- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water treatment system

Results for

Water treatment system - Import export

ADVANCED ENGINEERING WEDGE WIRE

Turkey

Intake screen also called T-screen is used to intake and clear water in many industrial areas. They are commonly used in hydroelectric, agricultural, drinking applications to prevent dirty materials from the water. Intake screen is commonly used in lakes known as lake pump intake screen. Intake water works as passive intake screen to intake of water for generating electricity for hydropower. Water intake filter screens can intake clean water by eliminating unwanted materials. Because of its simple cleaning, major maintenance is not required for the operational time. Advantages: 1-High performance water filtration 2-Fish friendly 3-Corrosion resistance 4-Passive intaking water 5-High durability – less maintenance 6-Easy to install Applications: 1-Hydropower Intake 2-Lake Application 3-River Application 4-Water Cleaning

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Advantages 1-Special surface treatment 2-Centrifugal customizable basket design 3-Corrosion resistance 4-Durable and long service life 5-Precise filtration 6-Strong mechanical properties Applications 1-Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. 2-Mining Applications 3-Water Treatment 4-Chemical Fertilization 5-Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with high efficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths. Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages 1-Special filtration 2-Counterbore and customized filtration holes 3-Corrosion resistance 4-High durability – long service life 5-Precisely drilled holes 6-Special surface treatment Applications 1-Sugar Pulp Pressing 2-Water Filtration 3-Paper Mills 4-Pressing 5-Processing of Chemicals 6-Seperation Process

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. Advantages 1-Special surface treatment 2-Modular and customizable design 3-High durability 4-Suitable for heavy applications 5-Superior filtering with unique screen 6-Long service life & less maintenance Applications 1-Coal and Gold Mining Filtration 2-Mineral Processing 3-Water Treatment 4-Petrochemical Applications 5-Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The flat screen also called panel screen is a rectangular type wedge wire screen for filtration. Thus, the shape of the flat screen helps the filtration process complete accurately by vibration or flow. Panel wedge screen panels provide efficient filtration for different applications with suitable geometry. With the portable design of the panel wedge wire screen, it adapts to a wide range of applications with straight geometry. Advantages 1-Special surface treatment 2-Suitable & customizable design 3-Long service life 4-High durability – less maintenance 5-Effective filtration Applications 1-Food and Mineral Processing 2-Water Cleaning 3-Mining Applications 4-Vibrational Separation 5-Fermentation 6-Water Treatment Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the V-wires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easy to use and easy to clean compared to the other wedge wire types Advantages 1-Special surface treatment 2-Portable customizable design 3-Corrosion resistance 4-Efficient filtration Applications 1-Water Treatment 2-Water intake 3-Food processing 4-Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: 1-High filtration performance 2-Customized bend screen design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap 6-High capacity compared to panel wedge wire screen Applications: 1-Mining process 2-Water treatment 3-Food processing 4-Particle filtration 5-Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The wedge wire cylinder screen is the most popular screen that can be adapted to many applications. The shape of the cylindrical screen helps the filtration process complete accurately. It is also called Johnson Screen in some applications. With the modular design of the cylindrical screen, it provides efficient filtration performance for many applications. In addition, cylinder wedge wire screens can rotate or remain static depending on your application. Advantages: Cylinder screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the cylindrical screen are listed below as: 1-Special surface treatment 2-Modular and customizable design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap Applications: 1-Water Treatment 2-Mine, coal, mineral Processing 3-Food and Beverage 4-Petrochemical and oil

Request for a quote

ATMOSFER MACHINERY

Turkey

Reverse Osmosis (RO) systems are renowned for their exceptional water purification capabilities, effectively reducing up to 99% of contaminants. The RO series we specialize in is tailored to meet the demanding needs of industrial water treatment across various sources, including brackish, surface, and municipal water supplies. These industrial reverse osmosis water treatment systems are engineered with upgraded materials and high-capacity technology, making them well-suited for applications in diverse industries. Notably, these systems are uniquely designed and manufactured in the United States, emphasizing energy efficiency and eco-friendliness while consistently delivering high-quality water.

Request for a quote

DENIMTEK TEKSTIL VE TICARET LIMITED ŞIRKETI

Turkey

Denimtek has a wide experience with the new Denim Mill Investment projects. We are preparing a full report for a new mill with the all machinery and lay out drawings . We design state of art process lines which will fit to your Target Market and Budget. >Spinning and Weaving Department Design >Rope Dyeing Machine Design >Slasher Machine Design >Sizing Machine >Complete Finishing Design >Coating Machine Design >Waste Water Treatment Systems >Water Treatment Systems >Reverse Osmosis Systems >Fire Extinguishing Systems

Request for a quote

TURKOGLU

Turkey

Body : GG-25 Cast Iron (EN GJL 250) / Disc : Ductile Iron+ Nickel Coated / Handwheel : Ductile Iron+ Nickel Coated / Shaft : Stainless Steel / Gasket : EPDM-NBR-PTFE-VITON / Connection : Flanged (Wafer Type) / Max. Working Temp. : 110 ºC / Max. Working Pressure : 16 Bar *** Applications Area : HVAC Systems / Water Treatment Systems / Paper Industry / Fresh Water System

Request for a quote

TURKOGLU

Turkey

Body : GG-25 Cast Iron (EN GJL 250) / Disc : Ductile Iron+ Nickel Coated / Handwheel : Ductile Iron+ Nickel Coated / Shaft : Stainless Steel / Gasket : EPDM-NBR-PTFE-VITON / Connection : Flanged (Lug Type) / Max. Working Temp. : 110 ºC / Max. Working Pressure : 16 Bar *** Applications Area : HVAC Systems / Water Treatment Systems / Paper Industry / Fresh Water System

Request for a quote

ENKI WATER TREATMENT TECH. LTD

Turkey

Reverse osmosis is the finest level of filtration available. The reverse osmosis membrane acts as a barrier to all dissolved salts and inorganic molecules, as well as organic molecules with a molecular weight greater than approximately 100. Water molecules, on the other hand, pass freely through the membrane creating a purified product stream. Rejection of dissolved salts is typically 95% to greater than 99%. Classification of brackish water: • Low salinity brackish waters: up to 5.000 ppm • High salinity brackish waters: between 5.000 - 15.000 ppm • Sea water: up to 45.000 ppm Reverse osmosis is a technology that is used in the production of ultrapure water for use in the semiconductor industry, power industry (boiler feed water), and medical/laboratory applications. Utilizing reverse osmosis prior to ion exchanger dramatically reduces operating costs and regeneration frequency of the Ionen exchanger plant.

ENKI WATER TREATMENT TECH. LTD

Turkey

When is used an activated carbon filter? Activated carbon filters are very similar to multi media filters and other pressure filters in construction and operation. The purpose of an activated carbon filter is to remove free chlorine, an oxidizing agent that will damage most resins and/or membranes in a water treatment system. A chemical injection system using sodium bisulfite (a reducing agent) can be used in place of an activated carbon filter to remove chlorine. Granular activated carbon is a particularly good adsorbent medium due to its high surface area to volume ratio. One gram of a typical commercial activated carbon will have a surface area equivalent to 850-1.000 square meters. This high surface area permits the accumulation of a large number of contaminant molecules. Some drinking water may be disinfected with chlorine or chloramines.

ENKI WATER TREATMENT TECH. LTD

Turkey

Media filter is used to reduce the level of suspended solids (turbidity) in feed water. Suspended solids consist of small particles such as silt, clay, grit, organic matter, algae and other microorganisms. Feed water that is high in suspended solids can cause a high pressure drop and reduce the effectiveness of downstream equipment such as reverse osmosis membranes and ion exchange beds.

ENKI WATER TREATMENT TECH. LTD

Turkey

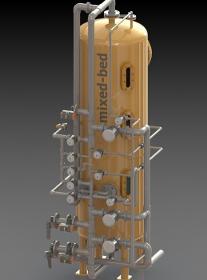

Both cation and anion resin can be feed in to an ion exchanger tank and mixed to create a mixedbed ion exchanger. A mixedbed ion exchanger is more complicated than other types of ion exchangers because it has to separate and regenerate the two resins. The carefull mixing of the cation and anion resin allows a very high degree of deionization. Mixed bed ion exchangers produce the highest quality demineralized water of any of the ion exchanger units. Working mixedbed ion exchangers deionize water with up to 50 ppm TDS (Total Dissolved Solids). Polishing mixedbed ion exchangers are located after cation and anion exchangers or reverse osmosis units Strong acid cation and strong base anion resins are used in mixedbed ion exchangers, as complete demineralization is the objective. A small volume of inert resin can also be used to facilitate separation of the cation and anion resin beads during regeneration

Do you sell or make similar products?

Sign up to europages and have your products listed

ENKI WATER TREATMENT TECH. LTD

Turkey

enki’s package water treatment plant (Compact water unit) is used to treat surface water supplies for the removal of suspended solid, color and coliform with classical water treatment process. Our package water treatment plant is pre-assembled in factory and ready to the site. Package water treatment plant is a compact and standardized unit for treated water demands of the small communities and industries. The plant capacity can be increased by adding skid mounted containerized modules. Package water treatment plant is mainly consisting of : coagulation, lamella clarifier, filtration, chemical dosing unit , control panel auxiliary equipment. All equipment will be mounted in the container or in skid. At site will be mounted the piping and electrical cabling between container.

ENKI WATER TREATMENT TECH. LTD

Turkey

In comparison to conventional water treatment processes, the advantage of "ultrafiltration" as a filter technology is its superior ability to remove germs and microorganisms from water. At around 20 nm, the pores of the membrane are small enough to prevent even viruses from passing through them. "Ultrafiltration" systems are designed for fully automatic operation. A control mechanism is used to control the various operating modes of the ultrafiltration process: filtration, cleaning and backwashing. enki’s industrial ultrafiltration units are available from 25 to 500 m3/h and more . Our ultrafiltration systems are available in either Outside-In or Inside-Out configurations. Outside-In configuration UF Systems; DOW H-PVDF Hollow Fiber UF Membranes Inside-Out configuration UF Systems; Inge PESM Hollow Fiber UF Membranes

ENKI WATER TREATMENT TECH. LTD

Turkey

A "CO2 degasser" (degassifier) is a relatively simple water treatment device. Incoming water is sprayed into a tower filled with packing material. The drops of water that flow down through the tower strike the packing material and form a thin film on the packing material surface, encouraging the release of excess carbon dioxide. A centrifugal fan creates an updraft of air through the tower to carry away the released carbon dioxide gas. The carbon dioxide gas exits through a vent at the top of the unit.

BIMAKS KIMYA VE GIDA DIS TIC. LTD. STI.

Turkey

GENERAL DESCRIPTION MAKS 3000 is a non-chromate film-forming product in liquid form. PRINCIPAL USES MAKS 3000 provides maximum protection for mild steel, copper and yellow metals in closed cooling systems fed with distilled, demineralized or softened water. MAKS 3000 is widely applied in closed cooling systems of steel mills, power stations, refineries and many other industrial plants. PRODUCT BENEFITS Extends equipment life and reduces maintenance costs Environmentally friendly; does not contain heavy metals Compatible with antifreeze

Request for a quote

KEMISAN KLOR-ALKALI A.Ş.

Turkey

LX Series is an industrial-level HypoX Sodium Hypochlorite Generator line with a wide capacity range that answers all industrial water disinfection requirements. LX Series is generally used for large-scale water disinfection requirements of municipality drinking water treatment facilities, swimming pools and aqua parks, large-sized industrial process water disinfection, and cooling tower. With its own chemical synergy of Fresh and Mix Oxidants besides hypochlorite, HypoX® LX Series guarantees to solve important problems like Biofilm, Odor, Legionella, and Strong Pathogens. The high disinfection performance of HypoX® LX Series makes it an effective, economic, green, and safe alternative mainly to chlorine and other biocides in chlorination requirements Applications Areas - Large scaled drinking water&wastewater treatment plants - Swimming pools and aquaparks - Industrial process water treatment - Cooling towers - Reverse Osmoses Process water

Request for a quote

TRADEGE FOREIGN TRADE AND CONSULTING

Turkey

Aluminum sulphate has a very important place in food, health, water treatment, fertilizer, feed industry and industrial production. Drinking water treatment is the most common use. Because it is a very good filtering agent, it is used for the process of removing undesired material from the environment by collapsing the production process. As a pH regulator in agriculture it helps to enrich the soil with mineral.

Request for a quoteResults for

Water treatment system - Import exportNumber of results

24 ProductsCountries

Company type

Category