- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- manufacture of wall coverings

Results for

Manufacture of wall coverings - Import export

VARDEK VARLIBAS DEKORASYON

Turkey

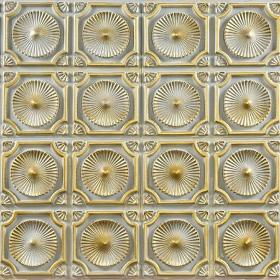

Specially designed for those who want to feel like time-travelling while preferring to experience spatial mobility with dense patterns on their walls or ceiling. Height: 1.25 m Width: 2.50 m Surface Area: 3.12 m2 Weight: 4.5 kg/m2

VARDEK VARLIBAS DEKORASYON

Turkey

FAUX WALL PANEL - STYROFOAM Faux brick wall, faux stone wall and faux wood wall panels are produces with 26-30 DNS 2 cm styrofoam. Panels surface are covered with stone powder, thus they are strong, light, easy application as DIY and help for sound and heat insulation.

VARDEK VARLIBAS DEKORASYON

Turkey

• MATERIAL: Manufactured from polyester, fiberglass and stone dust. • TEXTURE: It gives an identical stone appearance with its look and texture. • WEIGHT/THICKNESS: It has a 5-8 kg/m2 average weight and a 3-5 cm thickness • SIZE: The product size is usually 133 × 285 cm, however, it can vary a few centimetres depending on the model. • UV resistance: It is absolutely not affected by ultraviolet rays. • IMPACT RESISTANCE: It is highly resistant against impacts thanks to its shock absorption feature. • WATER AND MOISTURE RESISTANCE: It is not affected by water and moisture. It can be easily used in places such as kitchens and bathrooms. • HEAT RESISTANCE: Not flammable. It can be used in the places where get intense sunlight or heat exposure. • APPLICATION: It can be easily applied to all surfaces which its rough construction is completed with screws and dowels. • FLEXIBILITY: Oval and moving forms can be given thanks to its flexible structure.

VARDEK VARLIBAS DEKORASYON

Turkey

• MATERIAL: Manufactured from polyester, fiberglass and stone dust. • TEXTURE: It gives an identical stone appearance with its look and texture. • WEIGHT/THICKNESS: It has a 5-8 kg/m2 average weight and a 3-5 cm thickness • SIZE: The product size is usually 133 × 285 cm, however, it can vary a few centimetres depending on the model. • UV resistance: It is absolutely not affected by ultraviolet rays. • IMPACT RESISTANCE: It is highly resistant against impacts thanks to its shock absorption feature. • WATER AND MOISTURE RESISTANCE: It is not affected by water and moisture. It can be easily used in places such as kitchens and bathrooms. • HEAT RESISTANCE: Not flammable. It can be used in the places where get intense sunlight or heat exposure. • APPLICATION: It can be easily applied to all surfaces which its rough construction is completed with screws and dowels. • FLEXIBILITY: Oval and moving forms can be given thanks to its flexible structure.

NMSG GRUP ITH. IHR. SAN. VE TIC. LTD. STI

Turkey

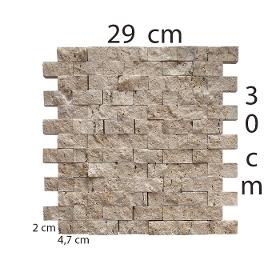

The product is handcrafted. Product dimensions are 29 cm x 30 cm (11.42 inches * 11.81 inches). There are 6 pieces (29cm*30cm) in the package. Product weight single 2 kg, package weight 12 kg 1 package of product covers 0.5 m2 area. Our products are produced from 100% Natural Stone, are easy to lay with a net, and are delivered as a package. Wall Application: Our split face travertine and split face marble products are made entirely of Natural Stone, do not contain any additives and are very easy to apply. Natural stone silicone should be used on wooden surfaces, lightly tapped on the wall on plastered or painted surfaces, black for dark colors and white ceramic adhesive for light colors. Natural Stone varnish or preservative can be used to achieve a more vivid appearance on yellow and rustic colored stones.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZAFER RUBBER

Turkey

Grounding is actually present in nature for millions of years. The grounding system is based on the use of ground and equipment together. The jointing of the floor with the special adherent steel reinforcement creates a friction between the material and the contact surface. Stresses generated in the ground mass are covered by special galvanized steel strip equipment. These stresses are transferred to the strips by friction. Thus, these two materials create a single and composite construction material.

Request for a quoteResults for

Manufacture of wall coverings - Import exportNumber of results

7 ProductsCountries

Company type