- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sheet metal

Results for

Sheet metal - Import export

METAL IN LTD

Bulgaria

The modern equipment with CNC machines, which we possess allow us to work sheet iron with thickness till 18 mm and dimensions 1500x3000 mm. These products are with high quality, precise manufacturing and excellent external look. Thank to different machines and equipment (lazer cutting, stamp press, punching, shears, eccentric and hydraulic presses, machine shafts, bending machine for metal sheets straightening , spot welding, robotic MIG-MAG welding, WIG welding, powder coating. The company produce big variety of products as the more important are: Hydraulic reservoirs Metal boxes for electronics Wardrobes Cabinets for instruments Metal cabinets for coffee machines Front panels for professional speakers Fireplaces, burners and barbecues Gun safes and storage of documents Control panels for machines Doors and lids for machines and vacuum cleaners Equipment for stores Lamps for lighting Steps of excavators

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We produce tools for sheet metal transformation up to dimensions 3200 x 1800 mm and weight 12 t. We manufacture over-aggressive tools, deep-drawing tools and transfer tools. We produce tools with built-in feed systems with embossed nuts, bolts, pins, bearing bushes and threaded units specially programmed and connected to the press. Everything can be seen in the gallery.

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 1,40 kg Height : 12 cm Width : 100 cm Material: 3 mm

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 0,70 kg Height : 10 cm Width : 100 cm Material: 2 mm

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 0,69 kg Height : 7,5 cm Width : 100 cm Material: 3 mm

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 27,210 kg Height: 99 cm Width: 190 cm Material: 3 mm

Request for a quote

SC PROFINOX SRL

Romania

We offer sheet metal rolling services performed according to the highest standards of precision. With the help of highperformance rolling machines, our specialists will help you turn parts from flat to cylindrical and conical in the shortest possible time. Sheet metal rolling involves cold working of the sheet metal, through which the metal is shaped, taking on curves. The rolling process is essential when manufacturing certain complex products which combine different radii of curvatures. Our rolling services cover both sheet metal rolling and rolling operations for round pipes with a diameter of 20 mm, 40 mm or rectangular pipes of various sizes. For more information about the technical aspects of our rolling services, please contact us by filling in the online form.

Request for a quote

TRIBUNAS & FIGUEIREDO, LDA

Portugal

We offer sheet metal bending services up to 3m. We have high-performance press brakes with 7 axes and up to 160 tons of bending force.

Request for a quote

FATIH WROUGHT IRON

Turkey

30x30 mm - 0,013 kg - 0,8 mm 40x40 mm - 0,018 kg - 0,8 mm 50x50 mm - 0,033 kg - 0,8 mm 60x60 mm - 0,038 kg - 0,8 mm 80x80 mm - 0,061 kg - 0,8 mm 100x100 mm - 0,088 kg - 0,8 mm 120x120 mm - 0,139 kg - 0,8 mm 150x150 mm - 0,200 kg - 0,8 mm 200x200 mm - 0,296 kg

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

Hai Tong focus on sheet metal parts and we are professional sheet metal bender in China, we develop various kinds of sheet metal boxes using blanking, bending, TIG welding, grinding, and powder coating, some sheet metal boxes can be waterproof with IP65.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

As one skilled sheet metal forming manufacturer, Hai Tong serve many industries like medical, aircraft, furniture, architecture, etc with professional metal forming knowledge, and know how to realize your design, for small quantity, we usually laser cut overal shape and NCT bend them quickly, as one sheet metal bender.

Request for a quote

SRL

Italy

The staff of Alaia Serramenti srl also includes a team specialized exclusively in cutting and bending sheet metal. These operations, fundamental in the engineering and metalworking industry, allow us to obtain shapes and geometries of absolute precision and customized down to the smallest detail, depending on the specific application for which they are prepared. The first phase of the process consists of cutting the sheet metal, which is carried out by a specially programmed machine so that pieces of precise dimensions and shapes can be obtained. Bending, the second phase of the process, allows the sheets to be shaped, thus making them more functional for the purpose for which they are modified. Thanks to the latest generation machinery we have at our headquarters in San Cipriano d'Aversa, and the knowledge of our qualified staff, we are able to create sheets of metal with the shapes you desire, adapting them to your needs. Each type of sheet metal

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

This metal stamping casing consist of lower and upper cover with white and black finish, lower and upper casing will be assembled together with screws from the side slot, all electronics components will be fixed on the upper casing with international standard screws, this set of metal casing can stand high temperature during usage, both are formed by metal stamping processes, the lower casing will be TIG welded on four sides, grinded and then powder coated in white.

Request for a quote

EUROWIRE LDA

Portugal

Sale and Rental of: Panels w/ 2 Side Tubes ; Panels with 4 Tubes around Dismountable panels for easy transport and assembly on site with 2 Lateral Tubes And reinforced concrete bases

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RPWORLD

China

RPWORLD offers sheet metal fabrication and pre-assemblies services as the complementary of our one-stop manufacturing service. The core benefits of this process include one-stop service, wide materials selection, hardware inserts, and our extensive experience in applications. - Wide Material Selection Aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum. - Hardware Inserts Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication. - One-stop Service Maintain consistent part quality and guaranteed lead times under our one-stop service. - Rich Experience for Various Applications Auto parts, medical devices, home appliances, robotics, scientific instruments etc. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

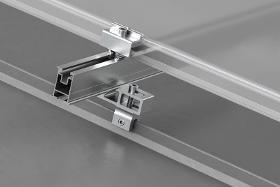

ALUMERO SYSTEMATIC SOLUTIONS GMBH

Austria

Sheet metal folding clamps for a wide variety of folds Simple truss profile mounting due to pre-mounted rapid installation adapter Non-penetrative attachment via fixing screw Tested and statically approved sheet metal fold clamps Module can be mounted vertically or horizontally Designed for roof gradients of 7° to 60°

Request for a quote

EPP ENERGY PEAK POWER GMBH

Germany

With the short rail system from Alumero for trapezoidal sheet metal, module assembly is done quickly and safely. The short version with a length of only 100 mm is ideal for arranging the modules horizontally. By clamping on the long side of the frame, the best possible load capacity of the module is retained.

Request for a quote

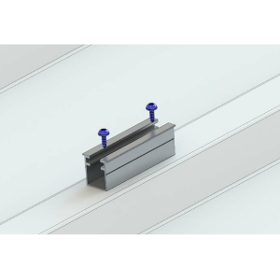

EPP ENERGY PEAK POWER GMBH

Germany

With the Alumero lightweight elevation, you can increase the module inclination by 5 – 7° (depending on the arrangement of the module) with trapezoidal sheet metal roofing. With only a slight roof pitch, this can noticeably increase the yield and the self-cleaning effect of the modules. The increased installation results in larger row spacing. The lightweight trapezoidal sheet elevation is based on a stronger version of the proven Alumero trapezoidal sheet metal rail with a length of 400 mm.

Request for a quote

EPP ENERGY PEAK POWER GMBH

Germany

This flat rate for the proven Alumero substructure for pitched roofs allows you to calculate your offers quickly and easily. Please note that the individual static calculation must be made by us at the latest when you place your order.

Request for a quote

RPWORLD

China

RPWORLD offers sheet metal fabrication and pre-assemblies services as the complementary of our one-stop manufacturing service. The core benefits of this process include one-stop service, wide materials selection, hardware inserts, and our extensive experience in applications. - Wide Material Selection Aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum. - Hardware Inserts Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication. - One-stop Service Maintain consistent part quality and guaranteed lead times under our one-stop service. - Rich Experience for Various Applications Auto parts, medical devices, home appliances, robotics, scientific instruments etc. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

ILK IHRACAT AS.

Turkey

Applications of Carbon Steel Sheets The applications of carbon steel sheets are quite extensive. Here are some examples: Construction: Carbon steel sheets are widely used in large construction projects for structural frames, bridges, and more. Automotive Industry: They are employed in the automotive industry for chassis and body components. Maritime: Due to their resistance to seawater, carbon steel sheets are used in shipbuilding. Power Plants: Carbon steel sheets serve as durable coating materials in power plants, withstanding high temperatures and pressures. Advantages of Carbon Steel Sheets Carbon steel sheets offer several advantages: Cost Efficiency: They are more cost-effective compared to other materials. High Strength: Carbon steel sheets have the capacity to withstand heavy loads. Wide Range of Applications: They are adaptable to various applications across different industries. Contact Us for your sheet metal needs.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Custom metal stamping parts FRIMA is the professional custom metal stamping parts manfacutrer. During the metal stamping process, blanks or coils of sheet metal feed through one or more die and tool sets. These die and tool sets form and cut the sheet metal into its desired shape.

Request for a quote

AEROLIFT INDUSTRIALS B.V.

Netherlands

Sheet metal handling and lifting steel plates with vacuum technology. Both magnetic and non-magnetic sheets are easily lifted. The suction pad is placed on the metal product, after which the vacuum is activated by a push on the button. Now you can lift, move, or even turn the sheet metal. Vacuum lifting is used during production, storage, internal transport, transhipment, and construction. Besides vacuum lifters for metal plates, we also design pipe handling equipment. All our designs are custom made to perfectly match the individual situation. Why choose lifting plates by vacuum? Vacuum offers unique advantages compared to other lifting methods to lift plates, such as chains, clamps, and magnets. Chains and clamps can be used to lift non-magnetic plates, such as aluminium, copper, and stainless steel. Compared to these lifting methods, vacuum offers distinct advantages: No damage to the plate, not even scratches No spacers or stoppers required Easy and fast handling Less manpower

Request for a quote

ELEKTRON SP. Z O.O.

Poland

“Bending” is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in plastic materials, most commonly sheet metal. Commonly used equipment includes box and cup brakes, press brakes, and other specialised machine presses. Typical products that are produced in this way are boxes, such as electrical enclosures and rectangular ducts. Bending sheet steel The combination of modern presses, advanced matrix, stamps and the experience of our employees provides excellent results in the form of professionally performed artistic processing of various sheets. We bend sheets quickly and extremely precisely, and thanks to the fact that the process is fully repeatable and automatic, we can undertake even very large orders. The maximum pressure of our machines is as much as 200 tons, thanks to which we can undertake artistic processing of materials with a thickness of 6 mm over a length of 3 meters.

Request for a quote

COSTRUZIONI METALMECCANICHE VALENTE

Italy

At our Nole plant we have an architectural and structural metalwork department where multiple operations are performed. Our ability to work different materials (common and alloy steel, stainless steel, aluminum etc) and the machinery we use combine to make our company a leader in the industry. In particular, we deal with: Sheet metal processing: shearing, press-bending, calandering, drilling and notching; Welding and joining of different materials in TIG, arc, and continuous wire modes; Construction and installation of several different types of metal structures, using tubular materials, profiles, beams and semi-finished parts;

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HCS 90 E model represents a complete system package specifically designed for steel sawing applications in a variety of industries. This model offers a highly cost-effective solution that was designed using the latest technology available such as an automatic circular cold saw, a loading magazine and the chip conveyor. The machine has a sturdy and robust base frame on which the combined sawing unit and material feed unit are mounted. This structure combined with a very robust machine design ensures a smooth sawing process with excellent cutting results and a long service-life of the saw blade. And what is remarkable: This system concept covers a large range of all industrial requirements, providing the highest quality at an unbeatable priceperformance ratio. The HCS 90 E is the ideal cold saw for solid material and tubes up to a diameter of 90 mm. Loading of rectangular profiles up to 65 mm with the magazine is an available option.

Request for a quoteResults for

Sheet metal - Import exportNumber of results

613 ProductsCountries

- Germany (142)

- Turkey (119)

- China (96)

- Slovenia (35)

- United Kingdom (27)

- Portugal (26)

- Poland (22)

- Netherlands (20)

- India (14)

- Bulgaria (13)

- Taiwan R.O.C. (13)

- United States (11)

- Romania (10)

- Czech Rep. (8)

- Slovakia (7)

- Italy (6)

- Ukraine (6)

- France (5)

- Serbia (5)

- Spain (5)

- North Macedonia (4)

- Austria (3)

- Belarus (3)

- Hungary (3)

- Canada (2)

- Ireland (2)

- Australia (1)

- Cyprus (1)

- Lithuania (1)

- Russia (1)

- Switzerland (1)

- United Arab Emirates (1)

Company type

Category

- Industrial sheet metal work (150)

- Sheet metals - stamping (128)

- Profiled sheets - ferrous metal (53)

- Sheet Metal & Tubes (51)

- Sheet metal and strips, tinplate (47)

- Milling - steels and metals (24)

- Bending - steels and metals (20)

- Steels and metals - forming and cutting (18)

- Cutting - steels and metals (17)

- Forming - steels and metals (17)

- Astronomy - instruments and equipment (15)

- Laser - cutting and welding machines (8)

- Metal straightening machines (8)

- Rolled sheets - non-ferrous metal (8)

- Electrical & Electronic Components (7)

- Finished Metal Products (6)

- Metal industrial presses (6)

- Welding work - steels and metal (6)

- Coupling screws (5)

- Galvanization - steels and metals (5)