- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sintered metals

Results for

Sintered metals - Import export

BORNEMANN GMBH

Germany

Machine dies made from sinter metal that achieve a hardness of 68 to 70 HRC are a speciality of ours. With these dies, materials with a surface hardness of up to 48 HRC can be labelled. By using a complex production method and a special hardening, special options of use in labelling are achieved for these unique hard dies. The dies are produced to customer drawing or data.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

In some cases, metal powders can be easily made of separate metal parts. Powders are used to create floor and building structures, as well as for surfacing. Their application is possible in engineering, nanotechnology, metallurgy, aviation and industrial industry. At our site, you can order production of sintered powder parts. In this article, you will learn about the basic methods of obtaining metal powders. Parts made of sintered metal. Methods for obtaining metal powders are divided into two types: mechanical and physico-chemical. Mechanical methods are more common way to produce metal powders. For this purpose, special devices are used. It is especially advantageous to use this method in the manufacture of powders of beryllium, antimony or chromium.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

We provide the powder metallurgy manufacturing with a wide range of advantages for our clients: Excellent surface finishes Excellent tolerance control Cost-effective processing Inexpensive materials A wider variety of alloys to use A high-quality end products Machining minimization while producing parts Controlled porosity for self-lubrication or filtration Materials that can be heat-treated Our production line provides manufacturing Sintered parts for suspension, Sintered parts for oil pumps, Sintered parts for engine, Sintered parts for start motors, Sintered parts for transmission and other custom parts according to your drawings.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Currently, production of the parts from mixed metallic powders is slowly displacing traditional casting and stamping. It is happening because this method is different with its speed and cost efficiency. Wastes from the metal-parts production can be used to produce powders. Parts, produced by this method, have high durability and wear-resistance. Sintering allows to receive parts with precise geometric forms. Parts don’t require further machining. Technology of production of sintering suggests putting metal powders into special forms. They are thermal treated in the gas environment, that allows to increase plasticity of material and also add special polymers. Then, parts are being pressed, rolled and formed. During those processes, parts of the metal powders are strongly melted with each other, creating a monolith mass. In order to provide parts with hardness and wear-resistance, they are being thermal treated in special furnaces. More info https://eurobalt.

Request for a quote

BORNEMANN GMBH

Germany

For hard castings, we offer manual dies made from sinter metal. Sinter metal dies are characterised by a hardness of 68 to 70 HRC. With these dies, welded or processes hard surfaces can be labelled. Company logos as well as individual numbers and letters can be provided. The maximum font size should not exceed 10 mm.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase performance of your pneumatic systems Powering pneumatic machines requires clean and conditioned air or gas. Our pneumatic filters are designed to work together with regulators and lubricators (FRL units), to offer outstanding performance and a lower-cost alternative to traditional sintered-metal filters. Specifically designed to provide an excellent combination of particulate filtration, air flow and back pressure performance, while complying with strength and aesthetic requirements, these single-component molded filters: Meet your filtration requirements – Optimized design meets filtration, airflow and pressure drop requirements. Reduce costs – Sintered polymer filters are more cost-effective than sintered metal. Improve machine longevity – Design is optimized for reliability, efficiency and longevity of pneumatic machinery. Features Work together with regulators and lubricators (FRL units) to deliver clean and conditioned compressed air or gas Strong and rigid for...

Request for a quoteFAUDI GMBH

Germany

Advantages Each filter element is individual back blown for a good cleaning effet Area of application Self-cleaning filter for the filtration of gases Flow rate Various filter sizes and the modular design enable any required flow rate. classification number F35 Filter aid - Filtration degree 0,5 - 10 µm Medium Nitrogene, gases Filter material Sinter-metal Cartridges, CrNi-Steel Cartridges

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For sliding properties improvement of machine parts, apparates and precision machinery, especially for microfinished surfaces For incorporation in plastics, sealings, packages, sintered metals and improvement of sliding properties For long-term or possibly lifetime-lubrication Advantages and benefits Reduces friction and wear in a wide temperature range High effectiveness due to high affinity of MoS₂ to metals Low friction at highest load capacities Low consumption based on forming of extreme thin sliding films Not electrically conducting and not magnetic Chemically stable except against halogenated gases, concentrated sulphuric- and nitric acid For best adhesion, clean sliding surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Spray on evenly thin from 15-20 cm distance to the sliding surfaces.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For sliding properties improvement of machine parts, apparates and precision machinery, especially for microfinished surfaces For incorporation in plastics, sealings, packages, sintered metals and improvement of sliding properties For long-term or possibly lifetime-lubrication Advantages and benefits Reduces friction and wear in a wide temperature range High effectiveness due to high affinity of MoS₂ to metals Low friction at highest load capacities Low consumption based on forming of extreme thin sliding films Not electrically conducting and not magnetic Chemically stable except against halogenated gases, concentrated sulphuric- and nitric acidFor best adhesion, clean sliding surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply on small parts in series production by tumbling, under addition of small amounts powder and tumbling parts, until a complete MoS₂ film is formed. Brush the powder onto bigger surfaces.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For sliding properties improvement of machine parts, apparates and precision machinery, e.g. under the influence of oxygen, in vacuum or radioactive radiation Dry lubrication for tools or workpieces in cold- and thermoforming For incorporation in plastics, sealings, packages, sintered metals and improvement of sliding properties For long-term or possibly lifetime-lubrication Advantages and benefits Reduces friction and wear in a wide temperature range High effectiveness due to high affinity of MoS₂ to metals Low friction at highest load capacities Low consumption based on forming of extreme thin sliding films Not electrically conducting and not magnetic Chemically stable except against halogenated gases, concentrated sulfuric- and nitric acidFor best adhesion, clean sliding surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply on small parts in series production by tumbling, under addition of small amounts powder and tumbling

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Potentiometric position transducer with very compact dimensions; robust design with metal flanges; sintered bronze plain bearing; long life span and high adjustement speed; easy to assemble via sliding metal mounting clamps; High protection class

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Potentiometric position transducer with very compact dimensions; robust design with metal flanges; sintered bronze plain bearing; long life span and high adjustement speed; easy to assemble via low-backlash pivot heads with a large angle of freedom; High protection class

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

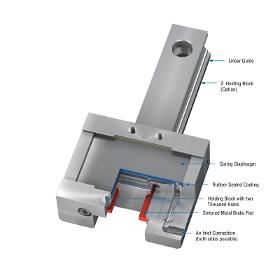

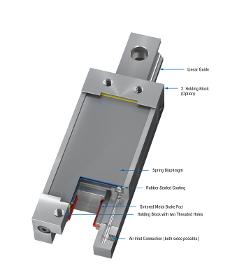

Safety Clamping for Rail Systems, Compact Holding force 300 N Small can clamp perfectly too: The LOCKED-Family SLK clamping elements are more compact than the Series SL. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and safe. Thanks to the patented spring steel plate system, the product family SLK achieves clamping and holding forces of up to 2,100 N with the shortest reaction times when vented. Thanks to the sintered metal coatings and the clamping function in emergency stop (e.g. in case of a power failure), this range enables braking directly on the rail. All clamping elements offer the maximum holding and braking forces and achieve up to 1 million clamping cycles or up to a maximum of 500 emergency braking operations in the 4 and 6 bar version.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Safety Clamping for Rail Systems Holding force 540 N Always on the safe side: The safety clamping elements LOCKED SL clamp and brake directly on the clear area of guide rails on linear modules with forces of up to 10,000 N. They are individually adjusted to the linear guide being used and are available for all rail sizes from 20 to 65 mm and profiles from all renowned manufacturers. Special brake pads made of low wear sintered metal are used for the additional emergency stop braking functions in the safety clamping elements LOCKED SL. The SL product family offers optimum static clamping with a service life up to 1 million cycles or up to 500 emergency braking operations. They also offer low system costs in comparison with hydraulic and electric solutions.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing /Innovacera Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing. Applications: Electrical transmission and distribution Electronics industry Textile machinery Defense Medical electronics Automobile industry Sealing Solid Oxide Fuel Cells High temperature application

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EUROBALT ENGINEERING OÜ

Estonia

Our production line can produce all base sintered parts for shock absorbers manufacturing. Usually for the manufacture of shock absorber parts we use metal powders Sint C10 and Sint C11, this is the basic material for the production of such parts. Also we can use the material according to your requirements.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Metal die casting – is a production technology of castings, in which the alloy under pressure up to 700 MPa quickly fills the mold. Products made in this way can be of different sizes and have weigh up to several kilograms. As a basic raw material normally are used following: non-ferrous metals — copper, aluminum, and their alloys. Die casting makes it possible to obtain high-precision products (along with such technology as powder metallurgy, which allows to obtain sintered metal parts that are particularly hard and wear-resistant). Our company offers the manufacture of parts for LED lighting and other high quality castings. One of the main advantages of die casting is the resistance of finished products to corrosion. The fact is that in the process of their manufacture a strong surface crust is formed, which has a high density and low moisture permeability.

Request for a quote

ALSEN SERVICES LDA.

Portugal

Welded in position PB 2F, MIG-MAG in a passageway of INOX and iron. The boiler is welded with a part of stainless steel pipe and a part of metal pipe according to all standards and requirements for this type of MIG-MAG welding work.

Request for a quote

GGB FRANCE

France

Can be used with different bearing housing materials, e.g. aluminium, magnesium and plastic Feasible for a larger variety of bearing housing dimensions, from thin metal sheet housings up to multiple and sectional longer housing areas Reduced total system costs with increased bearing housing tolerances, even stamped or laser burned housings are suitable Manual and automated installation possible

Request for a quote

MAXON MOTOR AG

Switzerland

maxon X drives Configure the next generation of DC drives. Configure and combine the DC motor (DCX, DC-max), gearbox (GPX) and sensor (ENX) according to your individual requirements, easily and online. After only 11 working days, the drive systems are ready for shipment from Switzerland. Detailed product data can be viewed online immediately and 3D data for the configuration is available for download. An advantage with any configuration. Client showcase - Oxford Space System Oxford Space Systems is an award-winning space technology business developing a range of its deployable structures for space. Oxford Space Systems (OSS), based at the UK’s Space Cluster, on the Harwell Science & Innovation Campus, are a small company with big ideas. They have developed a new type of advanced material, which enables deployable space structures to be uniquely lightweight and allows greater simplicity in design. They have partnered with RAL Space and are able to simulate conditions in space using their thermal vacuum chamber and vibration table. Watch this video to see how OSS are using the popular DCX motor product range from maxon and how Mike Lawton, Founder and CEO, sees the future of the space industry. Watch this 3 minute video to find out how they are working with maxon motor.Configure Ø 16 and 22 mm sizes. Choose between graphite and precious metal brushes, sintered and ball bearings, and many other components.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The AccuCarb® Ceramic Probe is a high accuracy zirconia oxygen sensor designed for the heat treating industry. AccuCarb® Ceramic Probe is a patented, ceramic sheathed probe, high temperature probe, specifically designed for generator and for metal sintering applications. The standard model has an integral type K thermocouple and a tube fitting for air purge burnout of soot.

Request for a quote

3D PROTOTIPAI

Lithuania

For metal printing we are using special technology - Direct Metal Laser Sintering. DMLS is an additive process, when laser melts fine metal powder and builds up the product layer by layer. This method is perfect solution for direct, cost-efficient manufacturing of high-quality metal tool inserts, prototypes and end-use products. DMLS is used when strenght and funcionality of the product is very important. Technology allows tocreate products with extremely complex geometries including elements such as free-form surfaces, deep slots and coolant ducts. DMLS technology is widely used in healthcare, automotive and aviation industries. Choosing different materials produces products with different characteristics such as flexibility, rigidity and durability.

Request for a quote

3D PROTOTIPAI

Lithuania

For metal printing we are using special technology - Direct Metal Laser Sintering. DMLS is an additive process, when laser melts fine metal powder and builds up the product layer by layer. This method is perfect solution for direct, cost-efficient manufacturing of high-quality metal tool inserts, prototypes and end-use products. DMLS is used when strenght and funcionality of the product is very important. Technology allows tocreate products with extremely complex geometries including elements such as free-form surfaces, deep slots and coolant ducts. DMLS technology is widely used in healthcare, automotive and aviation industries. Choosing different materials produces products with different characteristics such as flexibility, rigidity and durability.

Request for a quote

3D PROTOTIPAI

Lithuania

For metal printing we are using special technology - Direct Metal Laser Sintering. DMLS is an additive process, when laser melts fine metal powder and builds up the product layer by layer. This method is perfect solution for direct, cost-efficient manufacturing of high-quality metal tool inserts, prototypes and end-use products. DMLS is used when strenght and funcionality of the product is very important. Technology allows tocreate products with extremely complex geometries including elements such as free-form surfaces, deep slots and coolant ducts. DMLS technology is widely used in healthcare, automotive and aviation industries. Choosing different materials produces products with different characteristics such as flexibility, rigidity and durability.

Request for a quote

3D PROTOTIPAI

Lithuania

For metal printing we are using special technology - Direct Metal Laser Sintering. DMLS is an additive process, when laser melts fine metal powder and builds up the product layer by layer. This method is perfect solution for direct, cost-efficient manufacturing of high-quality metal tool inserts, prototypes and end-use products. DMLS is used when strenght and funcionality of the product is very important. Technology allows tocreate products with extremely complex geometries including elements such as free-form surfaces, deep slots and coolant ducts. DMLS technology is widely used in healthcare, automotive and aviation industries. Choosing different materials produces products with different characteristics such as flexibility, rigidity and durability.

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

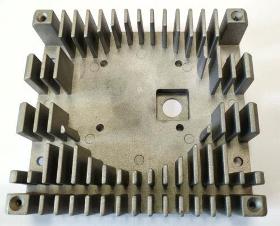

Component for Filter Dryers The multilayer filter plates are supplied according to material requirements and permeability: Fabric (cotton, polypropylene, etc.) Filter elements made from metal Sintered plates Multi-layered plates, sintered Sterile configuration, filter elements are secured from below The existing filter plates for filter dryers can be replaced smoothly and quickly anywhere. This is also possible for machines from other suppliers. According to the customer´s requirement and machine specification the replacement of multilayer filter plates is done completely or separated in different sectors. Multilayers are available in SS 316L or Hastelloy C22 or other materials on request, available porosities 5, 10, 20 or 40 micron, other porosities on request. For machines with a bigger diameter – mainly for chemical specification – the division in different sectors offers, in case of break, the advantage that only the damaged part has to be replaced. This guarantees an...

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our filter grade powders are available in a wide range of particle size distributions and are uniquely suited to produce sintered porous metal filters for demanding applications. Typical materials include a wide number of commercial alloys specifically tailored for filter applications. The alloys available include but are not limited to high performance Stainless Steels, Hastelloys®, Monels®, Inconels® and Nickel. We produce these alloys specifically for sintered filters in tightly controlled size distributions within the 10-250µm range for liquid and gas filtration. We routinely produce more than 25 different sizes of filter product and are happy to take on the challenge of exacting, custom specifications. Filter Powder Expertise We manufacture filter grade powders that are specially atomized to give the highly irregular shape required for precise filtration. Our plant has been producing water atomized powders for sintered

Request for a quoteResults for

Sintered metals - Import exportNumber of results

40 ProductsCountries

Category

- Sintering - steels and metals (8)

- Metal powders (4)

- Silicones (3)

- Ceramics, industrial (2)

- Construction machinery (1)

- Cutting - machine tools (1)

- Die casting moulds (1)

- Heat treatment furnaces (1)

- Metallurgy - machinery and installations (1)

- Sintering machine tools (1)

- Steels and metals - machining (1)

- Transmission elements (1)