- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining of sheet metal

Results for

Machining of sheet metal - Import export

TECHNIC MACHINES

Turkey

Our sheet metal Perforating machine is feasible for working different raw material. We provide necessary adjustments on our perforation machine lines according to requested work of our customers for having final perforated sheet results according to our customers or their market demand. Perforated sheet metals is preferred in many different areas and industries. We can say these industries and field such as, electric and electronic, air condition, refrigerator, machinery, automative, filter production, furniture, lighting, shelfs, racks, walking platforms, filers and etc. Perforation Machine Main Units – Press Feeding Unit – Punching Unit – Cutting Unit – Stacking Unit – Recoiling Unit We provide our perforated sheet machine line according to demand of our customers with different perforated sheet working thickness and width etc.

Request for a quote

MICRON AMERICA

Turkey

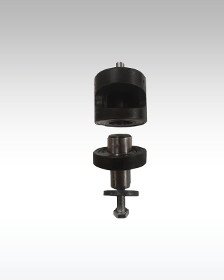

This machine can accommodate every die we manufacture. Simple straightforward design allows even a novice to professionally set grommets, rivets and snaps and Portable design allows you to take it to a job site. Package Deal Includes √ M 3 Grommet Machine √ #8 Sheet Metal Grommet dies with Hole Piercing dies and Teflon board √ 1 bag of #8 Sheet Metal Grommets and Plain Washer (144 pcs of each)

Request for a quote

MICRON AMERICA

Turkey

Sheet Metal Grommets quickly and efficiently with Micron’s industrial die sets. These dies are built to cut and set your sheet metal grommets in a 2 step cutting and setting process without having to change your dies to ease the production time. The dies first punches the hole in the material on the first step, then sets the grommet on the second step. This eliminates the need to swap dies or run concurrent machines. √ 3/8 inch smooth top shaft, 3/4 inch smooth bottom shaft. √ Compatible with the MC 20 fastener attaching machine, intended only for sheet metal grommets. √ These dies are compatible with Stimpson and Scovill grommets.

Request for a quote

MICRON AMERICA

Turkey

Sheet Metal Grommets quickly and efficiently with Micron’s industrial die sets. These dies are built to cut and set your sheet metal grommets in a 2 step cutting and setting process without having to change your dies to ease the production time. The die first punches the hole in the material on the first step, then sets the grommet on the second step. This eliminates the need to swap dies or run concurrent machines. √ 3/8 inch smooth top shaft, 3/4 inch smooth bottom shaft. √ Compatible with the MC 20 fastener attaching machine, intended only for sheet metal grommets. √ These dies are compatible with Stimpson and Scovill grommets.

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is a type of sandblasting machine used mostly for the purpose of sandblasting sheet metal, profile, and steel constructions in the manufacturing sector. The conveyor is manufactured as a roll or wire band depending on the need. Tunnel-type sandblasting machines are primarily preferred for preparation before painting in integrated facilities.

Request for a quote

ILK IHRACAT AS.

Turkey

Shape your parts as desired with our professional machining service. Complete your projects in the best way possible with our precision and quality processing capability. Get a Quote and experience the difference! Our Advantages: Precision Processing: We process your parts with the highest precision to meet your quality standards. Variety of Materials: We have the capability to process various materials like steel, aluminum, cast iron, and more. Customized Solutions: We offer customized machining solutions that align with your technical drawings. Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

TECHNIC MACHINES

Turkey

We design our coil straightener machine for having perfect straightening results and without damage on sheet metal surface. Our coil straightener machines provide to have working possibility with high speed and precision sheet metal straightening results during press feeding. We have as alternative for coil straightener machine standard models. And we design and provide for different request specific coil straightener machines. We supply our coil straightener machines as to our customer's requests and needs, according the working sheet raw material, thickness and width. We check our customer’s final target product and requested production capacity, then we offer the optimum solution coil straightener machine solution.

Request for a quote

TECHNIC MACHINES

Turkey

Our PU, PIR and PUF sandwich panel production machines have different capacity and production thickness from 30 mm to 200 mm and also sandwich panel making machine speed from 6 meters/minute to 16 meters/minute with 50 mm sandwich panel thickness production. Our sandwich panel machine lines are the optimum solution in the market with quality and performance matching parameters. Sandwich Panel Production Line Units Roll Decoiler Machine Feeding Unit Film Coating Unit Roll Forming Machine Rolling Conveyor Unit Pre-Heating Foaming Machine Double Belt Pressing Machine Rolling Conveyer Fly Cutting Unit Runout Table Automatic Vacuum Stacker Automatic Packaging Machine Metal raw material can be changed on sandwich panel machines, as aluminium, metal sheet, pre-painted metal sheets etc.

Request for a quote

BOSPORAS

Turkey

Deformations that are created by utilizing thermal cutting process causes metal materials to lose their flat form. The materials which are cut by a laser, plasma or oxygen cutter that utilize thermal process can become almost impossible to be in a desired flat form again. This is no longer an issue with the new generation leveler technology. Our new generation leveler touches almost every point of the sheet metal material and can smart process. That way, stressed material can be straightened.

Request for a quote

BOSPORAS

Turkey

Our Servo Feeder model allows customers to save energy, space and reduces maintenance costs. AS models don’t need external guidance because they minimize the distance between Press body and the template.

Request for a quote

BOSPORAS

Turkey

Our Mini Servo Feeder model allows customers to save energy, space and reduces maintenance costs. AMS models don’t need external guidance because they minimize the distance between Press body and the template.

Request for a quote

BOSPORAS

Turkey

Our company BOSPORAS, mass produces AMD models with static body and in accordance with Conformité Européenne (CE) regulations. Our understanding of making the “quality” our top priority has made us the top choice among customers. AMD model products are manufactured to work between 0,3 and 3 millimeters of thickness and, 100 and 200 millimeters of width. AMD model consists of 7 rollers that have HRC 58-60 surface stiffness which 5 of them have 60 millimeters diameter and two of them have 80 millimeters of diameter. AMD models don’t need any external guidance because they minimize the distance between Press body and the template.

Request for a quote

HTMACH - HT GRUP MAKINA A.S.

Turkey

HTMACH Turret Punch Press Machine is capable of working large sheet metals with fast axes speed and stroke frequency. It is used high level mechanic and electronic automation equipments in its construction. Machine keeps its compact structure with all its specialties and equipment. All of the components on the machine are world wide known brand names. Capacity is 1225mmX30ton

SEÇ KAMA

Turkey

We are able to progress in different areas of all types of CNC machining, welding, sheet metal processing, etc.Also offer our partners to produce milling, machining, grinding, casting and welding.Our main products are non-standard and standard machine keys.Sec Kama was certificated by TÜV AUSTRIA Company with ISO 9001: 2015 quality management standard.

Request for a quote

NOVELTY STEEL

Turkey

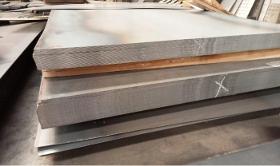

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

ILK IHRACAT AS.

Turkey

Applications of Carbon Steel Sheets The applications of carbon steel sheets are quite extensive. Here are some examples: Construction: Carbon steel sheets are widely used in large construction projects for structural frames, bridges, and more. Automotive Industry: They are employed in the automotive industry for chassis and body components. Maritime: Due to their resistance to seawater, carbon steel sheets are used in shipbuilding. Power Plants: Carbon steel sheets serve as durable coating materials in power plants, withstanding high temperatures and pressures. Advantages of Carbon Steel Sheets Carbon steel sheets offer several advantages: Cost Efficiency: They are more cost-effective compared to other materials. High Strength: Carbon steel sheets have the capacity to withstand heavy loads. Wide Range of Applications: They are adaptable to various applications across different industries. Contact Us for your sheet metal needs.

Request for a quote

ERA ALUMINYUM LTD. CO.

Turkey

TECHNICAL SPECIFICATIONS Long Size SCOPE OF APPLICATION Pitched roofs with trapezoidal sheet metal, sandwich panels Connection to concrete & steel beams. MODULE ORIENTATION Vertical or horizontal ROOF FASTENINGS Concrete ans steel screws Epdm rubber A270 stainless screws ERA clips nut Stainless single bracket ERA locknuts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERA ALUMINYUM LTD. CO.

Turkey

TECHNICAL SPECIFICATIONS Long Size SCOPE OF APPLICATION Pitched roofs with trapezoidal sheet metal, sandwich panels Connection to concrete & steel beams. MODULE ORIENTATION Vertical or horizontal ROOF FASTENINGS Concrete ans steel screws Epdm rubber A270 stainless screws ERA clips nut Stainless single bracket ERA locknuts.

Request for a quote

ERA ALUMINYUM LTD. CO.

Turkey

RAIL LAYER SIZE Short & Long Size SCOPE OF APPLICATION Pitched roofs with trapezoidal sheet metal or sandwich panels MODULE ORIENTATION Vertical or horizontal ROOF FASTENINGS Bimetal selftapping screws with sealing washers Epdm rubber A270 stainless screws ERA clips nut Stainless single bracket

Request for a quote

ERA ALUMINYUM LTD. CO.

Turkey

RAIL LAYER SIZE Short & Long Size SCOPE OF APPLICATION Pitched roofs with trapezoidal sheet metal or sandwich panels MODULE ORIENTATION Vertical or horizontal ROOF FASTENINGS Bimetal selftapping screws with sealing washers Epdm rubber A270 stainless screws ERA clips nut Stainless single bracket

Request for a quote

CERM-EX TECHNOLOGY INDUSTRY AND TRADING INC

Turkey

CERM-EX offers Sheet Metal Design, Fabrication, Manufacturing, Construction, Assembly and Field Installation. We provide comprehensive Metal Working Solutions for all your custom sheet metal fabrication needs. If it can be designed and drawn, if it can be made of metal or metal plate, then CERM-EX can make your drawings a reality. We work with carbon steel, alloy steel, stainless steel, and aluminum sheet metal. Typical products we fabricate from these materials are metal cones, fabricated metal elbows, transitions, cyclones, tanks, compressor skids, industrial belt guards, metal cylinders, coupling guards, troughs, motor base, blower housings, strainer baskets among many other products.

Request for a quote

KEDY

Turkey

Introduce the K5200 Sheet Metal Tong & Sheet Lifter from KEDY. The ultimate solution for safe and efficient handling of large sheets of metal. With a maximum load capacity of 20 tons, it can easily handle even the heaviest sheets of metal. Equipped with remote control, it allows the operator to easily extend and retract the arms of the tong from a distance, making it a convenient and efficient tool for handling large sheets of metal. The sheet metal tong is also designed with safety in mind, it has an emergency stop button, programmable memory, auto-grip and overload protection, ensuring that the operator is always in control. It's compact, lightweight and easy to transport, making it ideal for worksites of all sizes. Upgrade your metal handling operation today with the K5200 sheet metal tong and sheet lifter from KEDY. Contact us today to place your order and experience the benefits of the K5200 sheet metal tong and sheet lifter for yourself!

Request for a quoteResults for

Machining of sheet metal - Import exportNumber of results

24 ProductsCountries

Category

- Sheet metals - stamping (5)

- Cutting - machine tools (4)

- Industrial sheet metal work (2)

- Punching machine tools (2)

- Sheet Metal & Tubes (1)

- Metal straightening machines (1)

- Turning - steels and metals (1)

- Coupling screws (1)

- Lifting equipment (1)

- Metal industrial presses (1)

- Metallurgy - machinery and installations (1)

- Sandblasting equipment (1)

- Screw cutting - steels and metals (1)

- Sheet metal and strips, tinplate (1)

- Steels and metals - machining (1)