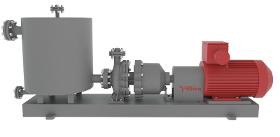

Modern petrochemical and gas industries typically use horizontal centrifugal canned pump units with magnetic couplings similar to Villina-GNGC type pumps. They are designed for transiting neutral, corrosive, toxic, as well as explosive and flammable liquids in stationary conditions, the vapors of which can form explosive mixtures with air. Magnetic coupling pumps combine complete tightness, smooth operation, long service life and high maintainability. A sub-type of horizontal pumping units are high-temperature pumps Temperature of the pumped fluid: -50°C to +420°C; viscosity up to 26 cSt; density 2,000 kg/m3 maximum; mass concentration of solid non-abrasive inclusions up to 0.2%; size 0.2 mm maximum Permanent magnets (SmCo) with an operating temperature of up to 450°C are used for operation in these temperature conditions. The pump, a part of the pumping unit, is a single-stage or multi-stage horizontal centrifugal section-type

Request for a quote

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. However, operation of centrifugal pumps requires building positive pressure (pressure boosting) upstream of the inlet suction pipe for the following reasons: to fill the pump body with the pumped fluid in order to avoid a "dry start" to prevent cavitation during pump operation. Classic methods for creating pressure boosting before centrifugal pumps can be: installation of a tank from which the fluid is pumped, several meters above the axis of the pump shaft and placing the pump in the draw-off sump; inclusion of an additional vacuum pump into the process, which is capable of building the desired pressure boosting of several metres. HOW IS THE PROBLEM OF CREATING A PRESSURE BOOSTING IN MODERN SELF-PRIMING CENTRIFUGAL PUMPS SOLVED? Villina company offers you Villina self-priming GNGC series

Request for a quote

VILLINA LLC

Russia

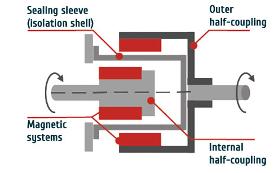

The main parts of magnetic couplings used in GNVC series vertical pumps are the driving (external) and the driven (internal) half couplings, and a sealing sleeve between the half couplings. The exceptional reliability of Villina magnetic couplings is the result of a high-tech design: the enclosed capsular design of the half couplings (enclosed body) secures the magnetic systems from environmental effects; the use of special adhesives allows for fast fixture of domestically produced permanent magnets based on rare-earth elements on the half coupling ferrules; double protection against overheating and demagnetization is implemented using the temperature sensor of the sealing sleeve, which is triggered when the maximum acceptable operating temperature is exceeded by 20 to 50°C, with the use of magnets with Curie point of more than 100°C higher than the maximum acceptable operating fluid temperature; the sealing sleeve made of high-strength Hastelloy alloys

Request for a quote

VILLINA LLC

Russia

Vertical semi-submersible pumps are designed to solve the problem of pumping liquid out of a tank when a part of the pump is within the pumped medium. Pump units are used with the engine speed up to 3,000 rpm. Therefore, the temperature conditions for semi-submersible pumping units are up to 250 degrees. Centrifugal semi-submersible pumps are widely used both in petroleum refining (petroleum and drainage pumps) and the chemical industry, and in the food industry. They are used for transit of various liquids and mixtures including explosive and flammable fluids (oil and gas products, etc.). Semi-submersible pumps are in between surface and submersible units and combine all their advantages, nevertheless, a semi-submersible pump is not designed to carry out specialized tasks for which these two types of units were created. Semi-submersible pumps consist of an electric motor, a working section and immersed sections. The engine is placed on a base plate

Request for a quote

VILLINA LLC

Russia

The Villina GNGC series horizontal canned centrifugal pumps with magnetic couplings are widely used in oil and gas companies of Russia and its neighbouring countries for transit of explosive and flammable, toxic and corrosive fluids. The horizontal arrangement allows the use of a GNGC as a replacement for technically obsolete and physically worn pumps without significantly changing the geometry of the location and pump lines group assembly systems. 100% tightness, structural design in accordance with API 610, 685 (ISO 13709) standards and explosion-proof design of GNGC pumps are approved by design institutes and Rostekhnadzor for use in projects for modernization, reconstruction or construction of new facilities. GNGC horizontal pumps with magnetic couplings provide for axial position of the suction pipe and radial position of the delivery pipe. The motor and pump body are mounted on supports (OH 2 according to API 610), the drive shaft of the motor

Request for a quote

VILLINA LLC

Russia

ADVANTAGES - GNVC-P vertical semi-submersible pumps are developed and manufactured according to individual parameters of the Customer and in compliance with normative documents. - Time of manufacture: 90 days. - Warranty period: 24 months. - Chemical pumps are capable of pumping liquids with viscosity up to 35 cSt, and density up to 2,000 kg/m3. PERFORMANCE SPECIFICATIONS - Purpose: transit of corrosive, toxic, explosive and flammable fluids; - Pump rate ranges: 1 to 55 m3/h; - Head ranges: 5 to 250 m; - Seal type: a magnetic coupling according to API 685 with a sealing sleeve made of Hastelloy alloy (standard version) ensures 100% tightness; - Temperature of the pumped fluid: up to plus 250°С; - Shaft speed: 2,900 rpm; - Structural design: type VS4 according to API 610, vertical type, fixed installation on the container neck on the base plate; - Submergence: 1 to 6 metres, with a length increment of 10 cm for the choice of a specific immersed part length of the pump.

Request for a quote

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. Advantages: the fluid can be taken in at a point lower than the axis of the inlet suction pipe without using a pre-installed vacuum pump. - Purpose: transit of corrosive, toxic, explosive and flammable fluids at insufficient suction pressure; - Pump rate ranges: 0.8 to 450 m3/h; - Head ranges: 3 to 132 m; - Self-priming height (depth): up to 6 metres; - Seal type: magnetic coupling according to API 685 or tandem mechanical seal according to API 682; - Climatic version: for moderate and for moderate and cold climate; - Temperature of the pumped fluid: for GNGC-S, GNGC-S-M up to plus 350°С, for NCG-S up to plus 450°С; - Shaft speed: 1,450 or 2,900 rpm; - Structural design: ОН-2 single-stage back pull-out pump according to API 610 or a single block.

Request for a quote

LLC SMARTSERVICE

Russia

Repair kit for pipelines with all accessories for mounting the sleeve and repairing the pipe. The sleeve fitting is manufactured of solid-woven reinforced fiberglass, made in a unique way, which gives a number of advantages compared to standard fittings: fire resistance, high pressure, corrosion resistance, from 30 years of operation. Scope of fitting application - pipelines, including non-metallic, underground, ground, aboveground and underwater versions, with a diameter of 50 to 1200 mm with a maximum internal working pressure of up to 20 Mpa (200 Bar) for pumping gas, oil, petroleum products and other gaseous and liquid media, operated at temperatures from minus 60°C to plus 180°C. Fittings are used for permanent (major) repairs of through and part-through flaws of pipelines with a maximum internal pressure of not more than 12 MPa. Fittings are used for sealing through flaws (fistulas), for integral repair of pipelines with a pressure of up to 20 MPa. Major repairs.

Request for a quote

LLC SMARTSERVICE

Russia

Repair kit for pipelines with all accessories for mounting the sleeve and repairing the pipe. The sleeve fitting is manufactured of solid-woven reinforced fiberglass, made in a unique way, which gives a number of advantages compared to standard fittings: fire resistance, high pressure, corrosion resistance, from 30 years of operation. Scope of fitting application - pipelines, including non-metallic, underground, ground, aboveground and underwater versions, with a diameter of 50 to 1200 mm with a maximum internal working pressure of up to 20 Mpa (200 Bar) for pumping gas, oil, petroleum products and other gaseous and liquid media, operated at temperatures from minus 60°C to plus 180°C. Fittings are used for permanent (major) repairs of through and part-through flaws of pipelines with a maximum internal pressure of not more than 12 MPa. Fittings are used for sealing through flaws (fistulas), for integral repair of pipelines with a pressure of up to 20 MPa. Major repairs.

Request for a quote

LLC SMARTSERVICE

Russia

Repair kit for pipelines with all accessories for mounting the sleeve and repairing the pipe. The sleeve fitting is manufactured of solid-woven reinforced fiberglass, made in a unique way, which gives a number of advantages compared to standard fittings: fire resistance, high pressure, corrosion resistance, from 30 years of operation. Scope of fitting application - pipelines, including non-metallic, underground, ground, aboveground and underwater versions, with a diameter of 50 to 1200 mm with a maximum internal working pressure of up to 20 Mpa (200 Bar) for pumping gas, oil, petroleum products and other gaseous and liquid media, operated at temperatures from minus 60°C to plus 180°C. Fittings are used for permanent (major) repairs of through and part-through flaws of pipelines with a maximum internal pressure of not more than 12 MPa. Fittings are used for sealing through flaws (fistulas), for integral repair of pipelines with a pressure of up to 20 MPa. Major repairs.

Request for a quote

LLC SMARTSERVICE

Russia

Repair kit for pipelines with all accessories for mounting the sleeve and repairing the pipe. The sleeve fitting is manufactured of solid-woven reinforced fiberglass, made in a unique way, which gives a number of advantages compared to standard fittings: fire resistance, high pressure, corrosion resistance, from 30 years of operation. Scope of fitting application - pipelines, including non-metallic, underground, ground, aboveground and underwater versions, with a diameter of 50 to 1200 mm with a maximum internal working pressure of up to 20 Mpa (200 Bar) for pumping gas, oil, petroleum products and other gaseous and liquid media, operated at temperatures from minus 60°C to plus 180°C. Fittings are used for permanent (major) repairs of through and part-through flaws of pipelines with a maximum internal pressure of not more than 12 MPa. Fittings are used for sealing through flaws (fistulas), for integral repair of pipelines with a pressure of up to 20 MPa. Major repairs.

Request for a quote

LLC SMARTSERVICE

Russia

Repair kit for pipelines with all accessories for mounting the sleeve and repairing the pipe. The sleeve fitting is manufactured of solid-woven reinforced fiberglass, made in a unique way, which gives a number of advantages compared to standard fittings: fire resistance, high pressure, corrosion resistance, from 30 years of operation. Scope of fitting application - pipelines, including non-metallic, underground, ground, aboveground and underwater versions, with a diameter of 50 to 1200 mm with a maximum internal working pressure of up to 20 Mpa (200 Bar) for pumping gas, oil, petroleum products and other gaseous and liquid media, operated at temperatures from minus 60°C to plus 180°C. Fittings are used for permanent (major) repairs of through and part-through flaws of pipelines with a maximum internal pressure of not more than 12 MPa. Fittings are used for sealing through flaws (fistulas), for integral repair of pipelines with a pressure of up to 20 MPa. Major repairs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Coupling - Import exportNumber of results

17 ProductsCountries

Company type