- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- transmission shafts

Results for

Transmission shafts - Import export

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

ROLLON GMBH

Germany

“Lift and move” motion profile with multiple stations and long travel lengths. Synchronized movement system with hard anodized profiles. Polyamide nylon wheels with a rack and pinion system manage horizontal and vertical movement. Column modules carry out lifting movement via a recirculating ball screw drive. The column modules are operated with a single geared motor through a transmission with shafts and corner stops. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

The Pritzwalk gear factory produces gears and toothed shafts. Experience since 1969 with location in Brandenburg. We manufacture planetary gears, sun shafts and other geared items on request. Our well-known customers come from the following sectors: railway, wind power, crane manufacture, industrial gears, mining and special machine construction as well as power generation. As one of the largest independent contract manufacturers in Germany, ZWP manufactures extensive gearing articles. Our customers include renowned and well-known companies. References available on request. We manufacture according to customer drawings and have our own hardening shop. This saves time and money in production. There is also cooperation for other hardening processes such as gas nitriding or single-tooth induction hardening with experts in their field or with colleagues. We look forward hearing from you and are happy to support renewable energies.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

The Pritzwalk gear factory produces gears and toothed shafts. Experience since 1969 with location in Brandenburg / Germany. We manufacture planetary gears, sun shafts and other geared items on request. Our well-known customers come from the following sectors: railway, wind power, crane manufacture, industrial gears, mining and special machine construction as well as power generation. As one of the largest independent contract manufacturers in Germany, ZWP manufactures extensive gearing articles. Heat treatment inhouse. Our customers include renowned and well-known companies. References available on request. We manufacture according to customer drawings and have our own hardening shop. This saves time and money in production. There is also cooperation for other hardening processes such as gas nitriding or single-tooth induction hardening with experts in their field or with colleagues. We look forward hearing from you and are happy to support renewable energies.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

The Pritzwalk gear factory produces gears and toothed shafts. Experience since 1969 with location in Brandenburg. We manufacture planetary gears, sun shafts and other geared items on request. Our well-known customers come from the following sectors: railway, wind power, crane manufacture, industrial gears, mining and special machine construction as well as power generation. As one of the largest independent contract manufacturers in Germany, ZWP manufactures extensive gearing articles. Our customers include renowned and well-known companies. References available on request. We manufacture according to customer drawings and have our own hardening shop. This saves time and money in production. There is also cooperation for other hardening processes such as gas nitriding or single-tooth induction hardening with experts in their field or with colleagues. We look forward hearing from you and are happy to support renewable energies.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

The Pritzwalk gear factory produces gears and toothed shafts. Experience since 1969 with location in Brandenburg. We manufacture planetary gears, sun shafts and other geared items on request. Our well-known customers come from the following sectors: railway, wind power, crane manufacture, industrial gears, mining and special machine construction as well as power generation. As one of the largest independent contract manufacturers in Germany, ZWP manufactures extensive gearing articles. Our customers include renowned and well-known companies. References available on request. We manufacture according to customer drawings and have our own hardening shop. This saves time and money in production. There is also cooperation for other hardening processes such as gas nitriding or single-tooth induction hardening with experts in their field or with colleagues. We look forward hearing from you and are happy to support renewable energies.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

The Pritzwalk gear factory produces gears and toothed shafts. Experience since 1969 with location in Brandenburg. We manufacture planetary gears, sun shafts and other geared items on request. Our well-known customers come from the following sectors: railway, wind power, crane manufacture, industrial gears, mining and special machine construction as well as power generation. As one of the largest independent contract manufacturers in Germany, ZWP manufactures extensive gearing articles. Our customers include renowned and well-known companies. References available on request. We manufacture according to customer drawings and have our own hardening shop. This saves time and money in production. There is also cooperation for other hardening processes such as gas nitriding or single-tooth induction hardening with experts in their field or with colleagues. We look forward hearing from you and are happy to support renewable energies.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

The Pritzwalk gear factory produces gears and toothed shafts. Experience since 1969 with location in Brandenburg. We manufacture planetary gears, sun shafts and other geared items on request. Our well-known customers come from the following sectors: railway, wind power, crane manufacture, industrial gears, mining and special machine construction as well as power generation. As one of the largest independent contract manufacturers in Germany, ZWP manufactures extensive gearing articles. Our customers include renowned and well-known companies. References available on request. We manufacture according to customer drawings and have our own hardening shop. This saves time and money in production. There is also cooperation for other hardening processes such as gas nitriding or single-tooth induction hardening with experts in their field or with colleagues. We look forward hearing from you and are happy to support renewable energies.

Request for a quote

NOVELTY STEEL

Turkey

Transmission Shafts: These include counter shafts, line shafts, and overhead shafts. They are primarily used to transmit power between the source and the machine absorbing power. The transmission shafts are used to rotate the gears and provide mechanical power for various applications. Machine Shafts: These are an integral part of the machine itself. The best examples are the shafts used in motors and gearboxes. Spindle: A spindle is a type of shaft that is used to hold and drive work pieces in, for example, lathe machines. They are designed to withstand high torsional loads and are precision-made. Hollow Shafts: These shafts are similar to solid shafts but are hollow in the middle. They are used in applications where weight is a concern, as they are lighter than solid shafts of the same strength. Stepped Shafts: These shafts have different diameters in different sections. They are often used in machines where the shaft needs to perform different functions, requiri

Request for a quoteSTÄHLE GMBH

Germany

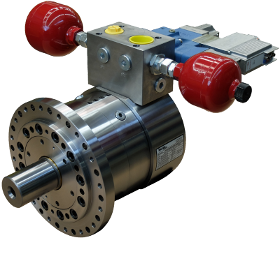

Single-axis shifter system for computer controlled shifting of gear boxes on test stands. This robot shifter system is a special design for end-of-line motor cycle gear box tests stands and allows automated docking to the original transmission shaft. It uses the real-time application software Autopilot32. Different options such as clutch actuators and different integration interfaces are available. The set-up is done by a quick and simple teach in which is proceeded with a special pendant / handy terminal.

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Thanks to a wide range of accessories, Hense operators can be individually configured for a wide variety of applications and optimally matched to the function of the overall system. To ensure perfect and safe operation, we are on hand to help you select and optimally coordinate all components.Servo valves, proportional valves and switching valves with different nominal sizes Pulsation damper for smoothing vibrations and uneven flow rates Subplates for positioning valves and pulsation accumulators close to the motor High-resolution rotation angle sensors that are coupled directly to the swivel motor shaft by means of a torsionally rigid coupling Pressure sensors Torque measuring shafts or reference torque measuring disks Clamping sets, shrink disks or profiled hubs for torque transmission Torsionally rigid couplings for reliable torque transmission with simultaneous shaft displacement Angled flanges for mounting the swivel motors parallel to the axis

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Custom Auto Shaft 1. All Custom Auto Shaft is produced according to your CAD and 3D drawings or sample. Please send the blueprint or drawing artwork first, and we will offer our quotation to you ASAP. 2. Materials: Copper, Brass, Phosphor bronze, Beryllium Copper, Aluminum, Stainless steel, Carbon steel, and Iron. 3. The surface finish of the Precision Stainless Steel Machining shaft includes: Electro-polishing, Electroless nickel plating, Silver plating, Golden plating, Zinc plating, TIN plating, Chrome plating, Bead Blasting, Phosphating, Turning, Heat treatment, Carburization, Case hardening, Sand blasting, Passivate, etc. 4. Testing facility: Coordinate measuring machine, projector, roughness tester, hardness tester, and concentricity tester. Height tester, 5. Part size: Diameter from 0.5mm to 150mm 6. Tolerance: +/-0.01mm, Or as your requirement 7. Lead time: 5-25 days after the confirmation of the sample.

Request for a quote

NOVOSIM

Turkey

test system for axles, transmissions, gears, transfer cases and shafts The development of rotating components requires intensive testing. While the primary goal may be to achieve strength and life performance, noise, vibration, temperature and other parameters can play an important role for customer expectations. Novosim therefore offers a customizable test dynamometer that can be used in the development of passenger car, commercial, truck or even military vehicle components. The software is easy to use and also highly customizable, allowing different product lines to be tested within a single system. With regenerative braking, power is recovered and returned to the test system, ensuring efficient operation. Considering that tests can last about 1 month, costs can be an important parameter to control costs. Different types of data can be collected and stored in a database for further comparisons and tracking of the development process.

Request for a quote

NOVOSIM

Turkey

The development of rotating components requires intensive testing. While the primary goal may be to achieve strength and life performance, noise, vibration, temperature and other parameters can play an important role for customer expectations. Novosim therefore offers a customizable test dynamometer that can be used in the development of passenger car, commercial, truck or even military vehicle components. The software is easy to use and also highly customizable, allowing different product lines to be tested within a single system. With regenerative braking, power is recovered and returned to the test system, ensuring efficient operation. Considering that tests can last about 1 month, costs can be an important parameter to control costs. Different types of data can be collected and stored in a database for further comparisons and tracking of the development process.

Request for a quote

NOVOSIM

Turkey

Development of rotating components require intensive testing. While the main goal may be reaching durability and life targets,noise , vibration, temperature and other parameters may play an important role for the customer expectations. Therefore, Novosim offers a customizable testing dynamometer which may be used to in the product development of passenger, commercial, heavy duty or even military vehicle components. Software is easy to use and also highly customizable allowing different product lines to be tested under a single system. With the help of regenerative braking, electricity is recovered and loops back to the test system providing efficient operation. Assuming the tests may run about 1 month, the consumption can be an important parameter for cost control. Different types of data can be collected and stored in a database for further comparisons and tracking of the development process. System automatically generates a report which is also customizable.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

In respect of rolling the serration type working pieces as the transmission shafts of autobobile/motor-vehicles, spline shaft, and manual tools. The grinding type serration spline rolling dies can be ensured for the precision, delicate and smooth surface, extending the life of the rollers.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

TSCHAN® TKVSG (SEB-design) Construction and design acc. to operation sheet of German Steel Iron Industry SEB 666212 Hub and housing of reinforced material - Additional retainer rings improve axial fixing of the barrel by created axial rope forces General features Torsionally rigid, compensate for angular and axial shaft misalignment Torque transmission by hardened steel rollers For use in crane/ hoist applications to support the rope drum Outer diameters up to 850 mm Wear indication Bores up to 400 mm Torques up to T Kmax = 685,000 Nm FEATURES AND APPLICATIONS TSCHAN TK barrel couplings are recommended for installation in crane lifting mechanisms, to connect the cable drum with the gearbox output shaft, as well as in winch conveyors and platform hoists. By selecting the coupling size (Table 1a/1b in the catalogue), it is necessery to consider the radial load (S T(N)), the dimension of the gearbox shaft (d min – d max) and especially the transmission torque (T) with the...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RINGFEDER POWER TRANSMISSION GMBH

Germany

TSCHAN® TKSG (SEB-design) Construction and design acc. to operation sheet of German Steel Iron Industry SEB 666212 Hub and housing of standard material - Additional retainer rings improve axial fixing of the barrel by created axial rope forces General features Torsionally rigid, compensate for angular and axial shaft misalignment Torque transmission by hardened steel rollers For use in crane/ hoist applications to support the rope drum Outer diameters up to 850 mm Wear indication Bores up to 400 mm Torques up to T Kmax = 685,000 Nm FEATURES AND APPLICATIONS TSCHAN TK barrel couplings are recommended for installation in crane lifting mechanisms, to connect the cable drum with the gearbox output shaft, as well as in winch conveyors and platform hoists. By selecting the coupling size (Table 1a/1b in the catalogue), it is necessery to consider the radial load (S T(N)), the dimension of the gearbox shaft (d min – d max) and especially the transmission torque (T) with the operating...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

TSCHAN TK barrel couplings are recommended for installation in crane lifting mechanisms, to connect the cable drum with the gearbox output shaft, as well as in winch conveyors and platform hoists. General features Torsionally rigid, compensate for angular and axial shaft misalignment Torque transmission by hardened steel rollers For use in crane/ hoist applications to support the rope drum Outer diameters up to 850 mm Wear indication Bores up to 400 mm Torques up to T Kmax = 685,000 Nm FEATURES AND APPLICATIONS TSCHAN TK barrel couplings are recommended for installation in crane lifting mechanisms, to connect the cable drum with the gearbox output shaft, as well as in winch conveyors and platform hoists. By selecting the coupling size (Table 1a/1b in the catalogue), it is necessery to consider the radial load (S T(N)), the dimension of the gearbox shaft (d min – d max) and especially the transmission torque (T) with the operating factor (K1) in Table 3 in the catalogue). Rigid...

Request for a quote

TAS SCHÄFER GMBH

Germany

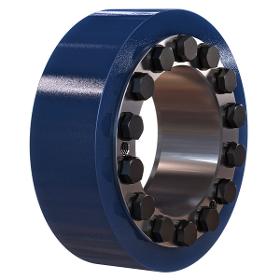

The main function of a shrink disc is the safe connection of a shaft with a hub by means of friction. For example, between a drive shaft and a transmission hollow shaft. The shrink disc generates a backlash-free connection by pressing the hub onto the shaft. This connection is mainly used to transmit torque. The shrink disc only provides the required forces, and transfers no forces or moments between shaft and hub by itself. Therefore, the force flow does not pass through it. It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the screws. By using conical surfaces the inner diameter reduces and the radial pressure is built up. The 30xx range of shrink discs are not self-locking. The clamping forces are provided and controlled through the screws. This allows the direct compensation of the clearance between the shaft and hub, without an overload that may occur on path controlled shrink discs, due to small or over sized clearance. The...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a shrink disc is the safe connection of a shaft with a hub by means of friction. For example, between a drive shaft and a transmission hollow shaft. The shrink disc generates a backlash-free connection by pressing the hub onto the shaft. This connection is mainly used to transmit torque. The shrink disc only provides the required forces, and transfers no forces or moments between shaft and hub by itself. Therefore, the force flow does not pass through it. It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the screws. By using conical surfaces the inner diameter reduces and the radial pressure is built up. The 30xx range of shrink discs are not self-locking. The clamping forces are provided and controlled through the screws. This allows the direct compensation of the clearance between the shaft and hub, without an overload that may occur on path controlled shrink discs, due to small or over sized clearance. The...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a shrink disc is the safe connection of a shaft with a hub by means of friction. For example, between a drive shaft and a transmission hollow shaft. The shrink disc generates a backlash-free connection by pressing the hub onto the shaft. This connection is mainly used to transmit torque. The shrink disc only provides the required forces, and transfers no forces or moments between shaft and hub by itself. Therefore, the force flow does not pass through it. It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the screws. By using conical surfaces the inner diameter reduces and the radial pressure is built up. The 30xx range of shrink discs are not self-locking. The clamping forces are provided and controlled through the screws. This allows the direct compensation of the clearance between the shaft and hub, without an overload that may occur on path controlled shrink discs, due to small or over sized clearance. The...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a shrink disc is the safe connection of a shaft with a hub by means of friction. For example, between a drive shaft and a transmission hollow shaft. The shrink disc generates a backlash-free connection by pressing the hub onto the shaft. This connection is mainly used to transmit torque. The shrink disc only provides the required forces, and transfers no forces or moments between shaft and hub by itself. Therefore, the force flow does not pass through it. It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the screws. By using conical surfaces the inner diameter reduces and the radial pressure is built up. The 30xx range of shrink discs are not self-locking. The clamping forces are provided and controlled through the screws. This allows the direct compensation of the clearance between the shaft and hub, without an overload that may occur on path controlled shrink discs, due to small or over sized clearance. The...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a shrink disc is the safe connection of a shaft with a hub by means of friction. For example, between a drive shaft and a transmission hollow shaft. The shrink disc generates a backlash-free connection by pressing the hub onto the shaft. This connection is mainly used to transmit torque. The shrink disc only provides the required forces, and transfers no forces or moments between shaft and hub by itself. Therefore, the force flow does not pass through it. It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the screws. By using conical surfaces the inner diameter reduces and the radial pressure is built up. The 31xx range of shrink discs are self-locking. The clamping forces are provided and controlled through the screws (force controlled). This allows the direct compensation of the clearance between the shaft and hub, without an overload that may occur on path controlled shrink discs, due to small or over sized...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a shrink disc is the safe connection of a shaft with a hub by means of friction. For example, between a drive shaft and a transmission hollow shaft. The shrink disc generates a backlash-free connection by pressing the hub onto the shaft. This connection is mainly used to transmit torque. The shrink disc only provides the required forces, and transfers no forces or moments between shaft and hub by itself. Therefore, the force flow does not pass through it. It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the screws. By using conical surfaces the inner diameter reduces and the radial pressure is built up. The 30xx range of shrink discs are not self-locking. The clamping forces are provided and controlled through the screws. This allows the direct compensation of the clearance between the shaft and hub, without an overload that may occur on path controlled shrink discs, due to small or over sized clearance. The...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a shrink disc is the safe connection of a shaft with a hub by means of friction. For example, between a drive shaft and a transmission hollow shaft. The shrink disc generates a backlash-free connection by pressing the hub onto the shaft. This connection is mainly used to transmit torque. The shrink disc only provides the required forces, and transfers no forces or moments between shaft and hub by itself. Therefore, the force flow does not pass through it. It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the screws. By using conical surfaces the inner diameter reduces and the radial pressure is built up. The 30xx range of shrink discs are not self-locking. The clamping forces are provided and controlled through the screws. This allows the direct compensation of the clearance between the shaft and hub, without an overload that may occur on path controlled shrink discs, due to small or over sized clearance. The...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a shrink disc is the safe connection of a shaft with a hub by means of friction. For example, between a drive shaft and a transmission hollow shaft. The shrink disc generates a backlash-free connection by pressing the hub onto the shaft. This connection is mainly used to transmit torque. The shrink disc only provides the required forces, and transfers no forces or moments between shaft and hub by itself. Therefore, the force flow does not pass through it. It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the screws. By using conical surfaces the inner diameter reduces and the radial pressure is built up. The 30xx range of shrink discs are not self-locking. The clamping forces are provided and controlled through the screws. This allows the direct compensation of the clearance between the shaft and hub, without an overload that may occur on path controlled shrink discs, due to small or over sized clearance. The...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a shrink disc is the safe connection of a shaft with a hub by means of friction. For example, between a drive shaft and a transmission hollow shaft. The shrink disc generates a backlash-free connection by pressing the hub onto the shaft. This connection is mainly used to transmit torque. The shrink disc only provides the required forces, and transfers no forces or moments between shaft and hub by itself. Therefore, the force flow does not pass through it. It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the screws. By using conical surfaces the inner diameter reduces and the radial pressure is built up. The 30xx range of shrink discs are not self-locking. The clamping forces are provided and controlled through the screws. This allows the direct compensation of the clearance between the shaft and hub, without an overload that may occur on path controlled shrink discs, due to small or over sized clearance. The...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a shrink disc is the safe connection of a shaft with a hub by means of friction. For example, between a drive shaft and a transmission hollow shaft. The shrink disc generates a backlash-free connection by pressing the hub onto the shaft. This connection is mainly used to transmit torque. The shrink disc only provides the required forces, and transfers no forces or moments between shaft and hub by itself. Therefore, the force flow does not pass through it. It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the screws. By using conical surfaces the inner diameter reduces and the radial pressure is built up. The 30xx range of shrink discs are not self-locking. The clamping forces are provided and controlled through the screws. This allows the direct compensation of the clearance between the shaft and hub, without an overload that may occur on path controlled shrink discs, due to small or over sized clearance. The...

Request for a quoteResults for

Transmission shafts - Import exportNumber of results

57 ProductsCountries

Company type

Category

- Potentiometers (12)

- Gears (6)

- Tidal power plants (6)

- Forming, rubber - machinery (2)

- Mechanical transmission - components (2)

- Automobile - assistance (1)

- Axles, vehicle (1)

- Electric motors and parts (1)

- Energy - renewable (1)

- Engine testing and regulating equipment - electronic (1)

- Pinions (1)

- SMALL METAL PARTS (1)

- Screws (1)

- Spare parts for lorries and trailers (1)

- Testing equipment (1)

- Threading tools (1)

- Turning - steels and metals (1)

- Vehicle maintenance products (1)