- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steam polishers

Results for

Steam polishers - Import export

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

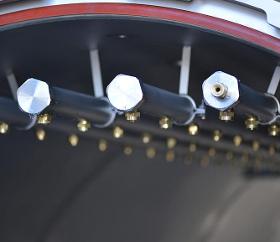

Through integration of the segmented disc valve technology, the desuperheater type 5090 is able to control steam pressure and temperature in the steam network easily. By using four injection nozzles and finely tuned water conditioning, process steam is generated from superheated steam at 3 20 K above the saturated steam temperature.

Request for a quote

GAICTECH

Spain

The Tuna Fish Steam Cooker is expertly designed to refine the production process for tuna, focusing on increasing total fish yield through precise thermal gradient control and moisture content preservation. This ensures the fish remains moist, facilitating easier cleaning post-cooking. Tailored for flexibility, it offers adaptations for client-specific trolleys and the option for cooking without vacuum, enhancing its utility in diverse processing environments. Remote support capabilities allow for diagnostics and adjustments via PC and Ethernet, ensuring seamless operation and troubleshooting. Constructed from high-quality stainless steel AISI 304 L, the cooker is built for durability and hygiene compliance. Key features include a fully automatic cooking cycle, options for time or temperature-driven cooking directly in the fish's bone, and advanced process control via the latest generation PLC with exclusive tuna cooking programming. Temperature monitoring through thermocouple

Request for a quote

GAICTECH

Spain

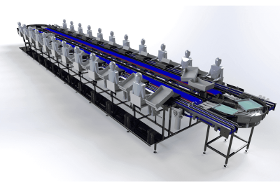

The Tunidae Classification Line is a sophisticated system designed for the automatic calibration of tunas, leveraging both size and weight metrics to ensure the highest yield during the cooking process and facilitate selective storage. This line is capable of handling up to 50000 kg/hour for fish up to 15 kgs/unit with a single line, and offers the option for expanded production through multiple parallel lines for outline-based classification. Weight-based classification capacities are tailored according to the range of sizes to be classified, ensuring versatility and adaptability to specific production requirements. Constructed from durable and hygienic stainless steel AISI 316-304, the system incorporates advanced features such as the combination of outline and weight classification for large-scale productions with high accuracy. It also allows for the preliminary manual classification of species, or through machine vision cameras, to remove non-predominant species

Request for a quote

GAICTECH

Spain

Designed for the continuous pasteurisation of a wide variety of products of animal or vegetable origin, packaged in any type of format. Production: According to the client’s needs. AISI 304 stainless steel construction. Features: Especially indicated in production lines where it is not possible to carry out discontinuous pasteursation in traditional autoclaves or when there are no space limitations. Automatic process control. Optimal steam consumption. Direct steam pasteurization.

Request for a quote

GAICTECH

Spain

The Pendular Autoclave is specifically designed to meet the sterilization needs of products with viscous sauces, utilizing a unique pendular movement that stirs the product, ensuring liquids and solid particles are evenly distributed throughout the container. This method not only prevents container damage but also significantly improves sterilization times, making it an ideal solution for preserving the quality and safety of food products. Constructed from AISI 304/316 stainless steel, the autoclave offers a range of diameters and lengths to accommodate various client requirements. It features the possibility of adding internal traction for the carts, streamlining the sterilization process and easing the workload for operators. Additionally, heat exchangers are made from high-quality Inox or Titanium, ensuring efficient temperature control and durability. Tailored to enhance the sterilization of products requiring gentle agitation, this autoclave represents a significant advancement

Request for a quote

GAICTECH

Spain

The Rotative Autoclave is specially designed for sterilizing products that require movement to ensure even heat distribution and quality. Its rotating carts stir the contents, allowing both liquids and solid particles to move across the container, which leads to faster heat transfer and uniformity within. This process not only improves the quality of the product but also ensures thorough sterilization. The autoclave is constructed from AISI 304/316, offering various diameters and lengths to meet client-specific needs. It includes options for internal traction to ease the workload of operators and features heat exchangers made of Inox or Titanium for durability and efficiency.

Request for a quote

GAICTECH

Spain

Designed for items that require a stationary sterilization process, this autoclave presents a solution for ensuring the safe and effective sterilization of various products without the need for rotation. Offering features that cater to operational efficiency and customization, it includes construction in AISI 304/316, options for different diameters and lengths tailored to client needs, the possibility of adding internal traction for the cars to ease operator workload, and heat exchangers made of Inox or Titanium.

Request for a quote

GAICTECH

Spain

The Automatic Autoclave Cart Circuit is an advanced system designed to enhance the efficiency of autoclave operations by autonomously managing the loading and unloading of baskets and autoclave carts. This comprehensive system integrates conveyor mechanisms for both the loading/unloading of autoclave carts and the accumulation of empty and/or full carts, ensuring seamless movement within the processing environment. At the heart of the system is complete and centralized automation of all equipment components, powered by comprehensive management software that optimizes workflow and reduces manual intervention. The system's versatility is highlighted by its compatibility with various cart sizes and autoclave diameters, accommodating autoclaves with either single or double doors. This adaptability makes it suitable for a wide range of processing needs, significantly improving operational throughput and safety. Constructed to meet the demanding

Request for a quote

GAICTECH

Spain

The Basket Loading system for Autoclave Carts is meticulously designed to optimize the filling and emptying of autoclave baskets with filled tins, significantly improving sterilization times and ensuring the careful handling of cans. Tailored to meet the specific needs of clients, this system is compatible with any type of packaging, including round, rectangular, oval, and glass, making it versatile for various production levels and requirements. Constructed from durable stainless steel AISI 304, it ensures longevity and compliance with hygiene standards. Offering several grades of automation, from semi-automatic to fully automatic, the system provides flexibility to integrate into existing operations seamlessly. It includes options for fitting in automatic lines for the efficient loading and unloading of autoclaves, enhancing the overall productivity of the sterilization process. Additionally, the system is equipped with troubleshooting capabilities via an ethernet connection

Request for a quote

GAICTECH

Spain

The Basket Unloading system for Autoclave Carts is engineered to enhance the efficiency of sterilization processes by facilitating the easy filling and emptying of autoclave baskets with filled tins, thereby improving sterilization time and ensuring the meticulous care of cans. Customizable to match the specific production requirements of each client, this system is adept at handling any type of packaging, be it round, rectangular, oval, or glass, and is scalable to suit any production level. Constructed from high-quality stainless steel AISI 304, it stands out for its durability and hygiene. The system offers varying degrees of automation, from semi-automatic operations to fully automatic systems with manual dividers, providing flexibility to seamlessly integrate into existing autoclave loading and unloading lines.

Request for a quote

GAICTECH

Spain

The Depalletizer for Empty Containers is specifically engineered to streamline the palletizing and depalletizing processes for both full and empty packages, catering to the versatile needs of production facilities. Designed to accommodate any type of packaging, including round, rectangular, oval, and glass containers, this system is adaptable to any production level, ensuring a seamless fit for operations large and small. Featuring several grades of automation, the depalletizer can handle the entry and exit of full or empty pallets, the construction and evacuation of layers in the palletizer/depalletizer, the placement of dividers, and the uplifting and downlifting of pallets. This flexibility allows for the optimization of processes and a significant reduction in costs by feeding multiple production lines with just one depalletizer.

Request for a quote

GAICTECH

Spain

Designed to cater to the specific needs of production facilities, the Palletizer for Pallets with Finished Products offers a versatile and efficient solution for the palletizing and depalletizing of both full and empty packages. Capable of handling any type of packaging, including round, rectangular, oval, and glass, this system is adaptable to various production levels, ensuring a seamless fit for any operation scale. It features multiple levels of automation that manage the entry and exit of pallets, the construction and evacuation of layers in the palletizer/depalletizer, the placement of dividers, and the uplifting and downlifting of pallets. This flexibility allows for the optimization of production processes and a reduction in operational costs by enabling multiple production lines to be fed with just one palletizer. Additionally, the system includes troubleshooting capabilities

Request for a quote

GAICTECH

Spain

The Continuous Cooker for Pelagics is an innovative solution designed to meet the needs of the seafood processing industry, offering efficient and uniform cooking of sardines and other pelagic fish. Whether the fish are canned or placed directly on grills, this cooker is equipped with optional features such as a hot air drying system and the possibility of including a continuous grill washing system beneath the cooker, enhancing operational efficiency and product quality. This cooker represents a significant advancement in seafood processing, offering a blend of efficiency, safety, and quality.

Request for a quote

GAICTECH

Spain

Designed for the efficient processing of small pelagic fish, this Cutting and Double Gutting Machine, made from high-quality stainless steel AISI 316-304, ensures durability and hygiene in seafood processing. Capable of handling up to 350 fish per minute, it offers flexibility with options to cut just the head or both head and tail, tailored to the size requirements of the output. The machine employs circular blades for precise cutting, coupled with a vacuum suction system for clean gut removal, storing waste in a built-in deposit or separately for ease of disposal. Its design includes adjustable transport buckets and an oversight system to immobilize fish during processing, ensuring consistent quality. This versatile machine is suitable for a variety of small pelagic fish, streamlining the cutting and gutting process with easy adjustments for different fish sizes, enhancing operational efficiency and product quality.

Request for a quote

GAICTECH

Spain

The Cutting and Gutting / Nobbing Machine is specifically designed for the automated de-heading and gutting of pelagic fish species such as sardines, horse mackerel, and mackerel, crafted from durable stainless steel AISI 316-304 for longevity and food safety. Capable of processing up to 350 fish per minute in a standard setup, and optionally up to 500 fish per minute depending on the fish type, this machine offers versatility with options to cut just the head or both head and tail. It features transport buckets designed to accommodate varying fish sizes and desired product outcomes, using sharp circular blades for precise cutting and a vacuum suction for efficient gut removal, with options for internal or separate waste storage. The machine includes an easy-to-adjust cutting regulation system to cater to different fish sizes and an upper oversight system that immobilizes fish during processing, ensuring consistency and quality.

Request for a quote

GAICTECH

Spain

Designed for the high-efficiency de-scaling of sardines and other pelagic fish, this machine is tailored to meet specific client production requirements, ensuring a seamless integration into existing processing lines. Constructed from durable and hygienic stainless steel AISI 316-304, it features a rotary drum equipped with a special mesh optimized for the de-scaling process, coupled with an internal helicoid that facilitates the smooth movement of fish through the machine. Water jets assist in the removal of scales, enhancing the efficiency of the process, while a collection tray efficiently gathers water and scales, minimizing waste and facilitating cleanup. Optional features include a scales filtering system for enhanced separation and a gateway for easy maintenance and control, offering increased operational flexibility and maintenance convenience. This de-scaling machine represents a significant advancement in seafood processing technology, providing

Request for a quote

GAICTECH

Spain

Tailored to the specific needs of the seafood processing industry, this Pelagic Classification Line is engineered to automatically calibrate various pelagic species such as sardine, mackerel, and horse mackerel by size or weight. This ensures the highest yield during cooking processes and facilitates selective storage. Constructed from high-quality stainless steel AISI 316-304 for durability and hygiene, the line can accommodate up to 3 + 1 (oversize) classifications, with options available for additional classifications upon request. It features grading by divergent bars and mobile trays for the collection of calibrated sizes, with the option to install conveyors for each calibre. The machine's tilting can be adjusted based on the specific fish being graded, and the opening of the divergent bars is variable to accommodate different sizes. Pre-installation for fresh water supply is included to ease the movement of fish through the system

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GAICTECH

Spain

The Sardine Gutting Machine is meticulously designed for the specific task of gutting sardines, ensuring high efficiency and precision in seafood processing. Capable of handling up to 300 fish per minute, this machine features a transport system with specially designed belts to smoothly drag the fish through the gutting process. It performs both the trunk cut by the front and the belly cut by the side, utilizing two circular blades for the gutting system. Constructed from durable stainless steel AISI 316-304, the machine combines robustness with ease of maintenance. Its simple operation is complemented by a flip-top lid offering easy access to internal mechanisms, equipped with an electrical interlock for enhanced safety during maintenance or accidental openings. This gutting machine can seamlessly connect with any cutting-gutting machine on the market, offering versatility

Request for a quote

GAICTECH

Spain

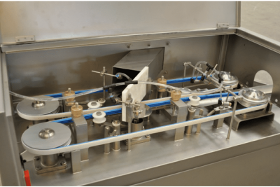

The Sardine Packing Line is expertly crafted to enhance the manual packaging process for pelagic species such as sardines, anchovies, mackerel, and horse mackerel, ensuring efficiency and optimal presentation. Constructed from high-quality stainless steel AISI 316-304, it offers durability and meets stringent hygiene standards. Tailored to the specific production requirements and packaging formats demanded by the market, this line is designed with ergonomics in mind, facilitating ease of use and minimizing operator fatigue. It features a special design for rectangular formats like ¼ Club, Dingley, or similar, allowing operators to achieve higher yields through dynamic packaging methods that result in an excellent presentation of the fish. The line also includes options for directing containers to grills or cookers and is equipped for integration with an automatic feeder of empty containers, further streamlining the packaging process.

Request for a quote

GAICTECH

Spain

The Bagging Machine for Tuna Loins is designed for the semi-automatic insertion of cooked and clean tuna loins into bags, streamlining the preparation process for subsequent freezing. Capable of handling 7 kg bags at a rate of up to 8 bags per minute and 10 kg bags at up to 6 bags per minute, this machine requires 4-5 operators for optimal performance. Constructed from durable and hygienic stainless steel AISI 316-304, it ensures longevity and compliance with food safety standards. The volumetric filling system guarantees great uniformity in the volume of bags filled, without producing pieces or flakes, enhancing product quality. Its design facilitates easy cleaning, as it can be fully disassembled, allowing all parts to be accessible. Additionally, the machine offers the flexibility to work with several bag sizes by simply modifying the length, accommodating various packaging needs. This bagging machine represents a significant efficiency

Request for a quote

GAICTECH

Spain

Designed for robust industrial cutting tasks, this Chop Saw features a cutting power of 6 CV at 1,800 revolutions per minute, ensuring efficient and precise cuts across various materials. Its design is shielded for direct washing with high-pressure water, enhancing cleanliness and maintenance ease. The saw offers manual height adjustment of the protection guide and pulleys with a 400 mm diameter made from stainless steel, ensuring durability. With a saw blade width of 20 mm and manual tensioning, as well as an adjustable steering wheels tilt, it provides versatility for different cutting needs. The maximum cutting dimensions include a height of 600 mm and a width of 800 mm, catering to large materials. The working table measures approximately 1,000x900 mm, offering ample space for various projects. It accommodates both right-hand and left-hand cutting, with a special guide

Request for a quote

GAICTECH

Spain

These Cleaning Lines are meticulously designed to enable operators to achieve high productivity levels and optimum performance in tuna processing. Tailored to meet the specific needs of each client, these lines offer optional features such as different designs based on available space, the choice between a closed circuit for unclean fish and clean loins (recommended) or a straight-line design, and the possibility of individual tables for each operator. Dimensions are adapted to client production requirements, and the construction is made of durable and hygienic stainless steel AISI 316-304. The lines facilitate the entry and exit of boxes with clean or unclean fish, either automatically or manually, and feature transport of unclean fish, clean loins, and waste in independent, differentiated areas. Production control options include the ability to monitor each operator in real time, with total and per operator yields and traceability. Custom programs can be tailored to client

Request for a quote

GAICTECH

Spain

This Loin-Mincing Machine is engineered to precisely cut or mince tuna loins to predetermined lengths, facilitating efficient preparation for bagging or other packaging formats. Crafted from durable and hygienic stainless steel AISI 316-304, it ensures longevity and adherence to food safety standards. The machine features a conveyor system equipped with a canvas belt designed for food purposes, moving tuna loins smoothly to the cutting area. A blade with vertical movement performs the cutting, offering the option to adjust the length of the cut to meet specific requirements. Digital indicators provide precise control over the cut length, ensuring uniformity across all products. Safety is a priority, with doors equipped with electrical interlocks to protect operators in case of accidental opening during the cutting process. This loin-mincing machine represents

Request for a quote

GAICTECH

Spain

The Pin-Bone Remover Machine is an innovative solution designed to efficiently remove bones from various types of fish and the shell from crustaceans such as shrimps, prawns, or king prawns, whether raw or cooked. This versatility ensures the production of an excellent product for a wide range of applications. The machine offers optional features like constant and controlled feeding through a helicoid mounted on the reception hopper and customizable diameters of the holes in the drum (between 1.5 and 8 mm), depending on the desired product outcome. Constructed from durable stainless steel AISI 304, it meets the highest standards of hygiene and longevity. In the canning industry, particularly for tuna, it's used to separate bones from flakes generated during the cleaning process, with a perforated drum that's easy to assemble or disassemble. The diameter of the holes can be adjusted to balance production and flake quality, with smaller diameters

Request for a quote

GAICTECH

Spain

Tailored to meet the specific production needs of clients, the Tuna Cooking Blancher is an advanced machine designed for the optimal cooking of tuna. It features a lid closure system operated by a hydraulic cylinder, ensuring a watertight seal with a water gutter that prevents steam from escaping, except through a designated duct at the rear. This design not only prevents steam buildup in the workspace but also reduces cooking time by efficiently managing steam release. Fat collection is ingeniously handled at the back of the blancher, with front-located water diffusers activated during fish removal to drag the fat layer away, ensuring it doesn't impregnate the fish. Temperature control is achieved via a strategically placed thermocouple, with steam flow managed by electrovalves. Additionally, cooking time is meticulously controlled by a programmer, alerting operators with both visual and auditory signals when the process is complete. The interface includes a touch screen

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC machine tool with 6 axis for belt grinding, polishing and belt linishing aircraft engine airfoils such as fan blades, vanes (OGVs and IGVs), steam turbine blades and gas turbine compressor blades and vanes. Extreme high precision and repeatable stock removal allows balancing of milling process to save milling time and cutter costs by maximizing milling roughness followed by MTS process.

Request for a quoteResults for

Steam polishers - Import exportNumber of results

27 ProductsCountries

Company type