- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sheet metal punching

Results for

Sheet metal punching - Import export

ROKVELAS, UAB

Lithuania

- CNC punching: sheet up to 4mm 1250x3000 mm.

Request for a quote

MVD MACHINERY

Turkey

MVD Turret Punch presses are produced as a closed type rigid steel constructions in to a robust structure to provide minimum deflection during operation. Complete solutions with effective costs.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

J.D. GECK GMBH

Germany

Our competences ,Flexible and toolbased sheet metal processing ,2D laser cutting, punched and folded parts. ,Bent wire parts madetomeasure ,Manual and automated welding. We would be happy to manufacture your preliminary products. More information available at https//www.geck.de

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

When processing sheet metal parts by punching, lasering, plasma cutting, flame cutting, etc., a burr is always created. We have met the challenge of deburring or rounding these “sharp” edges of the workpieces in companies by developing our deburring grinding wheels and deburring rollers. By using these highly flexible tools, both on hand machines and on automatic machines, sheet metal parts can be optimally rounded or deburred. We have the right dimensions for your deburring machine! We would be pleased to advise you on which deburring rollers can be used in your processing, in order to achieve top process results.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Fine blanking is a special processing of precision sheet metal stamping. Including powerful blanking precision blanking, opposing die blanking and flat blanking precision blanking. The geometric shape, dimensional tolerance, shape tolerance and shear surface quality of fine-blanking parts are much higher than those of ordinary blanking parts. Fine-blanking technology plays a very important role in the field of automobile parts manufacturing. There is an essential difference between the process characteristics of fine blanking and ordinary blanking. Normal blanking controls the tearing of the sheet during the blanking process, while fine blanking tries its best to suppress the tearing of the sheet during the blanking. The fine blanking is always kept as one body before the parts are separated from the sheet material, and the metal sheet is always in the plastic deformation process during the fine blanking process.

Request for a quote

GABELLA MACCHINE SPA

Italy

Cut-to-length lines for T-shaped panels Slitting and recoiling lines with automatic separators positioning Dedicated plants for pre-painted,? film-coated or other special materials (stucco-design, mesh, ground surfaces…) Special lines for panels production, with punching, shearing, roll-forming and bending Continuous punching lines Spool recoiling lines De-burring lines Combined lines with partial cut, where a part of the strip is recoiled for future use Machines for mass production or very flexible plants for small productions Cut-to-length and recoiling lines, with coils packaging stations. Customized and very enhanced productions, which integrate the sheet-metal processing with rotating turret punching (possibility of up to 24 different tools? a time, even in “multitools” solutions) or fiber laser cut.

Request for a quote

ADMET SP. Z O. O.

Poland

We offer sheet metal punching for all kinds of materials. We work on AMADA machines. Max width: 3000mm Max thickness: 6mm

Request for a quote

LVD

Belgium

The VX-Series is the choice for production applications demanding high productivity. These full-featured sheet metal punching machines are exceptionally versatile – high hit rates, large feed clearance and powerful control capabilities combine to enable optimal throughput. Full sheet utilization and heavy sheet carrying capacity also add capacity – as do smart features and automation options. It all adds up to punching productivity that is unsurpassed. KEY FEATURES Versatile 48-station thick turret Four programmable 88,9 mm auto index stations Indexable multi-tool capability offers more capacity Three programmable and relocatable work clamps maximize sheet utilization Energy Reduction System minimizes power consumption Quick-change die holders Smart Clamp ensures the smallest possible no-punch zones Smart Stroke automatically optimizes ram stroke Programmable parts removal chute PERFORMANCE-ENHANCING OPTIONS CADMAN-P programming software ABS automatic tool lubrication

Request for a quote

FOXLASER

Bulgaria

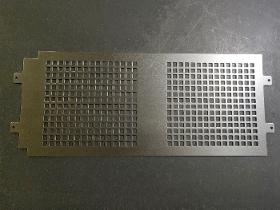

The punching is a preferred technology in cutting-out of galvanized metal sheets. In FoxLaser we have 4 pc. punching machines that enable us to process without repositioning sheet material with dimensions 3000/1500/3mm. The main advantage compared to laser technology is the possibility of cutting and forming of the sheet material. The combination usage of punching and laser cutting allows us to make numerous identical holes (grid) or just forming in a laser cut parts. The biggest advantage in FoxLaser punching are a tripple tooling we have that allows us to produce same time same part in all machines. For achieving maximum performance we work with wide range of functionalities by the well proved softwares SigmaNEST and Metalix CNCKad, in combination with the customized software of the company AMADA.

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Automated punching plants are particularly economical for large quantities, offering excellent process safety. The ECKOLD range of punching machines includes automated punching units as well as portable and hand-held tools, thus catering for virtually any punching task. After a detailed evaluation of your punching task, we devise a solution that is not only economical but also perfectly adapted to match your requirements and workpiece specifications. This offer includes: • Pneumatic punching frame for fixing a cover • Stationary or robot-guided • Round hole, D = 3.5 • Integrated suction nozzle for scraps • Punching inserts • Assembly condition/interfaces: drilling pattern at c-frame • Connectable to cylinder, feed ejectors, initiators Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Other drive types on request. Contact us for a customised offer!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

ECKOLD extrusion embossing allows for direct screwing in sheet metal and does away with press-fitted or welded nuts. The embossed structure formed in the process increases the number of turns for the screw and thus enhances its grip. In addition, extrusion embossing allows for higher torques than would be possible with simple screwing of multiple sheets. The technique is suitable for use in virtually all industries where sheet metal is machined and joined - stationary, robot-controlled or as a punch press system. This offer includes: Servo motor-driven extrusion embossing system • Embossing punching frame, horiz. throat 150 mm stationary or robot-guided • Servo motor-driven Press force approx. 58 kN Working stroke approx. 100 mm • Tool holder • Control cabinet incl. software ECKOLD VISU Embossing inserts are not included in the scope of delivery. Scrap suction/micro spray system on request. Contact us for a customised offer!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Embossing punching is an important technique in the automated production of car parts, guided by robots. A laser system with a sensor harness measures the car body and its machining plane so that the embossing depth can be determined with maximum accuracy. The car body part is then embossed accordingly and all necessary holes are punched. Embossing punching is used for the fixture of headlights, bonnets, sliding roofs, boot lids and locks as well as wings. Our embossing punching machines are suitable for single-layer steel and aluminium sheet metal. This offer includes: • Embossing punching frame (assembly elements or components can be perfectly aligned to a mating part of different dimensions) • Handling: robot-guided via defined interfaces (mechanical, electrical, pneumatic) • Servo motor-driven Tool inserts and measurement are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer!

Request for a quote

HOFFMANN NEOPAC AG

Switzerland

When making round tins, we first print and varnish the metal sheet, which we then punch out and deep-draw. Round tins have a slip lid, which can simply be pulled off, unscrewed or opened by pressing it. Lids are available with a rolling or flat edge. Our specialty round tins include Klipp-Klapp® tins, squeeze top tins, and snap top tins.

Request for a quote

KC KESICI TAKIM

Turkey

CNC turning, CNC milling, CNC bending, CNC finishing, CNC boring, CNC cutting, CNC punching, CNC sheet metal work, CNC tools

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

EPP ENERGY PEAK POWER GMBH

Germany

This flat rate for the proven Alumero substructure for pitched roofs allows you to calculate your offers quickly and easily. Please note that the individual static calculation must be made by us at the latest when you place your order.

Request for a quote

ROKVELAS, UAB

Lithuania

At given need our experts can invoke extensive subcontracting.

Request for a quote

ROKVELAS, UAB

Lithuania

-CNC punching sheet up to 4 mm 1250x3000 (steel); - CNC bending up to 3000 mm (aluminium 5 mm, steel 4 mm).

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

We offer cleanout set. Plumbing cleanout is a cleanout fitting with a removable plug that is found in a roughed-in waste system. It is designed to help keep clear any type of debris that could cause any type of stoppage in the water drain lines. Cleanout sets are usually placed at the connection point between the sewer lines and the drain lines where the base is located of a vertical stack, and at all places were the pipe direction changes at about 90 degrees. Material: Products are available in Stainless Steel AISI 304 (EN 1.4301) / AISI 316 (EN 1.4401 / 1.4404), Chrome plated Brass, Nickel Bronze Sizes: Currently sizes available are 200X200mm, 150X150mm 100X100mm, 80X80mm etc. Special sizes can be made as per your requirement.Finishes: Various finishes are available like MATT, MIRROR, and SATIN Fitment: It slips snugly into the drainage pipe and is easy to install. Cleanouts can be designed to fit various pipes. Designs: Various types of sizes and designs are available.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in Turning Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper

Request for a quote

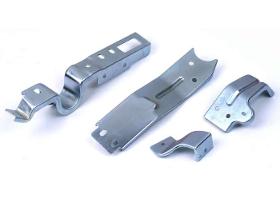

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg is a China manufacturer specialize in sheet metal Stamping services more than 20 years,have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver...

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in sheet metal Stamping services more than 20 years,have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver...

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in sheet metal Fabrication & Stamping services more than 20 years,have been customized many kinds of sheet metal Casing,Enclosure,Bracket,Plate,Decoration Panel for different industries. We providing various processes such as punch Laser cutting,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Sheet Metal Fabrication Products Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishes: Anodize,painting,powder coating,blackening,electroplating of chrome/zinc/nickel /tin/silver... sales@mxmparts.com +86 13780014913

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg is a processional sheet metal Stamping Parts manufacturer from China,have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver... sales@mxmparts.com WhatsApp:+86 13780014913

Request for a quote

CESAL ELEKTRO S.R.O.

Czech Rep.

With its compact dimensions and zero inside turning radius, the Genie® GS™ - 3246 scissor lift is ideal for indoor and outdoor construction, maintenance and installation on level ground and in confined spaces Max. working height 11.75 m Max. basket capacity 318 kg Drive type Battery Own weight 2800kg

Request for a quote

CESAL ELEKTRO S.R.O.

Czech Rep.

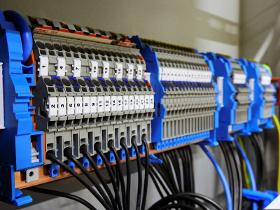

The offer of electrical installation work forms the solid foundation of our company. It is connected with the own production of electrical switchboards. high current and low current installation by installing a lightning rod design activity Production of LV switchgear (without limitation by current value)

Request for a quoteResults for

Sheet metal punching - Import exportNumber of results

58 ProductsCountries

Category

- Sheet metals - stamping (28)

- Sheet Metal & Tubes (7)

- Industrial sheet metal work (4)

- Punching machine tools (3)

- Cutting - steels and metals (2)

- Laser - cutting and welding machines (2)

- Electrical & Electronic Components (1)

- Embossing machine tools (1)

- Grids, metal (1)

- Grinding - steels and metals (1)

- Lifting equipment (1)

- Metal structural work (1)

- Metals - Machines & Equipment (1)

- Perforation of steels and metals (1)

- Steel & Metals (1)