- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mills

Results for

Mills - Import export

HENAN RICHI MACHINERY

United States

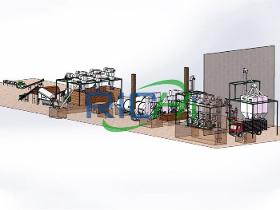

Wood pellet mill is special pelletizer system for the production of wood pellets, which are suitable for wood pellet plants, sawdust mills, furniture factories, power plants and other fields. As a wood pellet mill manufacturer for more than 25 years, we professionally provide users with various series of wood waste pelletizing machine and wood pellet plant for selection.

Request for a quote

HENAN RICHI MACHINERY

United States

Sawdust pellet mill is mainly composed of feeding system, pelletizing system, transmission system and overload protection system. After the machine is turned on, first put into the feeder according to the production demand, the material enters into the pelletizing chamber for pelletizing through the feeder, and is converted into wood pellets and extruded out of the die holes under the extrusion of the ring die and the pressure roller. The produced wood pellets have smooth surface, high density and high hardness, which can be mainly used for civil heating and living energy.

Request for a quote

HENAN RICHI MACHINERY

United States

RICHI is mainly engaged in the research and development, manufacturing of biomass pellet mills,also specializes in biomass pellet mill for sale. Our biomass pellet mill can be used to process all kinds of agricultural and forestry waste pellets (wood, straw, hay, grass, rice husk, efb bamboo, bagasse, peanut shell…). RICHI biomass pellet mill is designed with high quality, environmental protection and intensification. It can produce bio pellets that meet the high quality pellets standard of different countries, ideal for biomass pellet manufacturers.

Request for a quote

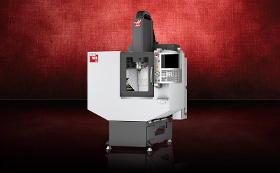

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Compact Mill; 12" x 10" x 12" (305 x 254 x 305 mm), ISO 20 taper, 5 hp (3.7 kW) vector drive, 30,000 rpm, 20-station automatic tool changer, coolant pump, high-speed machining, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor, and USB port CM-1 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

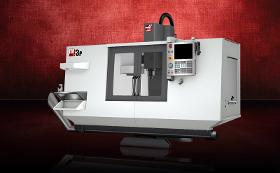

Toolroom Mill with Tool Changer; 40" x 20" x 16" (1016 x 508 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, full enclosure, 10-station automatic tool changer, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-3P Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Toolroom Mill; 40" x 20" x 16" (1016 x 508 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 4000 rpm, full enclosure, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-3 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Toolroom Mill with Tool Changer; 40" x 16" x 16" (1016 x 406 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, full enclosure, 10-station automatic tool changer, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-2P Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

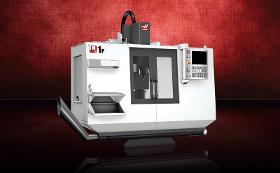

Toolroom Mill; 40" x 16" x 16" (1016 x 406 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 4000 rpm, full enclosure, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-2 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Toolroom Mill with Tool Changer; 30" x 12" x 16" (762 x 305 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, full enclosure, 10-station automatic tool changer, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-1P Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

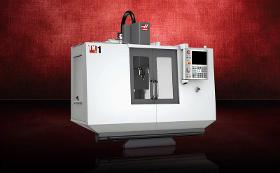

Toolroom Mill; 30" x 12" x 16" (762 x 305 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 4000 rpm, full enclosure, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-1 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center for Education; 16" x 12" x 10" (406 x 305 x 254 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 4000 rpm, 300 ipm rapids, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor, and USB port. Does not include a tool changer or coolant pump. Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 16" x 12" x 10" (406 x 305 x 254 mm), 40 taper, 15 hp (11.2 kW) vector drive, 10,000 rpm, 1200 ipm (30.5 m/min) rapids, high-speed 10-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, and rigid tapping. Three-phase power only. SMINIMILL Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 20" x 16" x 14" (508 x 406 x 356 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, 20-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, 15" color LCD monitor, memory lock keyswitch, USB port and work light. MINIMILL2 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 16" x 12" x 10" (406 x 305 x 254 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, 10-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port. MINIMILL Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

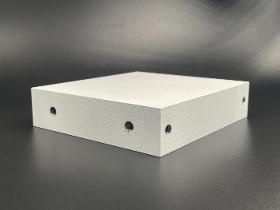

UP RAPID PROTOTYPING CO.,LTD

United States

Up Rapid is a Chinese factory mainly engaged in 3-axis and 5-axis CNC machining. We mainly process metal and plastic materials. While processing batch parts, we also make product prototypes. We are familiar with various surface treatment processes and can provide Consumer goods, electronics, telecommunications equipment, automotive, machinery and other industries manufacture parts and prototypes.

Request for a quote

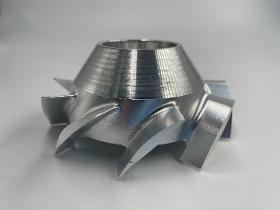

UP RAPID PROTOTYPING CO.,LTD

United States

Up Rapid is a Chinese factory mainly engaged in 3-axis and 5-axis CNC machining. We mainly process metal and plastic materials. While processing batch parts, we also make product prototypes. We are familiar with various surface treatment processes and can provide Consumer goods, electronics, telecommunications equipment, automotive, machinery and other industries manufacture parts and prototypes. This product is a mechanical equipment turbine, and we use CNC machining to shape it according to the drawings provided by the customer. Such complex mechanical parts require 3+2 axis or five axis CNC to process.

Request for a quote

UP RAPID PROTOTYPING CO.,LTD

United States

Up Rapid is a Chinese factory mainly engaged in 3-axis and 5-axis CNC machining. We mainly process metal and plastic materials. While processing batch parts, we also make product prototypes. We are familiar with various surface treatment processes and can provide Consumer goods, electronics, telecommunications equipment, automotive, machinery and other industries manufacture parts and prototypes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMERICULE, INC.

United States

Build up or “blinding” on vibrating screens is a maintenance headache, causing downtime and loss of productivity. Screen cleaning balls are vital to the effectiveness of the sifting/grading process in many industries. Americule’s POLYBALL™, the leading manufacturer in the world for screen cleaning sifter balls, incorporates advanced molding technology that provides advantages of high-performance polyurethane at competitive prices and may be ordered in a variety of sizes, colors and even with a solid magnetic steel core. The physical properties of the premium-grade polyurethane utilized in our Polyball™ offer a phenomenal improvement over rubber balls.

Request for a quote

CHARDON TOOL

United States

Optical quality finish with controlled waviness to 0.1 microns, then precisely set in gage quality tungsten carbide shanks.

Request for a quoteResults for

Mills - Import exportNumber of results

20 ProductsCountries

Company type