- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water treatment systems for the meat industry

Results for

Water treatment systems for the meat industry - Import export

ENKI WATER TREATMENT TECH. LTD

Turkey

A "CO2 degasser" (degassifier) is a relatively simple water treatment device. Incoming water is sprayed into a tower filled with packing material. The drops of water that flow down through the tower strike the packing material and form a thin film on the packing material surface, encouraging the release of excess carbon dioxide. A centrifugal fan creates an updraft of air through the tower to carry away the released carbon dioxide gas. The carbon dioxide gas exits through a vent at the top of the unit.

ENKI WATER TREATMENT TECH. LTD

Turkey

enki’s package water treatment plant (Compact water unit) is used to treat surface water supplies for the removal of suspended solid, color and coliform with classical water treatment process. Our package water treatment plant is pre-assembled in factory and ready to the site. Package water treatment plant is a compact and standardized unit for treated water demands of the small communities and industries. The plant capacity can be increased by adding skid mounted containerized modules. Package water treatment plant is mainly consisting of : coagulation, lamella clarifier, filtration, chemical dosing unit , control panel auxiliary equipment. All equipment will be mounted in the container or in skid. At site will be mounted the piping and electrical cabling between container.

ENKI WATER TREATMENT TECH. LTD

Turkey

Reverse osmosis is the finest level of filtration available. The reverse osmosis membrane acts as a barrier to all dissolved salts and inorganic molecules, as well as organic molecules with a molecular weight greater than approximately 100. Water molecules, on the other hand, pass freely through the membrane creating a purified product stream. Rejection of dissolved salts is typically 95% to greater than 99%. Classification of brackish water: • Low salinity brackish waters: up to 5.000 ppm • High salinity brackish waters: between 5.000 - 15.000 ppm • Sea water: up to 45.000 ppm Reverse osmosis is a technology that is used in the production of ultrapure water for use in the semiconductor industry, power industry (boiler feed water), and medical/laboratory applications. Utilizing reverse osmosis prior to ion exchanger dramatically reduces operating costs and regeneration frequency of the Ionen exchanger plant.

ENKI WATER TREATMENT TECH. LTD

Turkey

When is used an activated carbon filter? Activated carbon filters are very similar to multi media filters and other pressure filters in construction and operation. The purpose of an activated carbon filter is to remove free chlorine, an oxidizing agent that will damage most resins and/or membranes in a water treatment system. A chemical injection system using sodium bisulfite (a reducing agent) can be used in place of an activated carbon filter to remove chlorine. Granular activated carbon is a particularly good adsorbent medium due to its high surface area to volume ratio. One gram of a typical commercial activated carbon will have a surface area equivalent to 850-1.000 square meters. This high surface area permits the accumulation of a large number of contaminant molecules. Some drinking water may be disinfected with chlorine or chloramines.

ENKI WATER TREATMENT TECH. LTD

Turkey

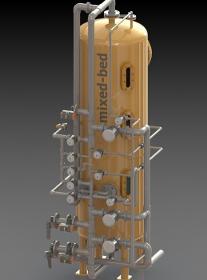

Both cation and anion resin can be feed in to an ion exchanger tank and mixed to create a mixedbed ion exchanger. A mixedbed ion exchanger is more complicated than other types of ion exchangers because it has to separate and regenerate the two resins. The carefull mixing of the cation and anion resin allows a very high degree of deionization. Mixed bed ion exchangers produce the highest quality demineralized water of any of the ion exchanger units. Working mixedbed ion exchangers deionize water with up to 50 ppm TDS (Total Dissolved Solids). Polishing mixedbed ion exchangers are located after cation and anion exchangers or reverse osmosis units Strong acid cation and strong base anion resins are used in mixedbed ion exchangers, as complete demineralization is the objective. A small volume of inert resin can also be used to facilitate separation of the cation and anion resin beads during regeneration

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Water treatment systems for the meat industry - Import exportNumber of results

5 ProductsCountries

Company type