- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special mechanical engineering

Results for

Special mechanical engineering - Import export

SIM AUTOMATION GMBH

Germany

Small parts in large quantities? Electrical engineering in particular requires very quick machines. Electrical engineering is also becoming increasingly important in IT, with particularly small components required here. The machines from SIM Automation GmbH can detect even the smallest deviations of mere millimeters during sorting. We have produced assembly and testing lines for the following components in electrical engineering (extract): - Instrument components - Step motors and servo motors - Quick-release clutch systems - Gearbox balance shafts (for checking run-out accuracy and backlash) Assembly lines: - Plug contacts (vehicle electrical systems) - Industrial sockets and switches - Sockets / light switches - Electric heater control valves - Electric razors - Electric toothbrushes Testing and inspection: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quote

SIM AUTOMATION GMBH

Germany

SIM Automation, your partner in - IV catheters - dialyzers - drip chambers - lab-on-a-chip systems, used for various diagnostic analyses and processes in the laboratory on a single chip Assembly and inspection plants in medical engineering that we have been involved in: - Fiber and panel membrane filters - Syringe and infusion systems - Tablet storage and packaging - Flacons / Flacon caps - Lipstick and mascara containers - Coronary testers / rapid blood tests - Sterile caps / membrane seal systems - Components for inhalers - Surgical disposable razors Testing and inspection lines for: - Pacemakers - Dialysis filters Hygienic design is also important here. Back in 2008, we established a clean room in line with Class C / ISO Class 7 requirements in our manufacturing facilities specially for this application area.

Request for a quote

SIM AUTOMATION GMBH

Germany

SIM feeding and sorting systems ensure the reliability of our assembly, testing and inspection systems. We develop, design, manufacture and adapt these systems based on customer specifications and the existing assembly system. A combination of various feeding, handling, camera and sensor systems, robots can be used in additional to individual systems. The systems are used in virtually all industrial branches, including medical engineering, pharmaceuticals, food and cosmetics, the automotive industry and electrical engineering. Feeding systems are an important part of automation technology, as are the isolation and provision of individual components. In addition to simple feeding systems, complex testing, measuring and assembly processes can be added without any problems. Different feeding systems can also be combined thanks to the use of robots and handling systems. In this way, we create a seamless transition from simple part feeding through to compact feeding and testing cells.

Request for a quote

SIM AUTOMATION GMBH

Germany

SIM Automation, your partner in - autonomous driving - electromobility - connected car - electric pumps - operating elements - door locks - instruments - airbag inflators and igniters - gearboxes Development of part-feeding systems and test systems. Assembly and inspections lines that we've already developed: - Airbag inflators - Intercoolers - Oil pumps - Door and trunk locks - Instrument components - Vehicle components for driver assistance systems - Step motors and servo motors - Quick-release clutch systems - Gearbox balance shafts (for checking run-out accuracy and backlash) Assembly lines we have been involved in: - Lighting components (H7 / Xenon / LED) - Safety belt height adjuster - Heatable windscreen washer jets Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quote

SIM AUTOMATION GMBH

Germany

The product portfolio at SIM Automation ranges from the effective design of individual manual workstations all the way through to completely interlinked, highly automated process lines. We handle all common transfer systems and can thus offer solutions that are independent from the branches of our customers. In addition to all standardized joining, measuring, testing and inspection systems, our assembly plants can also implement the customer’s own processes, including: - Joining, screwing, bonding, riveting, welding (laser, ultrasonic, resistance) - Testing, measuring, inspecting (optical, tactile, electrical, thermal) - Robot systems - Linear systems (pneumatic, electrical, mechanical) - Cam-controlled drives, linear and handling systems Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quote

SIM AUTOMATION GMBH

Germany

Lightweight composites and composite materials offer substantial benefits in aviation – above all, they are lightweight yet also safe and cost-effective. Whether large engine parts or smaller components, all are very important when it comes to safety. Both must then be assembled using extremely reliable and precise machines – which is one of the core skills at SIM Automation GmbH. Whether supplier codes, components, serial numbers, approvals or manufacturing dates, suppliers in the aviation industry handle complex assemblies with a great deal of data that has to be recorded. You have the option of managing traceability via a work instruction or by using a laser cell from SIM Automation GmbH. Laser marking cells realized by us for the marking of: - Combustion chambers - nameplates

Request for a quote

ULBRICH GMBH

Germany

Picture 1 Prvoted bogy test stand Picture 2 Press tool to press the bearing cup into the bogie Picture 3 Spring tester with supply line on both sides Picture 4 Test press to test the fitting of the whell disc Picture 5 Test stand for design material developement on bogies wit 16 hydraulic axis

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Durable with high operational reliability. Powerful. Design features: • robust construction • automatic product feeding • Vacuum box extraction • Product-dependent carton suction • Carton erection in the chain • All-round product inserters • Main shaft drive • Frequency controlled three-phase drive • encapsulated gearbox • automatic chain tensioner • all product-carrying components made of stainless steel • Fast format adjustment • Gas pressure spring-loaded protective doors made from Makrolon • PLC control Additional devices: • Hot glue seal • Combined hot glue and plug closure • Special plug lock • Cardboard storage tapes with automatic magazine loading • Embossed printer for signing a flap • Coding (inkjet / laser), blind embossing • Code reader with or without folding box ejection device • Equalization for powdery or granulated products • Upper runner to support the insert easily deformable products • Inserts for brochures booklets, spoons etc.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Special cylinders developed and manufactured according to individual customer requirements, specifications or specifications. Both as a completely custom-made special cylinder or modified inexpensively using standard elements with adjustments in form, function, mount, connection or material.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Special mechanical engineering - unique, individual, tailored For the plant, machine and special machine engineering sector, we manufacture ■ custom-made components ■ casings and coverings ■ machinery racks ■ noise-protection cabins ■ complete assemblies Thanks to our vertical integration combined with a large material storages, we are realizing shortest throughput time for your projects on highest quality level. We serve numerous sectors like the rubber industrie, steel processing industry, automation technology, consumer goods industry, energy industry and any other branches where individual steel, stainles steel and aluminium components and assemblies are needed. Whether you want custom-made components or ready mounted and suface-finished overall systems, we do it for you!

Request for a quote

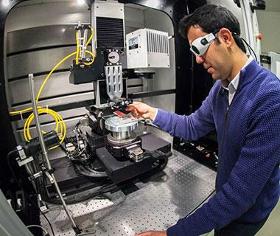

FÖHRENBACH GMBH

Germany

A lever clamping permits a simple, fast and exact adjusting of different working levels, without any efforts to adapt the devices. The swivel unit is available for the rotary tables RT2A075, RT2A100, RT2A150 und RT2A200. Field of applications: Assembly technologies, measuring and testing equipments, laser writing, welding, cutting, as well as special mechanical engineering. Features (RT2A100, RT2A200): Individually adjustable swiveling range from -5° to +95°. Fixed stop iin the 0° and 90°. Other positions possible by customer request. Clamp and locking effect through laterally installed, adjustable clamping lever. On one side appropriate scaling in 1° steps. Fixing of the swivel unit through four countersinking holes in the base plate.

Request for a quote

ULBRICH GMBH

Germany

Test machine for life time test, wearing quality, bending resitance and slippage on wire ropes.

ULBRICH GMBH

Germany

Assembly press with 3 small rotary table mounted in a big rotary table

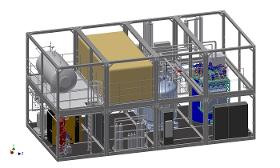

ULBRICH GMBH

Germany

Autofrettage system for pressure applications on radiators, pumps etc.

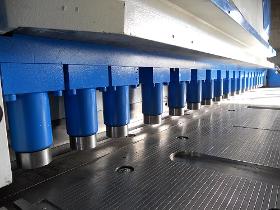

ULBRICH GMBH

Germany

Hydraulic press with 12 acting cylinder, force and distance controlled

Do you sell or make similar products?

Sign up to europages and have your products listed

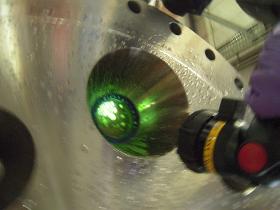

STEEC

France

Wire spark erosion, laser micro-cutting, micro-milling and micro-drilling STEEC is also involved, both as a subcontractor to numerous SMEs and agencies in the metallurgy and mechanical engineering sectors which very often engage in subcontracting activities themselves. STEEC enables these players to respond to invitations to tender that involve meeting precision micro-machining requirements for which they are not equipped. The wide variety of precision micro-machining operations which STEEC offers is highly beneficial to these SMEs and agencies, which are able to offer a comprehensive service in micro spark erosion, laser micro-cutting, micro-drilling and milling.

Request for a quote

KASAG SWISS AG

Switzerland

KASAG undertakes cutting, forming and welding works for manufacturing simple and complex welding constructions of up to a weight of 13 t in stainless steel and aluminium. Our specialists have been certified according to ISO 3834-2 in all required welding processes MIG, MAG, TIG, plasma and orbital.

Request for a quote

KASAG SWISS AG

Switzerland

We have many years of experience in grinding and brushing of stainless steel surfaces for all object forms, as well as in the manual and machine grinding of circular objects. Our combined grinding machine/plant can be universally used, owing to its modular construction; it is of premium quality and guarantees surface roughness for stainless steel surfaces, on the inside and the outside for cylinders, spherical heads and cones for grinding welding seams superelevations for grinding longitudinal and circular welding seams roots

Request for a quote

KASAG SWISS AG

Switzerland

KASAG has many years of experience in staining and passivating stainless steel and aluminium alloys. Our services for single objects are invoiced according to the expense and effort invested, or in the case of larger objects, according to prior quotation. For serial parts, the unit price is taken as the basis for invoicing. Bath pickling: 1,900 x 900 x 800 mm Sprays pickling: 6,000 x 3,000 x 2,500 mm (max. object size)

Request for a quote

KASAG SWISS AG

Switzerland

With our highly modern 3D plasma cutting equipment, we undertake plasma cuts of spherical bottoms/heads, dished boiler heads, pipes, profiles and metal sheets in material thickness of 1 - 50 mm. Metal sheet change:2,000 x 3,000 mm (2,000 x 6,000 mm) Pipes, profile:diameter 30 - 500 mm / length 3,000 mm (6,000 mm) Heads, cones: up to diameter 2,500 mm Material thickness:1 - 50 mm

Request for a quote

KASAG SWISS AG

Switzerland

Our specialists have vast knowledge and many years of experience in non-destructive testing (NDT) of welding seams, welding constructions, pressure vessels, containers, equipment and plants. We use and offer the following testing procedures for that purpose: X-rays RT Dye penetrant testing PT Visual inspection VT Material testing/ Positive Material Identification PMI Helium leakage testing LT Riboflavin test Pressure tests of up to max. 1000 bar Surface roughness testing Ra/Rz Ferrit measurement Fe Wall thickness measurement Video endoscopy Pressure-loss test (liquid) With KASAG, you remain on the safe side.

Request for a quote

KASAG SWISS AG

Switzerland

We bring your ideas to life KASAG has a high level of competence, with many years of experience in design and construction of plants, apparatuses, pressure vessels, pipes and welded structures. Our engineers can assist you with the following: Strength calculation according to the global regulations, such as PED (EN13445 / AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) FEM-calculations (Finite element analysis) and providing proof for overpressure and underpressure, load alteration, earthquake, joint flanges, nozzle loads Consultancy for interpreting and analyses of computation results, material choice, regulatory authorities Constructive, design based on Autocad 2D and Inventor 3D Comprehensive plants engineering, such as compilation of technical specifications, P&I schemes, risk analyses, pipeline/piping planning

Request for a quote

KASAG SWISS AG

Switzerland

Are you using pressure vessels, apparatuses, pressure containers that are subject to the inspection cycles of the regulatory authorities? Would you like to have our advance expertise on the technical updates? Do you have problems with the cleaning of apparatuses, containers? Are you unsure about the technical details of the bought-in containers, apparatuses, and would you like them checked? We are experts in apparatus and pressure vessel construction and have comprehensive knowhow of the pressure equipment directive. For control, testing KASAG offers a wide range of non-destructive testing methods. Please get in touch with us, and our KASAG experts will be glad to offer you expertise.

Request for a quote

KASAG SWISS AG

Switzerland

The KASAG double-tipping station with integrated weighing cells guarantees simple handling of containers. So that minimal quantities of the remaining product sticks in the container.

Request for a quote

KASAG SWISS AG

Switzerland

The KASAG glove box is used for handling and controlling in sterile processing. The glove box with introducer sheath is equipped with a vibrating sieve and is used when powdery products are filled into bags. The KASAG bag sterilising gassing chamber is used to ensure sterile sealing of products in bags. For that, air is extracted (vacuum) and subsequently swapped with nitrogen. The equipment complies with the strictest hygienic regulations. The mounting can be easily adjusted to the size of the bag.

Request for a quote

KASAG SWISS AG

Switzerland

KASAG is a highly qualified partner for undertaking contract manufacturing on your behalf. Our machines and equipment for premium processing of stainless steels and aluminium alloys always allow us to meet any demand you might have. Machine for object size Container diameter up to Ø 4 m Object weight up to 13 t Object length up to16 m Material zone with Cr ? 19%, Ni ? 8% (1.4307, 1.4571, ...) with Cr ? 19%, Ni ? 12% (1.4539, 1.4828, …) Duplex (1.4462, 1.4410, …) Alloys NiCrFeMo mit Ni > 40% (Inconel, Hastelloy) Alloys Al – Mn und Mg (AlMg 4.5 Mn)

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quoteResults for

Special mechanical engineering - Import exportNumber of results

49 ProductsCategory

- Mechanical engineering - custom work (28)

- Automation - systems and equipment (2)

- 3D printers (1)

- Aeronautical equipment manufacturers (1)

- Bearings, roller (1)

- Cars - electrical and electronic parts and components (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Crate packing machinery (1)

- Electrical components and parts (1)

- Goods handling systems, continuous (1)

- Optical measuring equipment (1)

- Plastics - machines and material for industry (1)

- Steel (1)

- Vehicles - mechanical components and parts (1)