- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hydraulics

Results for

Hydraulics - Import export

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Turbine bypass valves play a very major role in Power Plant applications. Within a short period of twenty four hours, a power plant may be required to operate at minimum load, increase to maximum capacity for major part of the day, immediately lower back to minimum load and then back to maximum capacity. Bypass System permit unit start up and shutdown in a lifesaving manner for critical heavy components in boiler and turbines. Jet Flow Bypass valves are supplied with hydraulic, electric or pneumatic actuators as per the process requirements alongwith complete control systems as an option.

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Interchangeable to MIL-C-51234 • Snap-Tite H/IH and Faster TNV/TNL Materials: • Machined components are manufactured using solid Steel, Brass, or 316 Stainless Steel bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome • Steel coupler sleeves are hardened to resist deformation and maximise service life • Steel nipples are machined from high-strength Steel and induction hardened • Tubular ‘TV’ valves are constructed from Steel bar stock and are designed for optimum performance in pneumatic applications Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F) • All couplers incorporate a PTFE anti-extrusion ring to protect the seal components from dynamic impulse damage • ¼” to 1” valve seals are crimped in place to maintain integrity during excessive flow conditions and

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Interchangeable with Snap-Tite 71-Series Materials: • Machined components are manufactured using solid Steel or 316 stainless bar stock. • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life. • Steel componentry is plated using ROHS Compliant Trivalent Chrome. • Steel coupler sleeves are hardened to resist deformation and maximise service life. • Steel nipples are hardened to provide heavy duty performance. Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F). • All couplers and nipples incorporate PTFE or TPC-ET anti-extrusion rings to protect the seal components from dynamic impulse damage.

Request for a quote

TITAN MACHINERY

United Kingdom

Hydraulic station manufacturing refers to the process of designing, assembling, and producing hydraulic power units or stations. These units are essential components of hydraulic systems used in various industrial applications, including manufacturing, construction, agriculture, and more. Hydraulic stations provide the necessary power and pressure to drive hydraulic machinery, such as cylinders, motors, and valves. The manufacturing process of hydraulic stations involves several key steps: Design and Engineering: The process begins with the design and engineering of the hydraulic station. This includes specifying the required flow rate, pressure, and functionality based on the application's needs. Engineers create detailed schematics and plans for the hydraulic station. Component Selection: Manufacturers carefully select hydraulic components such as pumps, motors, reservoirs, valves, filters, and hoses based on the system's specifications. The chosen components should be durable.

Request for a quote

COLLETT & SONS LTD

United Kingdom

> Click on the "WEBSITE" link for more > Our dedicated Team of Jacking & Skidding Engineers have the knowledge and expertise required for machinery extraction and the relocation of industrial cargoes in confined and restricted environments. Utilising our specialist jacking & skidding equipment our Heavy Lift Team can ensure that no matter what the environment we can safely and securely undertake the heavy transport, extraction and load positioning of machinery & industrial cargoes. In restricted environments crane hire is not always a suitable option. Utilising our specialist hydraulic jacking & skidding systems Collett Engineers have the ideal solution for these confined spaces, providing a lifting, extraction and load positioning service in areas where traditional transport arrangements may not be a suitable option.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

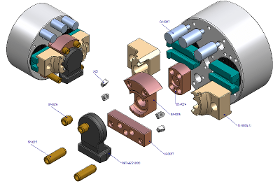

Repetition Accuracy of 5 micron Extremely High Clamp Forces Low wear due to Nitrogen Hardened Surfaces Suitable for Internal or External Clamping BEST hydraulic centric vices are a no compromise solution to repeating and long running 4th and 5th axis workholding. BEST have focused on the production of high accuracy, high rigidity vices. These vices are suitable for both internal and external clamping. They offer very high clamping forces and repeatability of 0.005mm and a centring accuracy of 0.01mm. The Hydraulic vices also have the following options: Clamp Path Monitoring, Fixed Jaw, Central Lubrication System and Positive Air Pressure to prevent swarf ingress.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compact 5th axis design Quick Indexing 5th axis Zero Backlash A tilting typ rotary table with compact design and high accuracy, suitable for 4th and 5th axis machining. The RKT series allows for 5th axis machining on standard 3 axis machines either through intergration with the machine control or with an external control. 5th axis prepared machines require for machine control intergration. AV specification comes with an external controller that functions off a spare M-Code; used for machines that do not have 5-axis preperation.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick and reliable workholding is essential and 1st MTA not only offers a vast range of standard equipment but also provides customised workholding solutions to suit individual application requirements. Such bespoke equipment can solve complex production problems or, in standard applications, substantially reduce set-up and idle times. 1st MTA’s aim is to provide: Extra Versatility Fewer Clampings Higher Efficiency, Accuracy and Repeatability These tailored solutions, wherever possible, will be based on components from the extensive standard range; by using this modular approach there are significant cost and time advantages to be gained and in the majority of cases successfully solutions are devised to problem components on this basis. However, MTA is just as happy to go back to basics and produce totally bespoke “one-off” items to meet customers requirements. Whichever method is used it will be securely based in the company’s wealth

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Greatly expand the capability of your EDM machine Stainless steel construction Sealed and fully submersible Light weight and compact The DM series of rotary tables are completely waterproof and are designed for EDM applications. They are built from stainless steel and can be completely submerged. The DME100 table has an a Fanuc absolute encoder to improve precision and is only available as a 4th axis. The DM100 is available with a Kitagawa controller or with a suitable motor to interface with a machine that has already been prepared for an additional rotary axis. Both rotary tables are compact and high precision and will greatly expand the capability of a spark or wire erosion machine. These rotary tables are available with specially designed submersible chucks and tailstocks. RAV specification comes with an external controller that functions off a spare M-Code; used for machines that do not have 4th axis preperation.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Ultra Compact Rotary Table No table face for direct connection to trunnion setups High speed and accuracy Rotary joint as an option *R Kitagawa CK series is a Ultra compact body for small footprint machines, trunnions can be directly mounted to table spindle keeping overall setups very compact. Available with all motor types in right or left hand configurations to suit a variety of machine models. Price includes Rotary Table, Motor to suit (Fanuc, Mitsubishi or Yaskawa) and cables internal and external(subject to machine model). The CKR comes with rotary joint to suit hydraulics or pneumatics. RAV specification comes with an external controller that functions off a spare M-Code; used for machines that do not have 4th axis preperation.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compact Design Triple disc brake system for high clamping force High speed and accuracy Rotary joint as an option MR series Rotary Table with compact design and high accuracy. The innovative triple disc brake system gives substantially increased clamping force. Available with all motor types in right or left hand configurations to suit a variety of machine models. Price for tables numbered MR*** includes Rotary Table, Motor to suit (Fanuc, Mitsubishi or Yaskawa) and cables (internal and external). RAV specification comes with an external controller that functions off a spare M-Code; used for machines that do not have 4th axis preperation. **Drawings and models subject to machined control**

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Built-in check valve and sensor switch The Y-RE cylinder series is Kitagawa's standard close centre cylinder with built-in proximity swithcs along with built-in check and pressure relief valves. The cylinder can be bought as a a single unit or to suit a required machine under request.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compact and lightweight Built in check valve and pressure relief valve Built in sensor switches Optional through coolant or air Closed centre cylinder with compact design and built in Rotary Joint for through air or coolant capacity. Features include built-in check and pressure relief valve along with stroke sensor switches as well as rotary joint.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compact short body design Increased max operating speed Increased pull force gives larger chuck range Kitagawa hydrualic cylinders are made with high grade alloy steel. The SS series cylinders are compact design to fit on size critical machines while giving a larger pull force to allow for operation of a wide range of chucks. The cylinder can be bought as a single unit or to suit a required machine under request.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Kitagawa's SR series is a open centre hydraulic cylinder to match Kitagawa's B200 and BB200 range.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Longer piston stroke Large Through Hole Increased max operation speed Kitagawa hydrualic cylinders are made with high grade alloy steel. The S-L series cylinders are Kitagawa's long stroke option for standard range of hydrulic cylinder these cylinder give more options when standard stroke lenghts will not provide full oparation. The cylinder can be bought as a single unit or to suit a required machine under request.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High pull and push force to operate range of chucks Light wieght and compact design Large Through Hole Kitagawa hydrualic cylinders are made with high grade alloy steel. The S series cylinders are Kitagawa's standard range of hydrulic cylinder and are fitted as standard to a wide range of machines. The cylinder can be bought as a single unit or to suit a required machine under request.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

For over half a century, Kitagawa products have inspired confidence in customers all over the world. The Kitagawa series of chucks is wide-ranging and so technologically advanced that we can offer solutions for all machining conditions, no matter how punishing. Manufacturing systems with exceptional quality controls ensure the production of highly precise and superior products, which guarantee trouble-free operation. Our unique innovations in workholding solutions, supported by highly specialised design teams and a proven history of excellence, shows our capacity to challenge the world of engineering.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Precision Hydraulic Coupler, 10” Steel Tube and Snap-On Adaptor (Handy to put an instant extra length to the grease line).

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Hydraulic Grease Nipples. Case hardened, zinc plated and passivated for resistance to corrosion.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Hydraulic Grease Nipples. Case hardened, zinc plated and passivated for resistance to corrosion. Hydraulic - 90° Angle Type

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Hydraulic Grease Nipples. Case hardened, zinc plated and passivated for resistance to corrosion.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Case hardened, zinc plated and passivated for resistance to corrosion

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Aging-resistant hydraulic oils based on mineral oils, with superior corrosion and wear protection even under extreme loads.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Biodegradable gear and hydraulic oils based on synthetic ester oils, with good low-temperature behaviour and low coefficient of friction thereby reducing energy consumption.

Request for a quote

WRIGHTS RECYCLING MACHINERY LTD

United Kingdom

The KN hydraulic demolition shears have a 360 degrees rotation, making effective work for demolition, scrap metal, general waste, ferrous and non-ferrous companies. Reducing waste in the quickest and most cost effective way. The KN demolition shears are one of the best quality built shears on the market today with faultless welding and high quality materials used building the shears, it takes a lot of operator malfunction to damage to shears.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Hydraulic power units are produced in close cooperation with customers. Highly-qualified technical and commercial marketing staff are continually working to meet the needs and wishes of our customers and their problems from the field of hydraulics. Gidrolast offers our customers knowledge, expertise and experience in solving such problems. Gidrolast engineering knowledge is a core competence of projecting processes. In this process, our engineers design hydraulic power units to customer requirements, all necessary documentation is prepared and risks and production capabilities are assessed and the whole project is prepared for execution. In the sales process, the customer gets a full quotation. The whole process of monitoring the execution of customer’s order is carried out by the business information power unit. In order to delivery process the hydraulic power unit is produced, tested, adjusted and prepared for transport on the basis of technical documentation.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Gidrolast specialises in the design and manufacture of both Single Acting and Double Acting Telescopic Hydraulic Cylinders. We build both standard catalogue telescopic designs as well as custom application engineered telescopic cylinders. Often a hydraulic cylinder is required to fit into a very tight space and yet provide a stroke that is actually longer than its fully retracted length. A standard rod cylinder cannot do this. A telescopic cylinder, however, can achieve a very long stroke from a compact retracted length. Telescopic cylinders use a series of nested tubular segments sliding within one another (see diagram below). This enables them to provide a very long output stroke from a very short retracted length in one combined actuator. These cylinders are available in 2, 3, 4, 5, or even 6 stages. Most telescoping cylinders are single acting. That means that they extend using hydraulic pressure but then retract using gravity and the mass of the load.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Metallurgical equipment all endure heavy-duty service under very demanding environmental conditions. Equipment is subjected to moisture, dirt, saw dust, wood chips, sap and tar and slamming loads. The hydraulic cylinders used on that equipment must meet these challenges day after day. Gidrolast has over 15 decades of experience building hydraulic cylinders for this tough industry. In fact, you could say we cut our teeth in the forestry industry. For our customers, that experience is invaluable. Gidrolast designs cylinders that are able to endure the difficult conditions that metallurgical machinery encounters on a daily basis.

Request for a quoteResults for

Hydraulics - Import exportNumber of results

49 ProductsCountries

Company type

Category

- Cylinders, hydraulic (10)

- Hydraulic equipment (7)

- Pumps, hydraulic (7)

- Assemblies, hydraulic (7)

- Hydraulics systems (5)

- Greasing equipment (5)

- Pumps (3)

- Fittings, pipe, tube and hose - plastic (2)

- Cylinders, pneumatic (2)

- Valves, hydraulic (1)

- Hydraulic tools (1)

- Lubricants, industrial (1)

- Hydraulic brakes (1)

- Hydraulic springs (1)

- Machine tools - metal machining (1)

- Shock absorbers, vehicle (1)

- Oils, industrial (1)

- Demolition - machinery and equipment (1)