- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- condensers

Results for

Condensers - Import export

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Five Stage and Six stage Steam Jet Ejectors with Condenser Five stage and six stage ejectors are designed for absolute pressure in Micron Range. The arrangement of these ejectors is similar to the four stage ejector with additional one or tow non condensing stages. Special Precautions while measuring Low Absolute Pressures : Do not use spring type vacuum Gauges Ensure that the guage tubes are clean and free form contamination Ensure that the guage liquid is clean and free from contamination

Request for a quote

CDS GROUP MARINE & INDUSTRIAL

United Kingdom

Carrier Condenser Coil to NLNG (Nigeria Liquefied Natural Gas) specifications and complete with BLYGOLD protection.

Request for a quote

CDS GROUP MARINE & INDUSTRIAL

United Kingdom

Carrier Condenser Coil to NLNG (Nigeria Liquefied Natural Gas) specifications and complete with BLYGOLD protection.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

When it comes to the performance of a turbine surface condenser in the operational field of a steam turbine cycle, you need utmost reliability and efficiency. Here’s where Jet Flow’s know how is invaluable. We createcustomise package solutions for each particular customer’s needs. Our General Scope of Supply Condenser Circular Condenser having own Flow, Axial flow or side inlet steam entry. Turbine to Condenser steam duct, including necessary expansion joints. Steam Jet Ejector Vacuum System. Flash tank, drain header and Instrument stand pipe. Dump Tube. Condensate Pump system Pumps are in vertical or horizontal arrangement; either API 610, ISO 5199 or standard manufacturer pump design. Control system Including level control valves pressure and temperature indicators, transmitters and controllers. Interconnecting piping with filter, fittings and valves.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The Steam Surface condenser is a critical component of both the traditional coal fired power plant and the new generation cogeneration and combined cycle power plants. Main duties of any Surface Condenser are to convert the exhaust steam from its gaseous to its liquid state at certain under atmospheric pressure, and also, to release non condensable presented in the steam cycle, together with vacuum unit. Jet Flow designs and economically sized condenser suitable for smaller turbine ratings under 100 MW. The circular configuration is compact for easy shipping and maintains the level of quality afforded all of our condenser designs. All of Jet Flow’s Surface Condensers are designed and built to the Heat Exchange Institute latest Standards. We also strive to meet all of our client’s project specific requirements.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Condenser Tube Brush

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Gland seal systems very important to main and auxiliary turbines. Turbine shafts must exit their casings in order to couple up or connect with the unit that the turbines drive (reduction gears, pumps, etc.) The main and auxiliary gland seal systems enable the turbine to be sealed where the shaft exits the casing; in effect keeping "air out and steam in." The purpose of gland seal system is to prevent the leakage of air from the atmosphere into turbine casings and prevent the escape of steam from turbine casings into the atmosphere. The gland sealing system provides low pressure steam to the turbine gland in the final sets of labyrinth packing. This assists the labyrinth packing in sealing the turbine to prevent the entrance of air into the turbine, which would reduce or destroy the vacuum in the associated condenser. Excess pressure (excess gland seal) is removed by the gland seal unloader. Since there are times when steam escapes from the seals, a gland exhaust system is provided.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Four Stage Ejector with Condenser Four Stage Ejector is having construction and working similar to Single Stage, Two Stage & Three Stage Ejector. When ejector is to be installed at low ambient temperature area, primary booster should be steam jacketed to prevent building up of ice on the diffuser internal bore. Sometimes both primary and secondary boosters are completely jacked to avoid deposition of product inside the ejector. The Four Stage Ejector consists of following components Primary Booster Ejector Secondary Booster Ejector Booster Condenser Vacuum Ejector Inter Condenser Low Vacuum Ejector

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Three Stage Ejector is similar in construction as of Single Stage Ejector, but having intermediate condensers. Three Stage Ejector comprises of Booster Ejector, Booster condenser and a Two Stage Ejector. And Two Stage Ejector consists of a high vacuum ejector, a inter condenser and a low vacuum ejector. This system will give higher vacuum and can handles larger quantity of condensable vapors. Gas or Gas vapor mixture is discharged from the first stage into the condenser where the operating steam is condensed and gases are cooled. The cooled gases are then entrained by the second stage and discharged into the second inter condenser. Here, the steam used in the second stage is condensed. The gases are finally entrained by the third stage and discharged to atmosphere.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

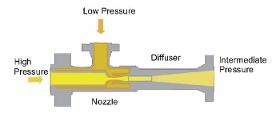

SingleStage Steam Jet Ejectors are based on the ejectorventuri principle. In operation, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy. A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure. Single stage steam jet ejectors are used to create vacuum covering 40 mm Hg. Absolute. Two Stage Ejector with Condenser The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type). Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The efficiency of a Steam turbine is mainly determined by the pressure of the steam at its outlet. The Turbine Surface Condenser is therefore maintained under vacuum. To enable this, the Steam Jet Ejector Vacuum System must be capable of removing all non condensable and associated water vapour from the Surface Condenser to produce the minimum steam condensing pressure consistent with physical dimensions and heat transfer and to provide for deaeration of the condensate. The sources of non condensables include air leakage through all system components operating below atmospheric pressure, gases released from feedwater drains and vents admitted to the condenser, gases released for makeup admitted to the condenser, condensate surge tank when utilized in a closed cycle and disassociation of feedwater into oxygen, hydrogen and non condensables.

Request for a quote

DC PRODUCTS

United Kingdom

Finish: Light grey Seven auto programmes; four timed programmes Sensor-controlled auto programmes stop drying when clothes are dry Dryer can be mounted on washing machine LCD display and interface on local language (13 languages) Reversible door (right/left) Manual or automatic drainage of condensation water – drain hose included Stacking brackets for column installation included Connection: 230V / 1ph / 13A / 50Hz / Max effect: 2.8kW Can be reconfigured to: 230V / 1ph / 10A / 50Hz / Max effect: 2.25kW Condenser dryer

Request for a quote

LONGSUN CORPORATION LTD

United Kingdom

Model No.: BO4015L-423; Technical parameter: Dimension: 4.0*1.5mm. Sensitivity @1KHz: -42 ± 3dB; SNR: >58 dB; Terminal: soldering; SPL: 110 dB; Impedance: 2.2 (Max) KΩ; Voltage: 1.0~10V; Current: <500μA; Directional: Omni-directional.

Request for a quote

LONGSUN CORPORATION LTD

United Kingdom

Model No.: MD23H9-H; Technical parameter: Sensitivity at 1KHz: -66 ± 3dB; AC impedance at 1KHz: 35~80 ohms; Resistance: 180 ± 50 ohms; Frequency range: 200~4000Hz.

Request for a quote

POREFILTERUK LTD

United Kingdom

PVH range of single and multi-cartridge industrial housings is suitable for industrial liquid applications. The standard high flow filter housing can be configured to accept between 1 to 7 high flow cartridges and caters for flows more than 200 m3/hr up to 1,400 m3/hr. Pressure rated to 10bar, the housing is leg mounted. A single high flow housing replaces a multi-round holding 8 to 10 cartridges. The housings are available in vertical or horizontal orientation to make installation of high flow cartridges as easy as possible. Housings are supplied 40” and 60” lengths to maximise cartridge surface area available.

Request for a quote

MARGIELA GROUP S.R.L .

United Kingdom

We are offering Nido Milk Powder / Nestle Nido Fortified 400g 900g 1800g 2500g . Texts available in English, French, Arabic. Nido Milk powder - 400 g, 900 g. 1800 g, 2500 g Nestle Nido Fortified Milk powder - 400 g, 900 g,1800 g, 2500 g Nido Milk powder 400g tin - 24 pcs Nido Milk powder 900g tin - 12 pcs Nido Milk powder 1800g tin - 6 pcs Nido Milk powder 2500 g tin - 6 pcs For further details and queries, feel free to contact us using our website https://www.corporationbv.com

Request for a quote

C2 SALES EQUIPMENT

United Kingdom

Cooling Tower. Evaporative condenser build in FRP

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Condensers - Import exportNumber of results

18 ProductsCountries