- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pharmaceutical

Results for

Pharmaceutical - Import export

EOSWISS PHARMA

Switzerland

Based on your requirements, we search for and find suitable contract manufacturers. We prepare your tender documents and make a pre-selection of suitable contract manufacturers (CMOs, CDMOs). Contact us for an initial discussion! We evaluate the CMOs for this in a structured scheme. We use not only the bid price, but also the important parts of the bid: •Flexibility •Smallest order quantity ("MOQ") •Terms of payment •Logistics opportunities •Development support •Potential for the future This allows you to choose the best contract manufacturer for your project! You then transfer your technology or product, or hand over this work package to us. We transfer even complex productions and technologies within 6 -12 months. This means you are on the market very quickly, your resources are not blocked. Contact us for an initial discussion!

Request for a quote

EOSWISS PHARMA

Switzerland

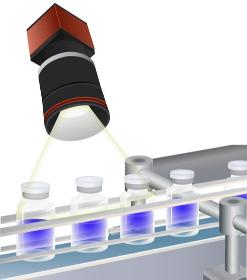

We support your manufacturing with our polarised light camera and analytical software. We film production issues of transparent material (vials, blisters, glass items, foils) with polarized light. Defects, scratches, flaws, residual tensions brought in during manufacturing become visible. Hence, they can be corrected and improved. You receive an improved manufacturing process, with higher quality and higher capacity.

Request for a quote

EOSWISS PHARMA

Switzerland

We plan and perform your complete process validation. From the first gap analysis and risk management, planning, execution and reporting. We support you with full project management, providing support where needed. You free your ressources for your projects, we take care for validations and all connected activities. You reach your goals safely, quicker and faster.

Request for a quote

EOSWISS PHARMA

Switzerland

We carry out the entire technology transfer or production transfer from a manufacturer to a contract manufacturer (CMO, CDMO) for you. Contact us for an initial discussion! In the process, we look for the right CMO for you and prepare a pre-selection. You decide on the best manufacturer, then we carry out the entire transfer for you: •Planning resources •Timetable including work packages •Structure the cooperation with the CMO •Prepare all necessary documents •technical transfer •Adjusting the production parameters, optimisation •we validate the transferred production process •handed over to routine production We bring all the necessary specialists into the project ourselves, or work hand in hand with your internal team. Depending on how it is needed. We carry out transfers very quickly. This shortens the project duration and reduces your costs: They are quickly back on the market! This reduces transfer costs in the long term. Contact us for an initial discussion!

Request for a quote

EOSWISS PHARMA

Switzerland

The strong supply chain is the basic prerequisite for a strong brand, even for completely virtual pharmaceutical companies such as biotech start-ups. We search and find new contract manufacturers (CMO, CDMO) for you. Contact us for an initial discussion! You benefit from our proven evaluation system that we have developed for various industries. Because with the CMO, it's not just the price of 1 packaged unit that matters, but also the price of the product: •Flexibility of delivery dates and minimum order quantity •Terms of payment •Logistics solutions •Packaging option •Audit status •Development support •Potential of the contract manufacturer Depending on your individual requirements profile, we find suitable contract manufacturers with our carefully prepared tender documents. In this way, you reduce your overall costs and further develop your suppliers. Contact us for an initial discussion! Supplier management We take over the continuous control and improvement

Request for a quote

EOSWISS PHARMA

Switzerland

Statistical experimental design We plan your trials in development and production. With our statistical methods, you can optimise production during normal operation. This saves you technical batches and thus costs. Nevertheless, you gain resilient and robust improvements. Statistical design of experiments is the fastest and most cost-effective way to carry out developments and optimisations. Contact us for an initial discussion! CPV "Continouus Process Verification With CPV, the manufacturing process is checked for variable proportions, trends and opportunities for improvement. As such, it is part of the "Life Cycle Management" to further operate the process in a controlled manner within narrow limits. We evaluate your process data statistically and thus show potential for improvement. This way you use your data productively and can achieve strong savings and improvements in quality. So it pays off! Contact us for an initial discussion! Quality by Design "QbD

Request for a quote

EOSWISS PHARMA

Switzerland

We carry out projects quickly and without loss of quality. You have short project durations, thus lower costs and a quick return on investment. Contact us for an initial discussion! Our projects often combine Technical and regulatory issues: •Technology & technology transfer (adapt, improve technologies) •Optimise in production •Quality projects (Quality by Design "QbD", Process Analytical Technology "PAT", test design, validations, qualifications) •Short processing times in administration •Improve the supply chain We optimise supply chains, develop suppliers, um/damit: •"Shorten "Lead Times •the supplier reacts quickly •broaden the supplier base •find new suppliers •Relocate productions We take over technical projects like: •"Scale up" in biotechnology and pharmaceuticals •Model and simulate production steps in biotechnology and pharmaceuticals •Improve production processes (quality, process) •modelling new or modified buildings ("virtual factory") •simulate

Request for a quote

EOSWISS PHARMA

Switzerland

We manage investment projects for you, such as production expansions, installation of new plants, greenfield construction projects, brownfield construction projects. We focus on the rapid implementation of your project. With these short project durations, you have low project costs and a high return on investment. We adapt our project management to the very specific circumstances of our clients Contact us for an initial discussion! This makes our project management flexible enough to handle the changes that occur in every project. Our focus is on short "time to market" and thus low project costs. This is the only way for projects to pay off quickly. We execute projects very quickly and achieve significant time savings compared to traditional project management. Pharmaceutical production •After qualification and commissioning, we also take care of the start of production. •Optimisation of the production parameters •Validation •Transfer to routine operation

Request for a quote

EOSWISS PHARMA

Switzerland

The step from the laboratory to manufacturing for clinical trials is a major challenge. Simple hand movements in the laboratory often cannot be easily translated into process steps of industrial manufacturing. We are specialised in such scale ups. Contact us for an initial discussion! Analysis We prepare your laboratory data and compare it with the possible process parameters at the contract manufacturer. If data or optimisations are still missing. We develop the test plan for this. We carry out certain scale-up trials (non GMP) at our technical centre. We accompany specific trials (e.g. with your API) on your premises or those of a plant manufacturer. Models and simulation From the data, we generate the process models you need for scaling up. You will also need these models for the submission documents. We use the data to simulate different scale-up concepts. So if you later transfer from the special CDMO for clinical production to the CDMO for commercial production

Request for a quote

HO-MATIC AG

Switzerland

Our stainless steel pinch valve for unlimited applications in the pharmaceutical, chemical and food industries and everywhere where the highest demands are placed on material and durability. screw connection G 3/8” – G 2” DN10 – DN50

Request for a quote

KASAG SWISS AG

Switzerland

The task of storing liquids hazardous to water or to their processing must be handled responsibly. In the building of the corresponding process containers, storage tanks, stainless steel containers, different factors must be taken into consideration. They are designed according to regulations, such as PED (AD-2000, SVTI, EN13445) or according to special standards, such as the Basel chemical standard BN76 and manufactured in stainless steel. Process containers and storage tanks have half-pipe coils, jackets or laser-welded structures (pillow plates) for heating and cooling purposes. KASAG is the competent place if you are looking for replacement, modification, extension or reconstruction of complete tank plants. We will share your responsibilities.

Request for a quote

KASAG SWISS AG

Switzerland

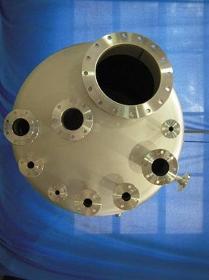

Pressure vessels, reactors, Pharmaceutical and biotech pressure vessles, Process containers, storage tanks, Modules, components, plants, High-pressure apparatuses,Heat exchangers, vaporisers, condensers, Cryo pressure vessels, technologies Nuclear technology, Vacuum chambers, vacuum apparatuses, Columns, according to PED (EN13445 / AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) Pharmaceutical and biotech apparatuses are calculated and manufactured according to your requirements. Stainless steel and special materials are used in the production. After that, the products are grinded, electropolished and tested using non-destructive testing methods, such as ferrite measurements, used for the determination of the ferrite content, or by using the riboflavin test to measure total discharge and CIP/SIP capability. All materials, methods and processes used have been documented in full in detailed QA documents and can be tracked at any time. You can depend on KASAG.

Request for a quote

INVITRO-CONNECT GMBH

Switzerland

https://www.invitro-connect.com/en - Your International Experts for Laboratory Testing and Regulatory Services - More than 80 test laboratories in our network - Product safety - Regulatory service - in vitro tests - All OECD tests for pharmaceuticals, chemicals, medical devices and cosmetics - in-house toxicologistes - Preclinical Services - Project management - Study monitoring --> complete services - all from one hand !!! --> contact@invitro-connect.com We would like to manage also your projects. Best regards Dr. Ute Hassmann (Deputy Managing Director) and Pascal Piller (Managing Director) INVITRO-CONNECT GmbH #biocides #toxicological #chemicals #laboratory #regulatory #affairs #reach #projectmanagement #pharma #medical #study #devices #Labor #GLP #cosmetics

Request for a quote

BÜCHI AG

Switzerland

Probes for process control Probes are available to measure the different process parameters. These values can be displayed on our monitoring instrument and recorded in our bls software, see measure & control. Frequently measured parameters are: temperature pressure stirrer speed torque pH IR probes, probes to control particle sizes etc. from other suppliers can be integrated into our pressure reactors or stirred autoclaves.

Request for a quote

BÜCHI AG

Switzerland

Feeding of liquids, solid, gas Burettes Volume: 10 - 1000 ml Pressure: depending on material Material: Glass, stainless steel, Hastelloy® Burettes are available in glass with protective jacket or as full metal version for higher pressures with sightglass. Feeding funnels enable fast charge of solids and liquids.

Request for a quote

BÜCHI AG

Switzerland

Sampling systems for manual and automated sampling Systems for manual and automated sampling (up to 4 samples per run) during pressure reactions, see also Parallel Pressure Reactor system PPR. Sampling system for pressure reactors, Sampling with the reactor under pressure, with immersion tube and filter, sampling cylinder, Connection for flushing the lines and sampling cylinder

Request for a quote

BÜCHI AG

Switzerland

Catalyst testing, catalyst screening Catalyst testing covers several types of research such as catalyst effectiveness, yield, activation, lifetime and regeneration. The type of catalyst baskets varies depending on the catalyst being used, the interaction with the chemistry, the temperature, the pressure and the number of catalysts in the basket. Exposure to the reactants can be done through a stationary catalyst bed or a spinning basket. Our special accessories offer solutions for more complex problems in pressure reactions in the field of catalyst research.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BÜCHI AG

Switzerland

Depending on the stirring or mixing task, Buchi reactors can be equipped with stirrers of different types. For gas entrainment as in hydrogenations, the Rushton type turbine stirrer is often used.

Request for a quote

BÜCHI AG

Switzerland

Corrosion testing requires the realistic simulation of the process environment. These environments often include HPHT (high pressure high temperature) conditions. Thanks to our proprietary designs and the use of high-performance materials our industry leading HPHT corrosion testing autoclaves are suitable for the most challenging corrosion testing applications. We have worked jointly with customers from various industries such as upstream and downstream oil & gas, petrochemicals, steel, nuclear and conventional power generation, inspection, certification and testing to design, engineer and manufacture customized corrosion testing solutions for their individual applications.

Request for a quote

BÜCHI AG

Switzerland

Metal-free magnetic coupling bmd 250 i / cyclone 250 i ac Torque: 250 Ncm Temperature range: - 20 °C to +250 °C Pressure range: full vacuum - 60 bar / 1000 psi Stirrer speed: 0 - 2500 rpm Materials: ceramic Metal-free magnetic couplings (bmd 250 i) and stirrer drives (cyclone 250 i ac) feature inert behavior and full corrosion resistance, as no metal can get in contact with the process media. Built in our reactor systems versoclave, polyclave, kiloclave and in combination with pressure vessels in glass or glass-lined steel, we offer complete metal-free solutions.

Request for a quote

BÜCHI AG

Switzerland

cyclone 075 dc / 300 ac - stirrer drives with magnetic coupling Torque range: 75, 300 Ncm Temperature range: - 50 °C to + 400 °C Pressure range: full vacuum - 500 bar / 6000 psi Stirrer speed: 0 - 2000 / 3000 rpm Materials: stainless steel, Hastelloy®, Tantalum, Titanium, ceramic etc. Buchiglas magnetic stirrer drives (cyclone) are produced for the mixing of chemicals of low to high viscosity in pressurized lab reactors. Cyclone type magnetic stirrer drives have integrated motors and controllers for the stirrer rotation speed.

Request for a quote

BÜCHI AG

Switzerland

bmd 075 - 5400 magnetic couplings Torque range: 50 - 5400 Ncm Temperature range: -50 °C to +500 °C Pressure range: full vacuum - 500 bar / 6000 psi Materials: stainless steel, Hastelloy®, Tantalum, Titanium, ceramic etc. Buchi magnetic couplings (bmd) are produced for mixing of chemicals of low to very high viscosities and under full vacuum to high pressure. Magnetic couplings are combined with stirrer motor and speed transmission for manual speed adjustment or with frequency converter. Buchi bmd magnetic couplings are available for ATEX rated area.

Request for a quote

BÜCHI AG

Switzerland

Pressure reactor for kilo labs and small-scale production Reactor volume: 20 to 500 liter Pressure: -1 (FV) to +200 bar Temperature: -20 °C to +300 °C Material: stainless steel, Hastelloy® Other materials, pressures & temperatures are available Buchi pilot plants are built for pressure reactions as well as for reactions under full vacuum. Different technologies and materials are used, depending on the requested process and process media. Pilotclave pressure reactors range from 50 - 500 liter and are all customized. To quote such systems we require detailed specifications. Safety is important with such larger scale systems, especially when doing hydrogenations and other reactions under higher pressure. The degree of automation and process control vary from simple data collection to complete automation of the system. In most cases, the reaction vessels are jacketed steel or Hastelloy® reactors.

Request for a quote

BÜCHI AG

Switzerland

For dependable and reproducible hydrogenations Buchi gas dosing system bpc 2 in combination with Buchi pressure reactors creates an optimal solution for safe, accurate and reproducible hydrogenations. The Buchi hydrogenator is a turnkey hydrogenation solution, consisting of: bpc 2 (Buchi pressflow controller) for hydrogen dosing, control of reaction pressure and continuous measuring of the Hydrogen uptake until saturation Buchi pressure reactors, offered in different materials and volumes for high to low pressure applications The unique volumetric hydrogen gas dosing records the parameters pressure, momentary consumption and overall consumption. The optional bls3 allows Operation of the apparatus via PC and storing or recorded data for further analyses.

Request for a quote

BÜCHI AG

Switzerland

Laboratory pressure reactor system - metal-free executions Reactor volume: 1.0 - 20.0 liter Pressure: -1 (FV) to + 6 bar Temperature: -20 °C to +180 °C Material: glass, glass-lined steel, ceramic, PFA, PEEK, PTFE Our lab to pilot scale reactor models are available as metal-free / inert versions: polyclave inert versoclave inert (available only with glass-lined steel vessel) kiloclave inert (available only with glass-lined steel vessel) These multipurpose pressure reactor systems ensure high resistance against aggressive chemicals, while avoiding corrosion and contamination or side reactions with metals. They are designed for the use with either glass-lined steel pressure vessels or with glass pressure vessels. The use of high torque ceramic magnetic stirrer drive ensures efficient mixing of low to high viscosity process media as well as excellent heat transfer.

Request for a quote

BÜCHI AG

Switzerland

Inert laboratory pressure reactor system Reactor volume: 100 - 300 ml Pressure: -1 (FV) to +10 bar Temperature: -20 °C to +150 °C Material: Borosilicate glass 3.3, PTFE, PFA, FEP Special executions are available. This metal - free pressure reactor system is designed for the use of interchangeable glass pressure vessels. All product touched parts are made of inert (non-metallic) materials. Safety features guarantee safe reactions under pressure. The glass reactors ensure high resistance against acids, while allowing visual process control and monitoring. A wide range of accessories is available – talk to us to define the right setup for your specific need.

Request for a quote

BÜCHI AG

Switzerland

Laboratory high pressure reactor system Reactor volume: 0.5 - 5.0 liter Pressure: -1 (FV) to +350 bar Temperature: -20 °C to +350 °C Material: stainless-steel, Hastelloy® Other materials, pressures & temperatures are available. This high pressure reactor system is designed for the use of interchangeable steel pressure vessels. Safety features guarantee safe reactions under pressure. The stainless steel or Hastelloy® reactors ensure high resistance against acids. The high torque magnetic drive ensures efficient mixing and stirring of the process media as well as excellent heat transfer. The system is equipped with a lifting device for vessel and electric heating. The modular setup of the limbo ls system allows changing or upgrading for new tasks at any time.

Request for a quote

BÜCHI AG

Switzerland

Laboratory high pressure / high temperature reactor (HPHT) Standard Version: Reactor volume: 100 - 600 ml Pressure: -1 (FV) to +400 bar Temperature: -20 °C to + 400 °C Material: stainless steel, (Hastelloy® +400 °C) High-Pressure Version: Reactor volume: 100 - 600 ml Pressure: -1 (FV) to +500 bar Temperature: -20 °C to + 500 °C Material: stainless steel, (Hastelloy® +400 °C) This is our new high pressure and high temperature HPHT (high pressure high temperature) autoclave novoclave. This high pressure reactor system is designed for processes involving high pressures and temperatures. Safety features guarantee safe reactions under highest pressure. Designed, manufactured, and tested according to PED, AD2000. The modular setup of the novoclave system allows for changing the vessel size from 100 ml up to 600 ml using the same cover plate and electric heating block. Vessels are available in the following volumes: 100, 200, 300, 450, 600 ml.

Request for a quote

BÜCHI AG

Switzerland

Laboratory high pressure reactor system Reactor volume: 0.1 - 1.0 liter Pressure: -1 (FV) to +200 bar Temperature: -20 °C to +300 °C Material: stainless steel, Hastelloy® Other materials, pressures & temperatures are available This high pressure reactor system is designed for the use of interchangeable steel pressure vessels. Safety features guarantee safe reactions under pressure. The stainless steel or Hastelloy reactors ensure high resistance against acids. Visual process control and monitoring is also possible under high pressure by using steel pressure vessels with sight glasses. Various low to high torque magnetic drives ensure efficient mixing and stirring low to high viscosity process media as well as excellent heat transfer. The fast action closure and vessel lift makes changing vessels quick and easy without the use of tools. The modular setup of the midiclave system allows changing or upgrading for new tasks at any time.

Request for a quoteResults for

Pharmaceutical - Import exportNumber of results

52 ProductsCountries

Company type