- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal work

Results for

Metal work - Import export

FATIH WROUGHT IRON

Turkey

Weight: 0,35 kg Height : 20 cm Width : 20 cm Material: 2 mm

Request for a quote

RAPTOREX CNC

Turkey

Product comes with 500 watt Arel AC Monophase Spindle with manual and computerized control. Working area is 340x360x126(mm). The frame is made of aluminum and the device can cut pieces up to 240x360x115 (mm) with precision and without any displacement. All types of wood, plastics (ex: POM.), soft metals (ex: aluminum), hard metals (ex: iron, brass) can be processed. Product is suitable for PCB milling. Axis precision is 0.03mm. Spindle bit holder is ER-16. X and Y axis speed is 2400mm/min and Z axis is 1200mm/min. Linear movement is done by three nema 23 step motor. Step motors are controlled by TB6600 drivers with 24volt PS. Control card is MKS DLC. V2.1. Raptorex Pro requires computer connection to operate and is compatible with both open source and paid software. Product works with GRBL codes. Net weight is 39kg. Our device works silent and does not create vibrations. You may use our device on most regular tables. Product comes ready to operate, you may plug in and start operating.

Request for a quote

CIMES HOME

Turkey

RACK CLAD BUILDING SYSTEMS Rack Clad Building Systems eliminates the roof and exterior siding needs of the warehouse and allows you to install a racking system. It eliminates roof and exterior siding needs and allows you to have a construction free racking system. Building construction is not necessa in advance with Rack Clad Building System. Rack Clad Building Systems does not require construction investment, providing a cost advantage from 18% to 30%. Since the use of columns and beams eliminated with the Rack Clad Building Systems, more space gained. Since the Rack Clad Building Systems are in demounted structure, it can easily be mobilized to another place and assembled. Corridor distances in building-free racking systems can be altered depending on type of loading equipment used. In the Rack Clad Building Systems, concrete is applied on the land/ shelves are xed on it, then exterior su ace is constructed by the facade covering (sandwich panel).

Request for a quote

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

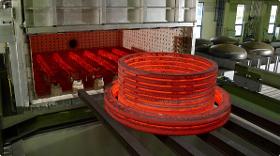

Our Heat Treating Suppliers are certified by Aeronautical and Automotive Industries. Annealing Normalizing Stress Relieving Quenching and Tempering Vacuum Hardening Homogenization Decarburization Nitriding Carburization Case Hardening and more

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 0,91 kg Height: 10 cm Width: 200 cm Material: 0,7 mm

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 17,27 kg Height: 200 cm Width: 100 cm Material: 1.1 mm

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is a contract fabricator of bespoke structural steel works comprising metal cutting, bending, machining, welding and painting. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for plant constructions such as Bulk Handling Equipment, HRSG plants, Steel and Wood Industries. Some examples of the fabrications are: Steel Silos and tanks Inlet Ducts and Silencers Stair Towers Bunkers and Hoppers Pipe Supports Exhaust Stacks Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for plant constructions such as Bulk Handling Equipment, HRSG plants, Steel and Wood Industries. Some examples of the fabrications are: Steel Silos and tanks Inlet Ducts and Silencers Stair Towers Bunkers and Hoppers Pipe Supports Exhaust Stacks Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel metal prefab hangars are durable, waterproof structures for all types of rotorcraft, gliders, jets, and other aircraft. Designed to withstand nature at her worst, pre-engineered buildings promise built-in resistance to earthquake, fire, lightning, snow and wind damage. Customize your helicopter hangar with mezzanine and stairs, overhead cranes, vents, gutters, or skylights and wall lights— whatever you need to make the building ideal for your helicopter or other aircraft. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by an experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel Designs and manufactures various steel frames for various structures and machinery. We produce bespoke steel frames based on the client drawings and preferences. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

The design of steel buildings is influenced by many factors, including new requirements for sustainability, and thermal and acoustic performance. The pressure for more efficient and sustainable construction processes to meet these requirements has led to a demand for higher ratios of off-site fabrication and improved quality in the performance of the chosen construction technology. Steel construction have reached a high market share in not only industrial buildings but also residential and commercial buildings, where the main advantages include: construction pace, high quality, reliability and longevity, and space usage. The majority of structural steelwork is manufactured in the steel contractor’s workshops with very little on site work required which leads to fast construction times. Unlike concrete, steel frames gain full strength when their fabrication is completed, allowing the following construction trades to continue.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for plant constructions such as Bulk Handling Equipment, HRSG plants, Steel and Wood Industries. Some examples of the fabrications are: Steel Silos and tanks Inlet Ducts and Silencers Stair Towers Bunkers and Hoppers Pipe Supports Exhaust Stacks Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for plant constructions such as Bulk Handling Equipment, HRSG plants, Steel and Wood Industries. Some examples of the fabrications are: Steel Silos and tanks Inlet Ducts and Silencers Stair Towers Bunkers and Hoppers Pipe Supports Exhaust Stacks Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVELTY STEEL

Turkey

Metal Brackets are used as support elements for structural stability and load bearing capacity. * Angle Brackets * Flat Brackets * U Shaped Brackets * Z Brackets * T Brackets * Custom Brackets

Request for a quote

NOVELTY STEEL

Turkey

Plasma cutting operates by firing an electrically ionised heated gas (plasma) out of a nozzle at a high speed towards the metal. This will form an electrical ark within the gas. High level of heat is generated as electricity from the nozzle travels down this plasma. This heat melts the metal where cutting is achieved. Plasma cutters can cut stainless steel, aluminium, brass and copper along with mild steel. It’s particularly ideal for thick metal, up to 50 mm. If cutting highly reflective or very thick sheets of metal is required, plasma should be the ideal cutting method. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Carbon Steel and Stainless Steel Robot Laser Welding Part Manufacturing

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Laser cutting is a cutting process which enables cutting metallic and non-metallic materials with different thicknesses for metal fabrication works. The cutting operation is based on a laser beam which is guided, formed, and bundled. While traditional metal cutting processes involve applying large-scale tools with enormous power to the metal, the laser beam completes its task without any direct contact to the work piece. This prevents any wearing, deformation and damage to the tool and the work piece. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

BASAK LAZER

Turkey

Please contact us for detailed information and offer.

Request for a quote

BASAK LAZER

Turkey

Argon welding is the word “Tungsten Inert Gas” that gives the welding method its name. Welding is also called the initials of this word and is referred to as TIG welding. The heat to perform the welding process is generated between the electrodes made of tungsten metal, which has a very high melting point, and the parts to be welded. The welding zone is protected by argon or helium gas sent from a nozzle surrounding the electrode. The electrodes used in the Tig (argon) welding method allow to join the welded material by melting, without melting themselves. When deemed necessary, additional welding rods are delivered to the welding area by the welder or by automatic wire feeding devices, as in oxy gas welding. Argon gas is generally used as a shield in argon welding. Argon gas is a noble gas, so it does not react and provides strong protection. It optimizes the ignition characteristics and stability of the arc

Request for a quote

BASAK LAZER

Turkey

Aluminum is a light, thin metal that is very commonly used in welding shops. With this metal, welding must be done at low temperatures, otherwise pores will form in your materials. Aluminum is highly reactive, so it forms an oxide layer when exposed to air. This oxide is a barrier to welding. Before welding you need to remove the oxide layer using a wire brush. Each different type of weld requires different equipment and techniques, but when you apply everything involved, your aluminum welds look clean and smooth and are very durable.

Request for a quote

BASAK LAZER

Turkey

We offer welded construction solutions using gas metal arc, argon, MIG, TIG and Laser welding technology according to the requirements of our customers. Welding is the process of joining two or more materials with the effect of heat and/or pressure, with or without the use of additional materials. In addition to the joining process, the welding process is used in coating and filling processes. Today, there are many different welding methods. It is a type of process that is used extensively in the industry. Welded manufacturing is defined as a special process in international standards. For this reason, there are international standards in order to guarantee and level the quality level in welded manufacturing.

Request for a quote

BASAK LAZER

Turkey

Wrought Iron Usage Areas are quite wide. Wrought iron means wrought iron. The Turkish equivalent of the French word “Fer forge” means wrought iron. Iron has been used in many different fields since its existence. In the Middle Ages, man discovered the artistic side of iron and turned the cold iron into art by heating it with fire. The main reason why wrought iron is often preferred is that it is durable and aesthetically pleasing to the eye. As for the alternative of wrought iron, we can say that the answer is laser cut wrought iron. Wrought Iron Usage Areas: usually window railing, stair railing,

Request for a quoteResults for

Metal work - Import exportNumber of results

88 ProductsCountries

Category

- Welding work - steels and metal (39)

- Industrial sheet metal work (28)

- Metal structural work (15)

- Cutting - steels and metals (3)

- Clock and watch supplies (3)

- Shearing machine tools (3)

- Machine tools, metal machining - parts and accessories (2)

- Steels and metals - forming and cutting (2)

- Casting, steel (2)

- Laser - cutting and welding machines (1)

- Autogenous welding machines (1)

- Bending - steels and metals (1)

- Metal construction, lightweight (1)

- Sheet metals - stamping (1)

- Cutters (1)

- Punching machine tools (1)

- Stairs, metal (1)

- Steels and metals - welding and brazing (1)

- Aluminium and aluminium alloys (1)

- Aluminium coatings (1)