- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vertical mixers

Results for

Vertical mixers - Import export

LAVELLA

Turkey

Special watersaving aerator is used in our faucets. (Foam flow, Lime Crusher) It is recommended to use a filter at the entrance of the flat in order to prevent any possible contamination in the installation from damaging the luminaire. All our products are sent in a box with a warranty certificate and invoice. Battery Technical Dimensions Battery spout length 141.80 mm Battery connection threads 3/4 ”1/2” Ideal working pressure 34 Bar Our products are made of 1st quality brass material. 5 years warranty. Water and pressure testing has achieved 100% success in all of our products. Our products are made of healthy materials. Our products are high quality chrome plated.

Request for a quote

KASAG SWISS AG

Switzerland

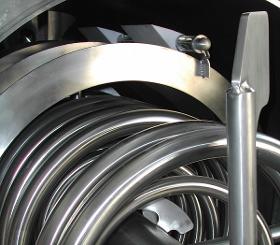

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

SUS304 material prevents steel rust from polluting food and working environment. (Option: SUS316 for food contact surfaces) SUS304 control box includes: mixing speed adjustment, timer, temperature, on/off button, hydraulic emergency stop, lift, lower, tilt and return to position. Food grade scraper blades, double jacketed bowl, leak proof design. Cooking vessel volume: from 100L to 500L. Power: 220V~415V (depends on request) Steam heating

Request for a quote

SAYGINLAR AGRICULTURE MACHINERY LTD.

Turkey

NAME OF THE PRODUCT: FEED MIXER WAGON MODEL OF THE PRODUCT: VERTI-12 TYPE OF AUGER: vertical DISCHARGE TYPE: optional VOLUME(cbm): 12 NUMBER OF AXLE: 2 NUMBER OF AUGERS: 2 HYDRAULIC POWER: Tractor NUMBER OF KNIVES: 16(8x2) OVERALL LENGTH: 5950mm MINIMUM REQUIRED HP : 70 HP OVERALL WIDTH: 2350mm POWER: PTO OVERALL HEIGHT: 2800mm optional BACK LOADER: WEIGHT: 4500kg SIDE OF DISCHARGE: right Sheet metal thickness of the auger 12 mm optional DIGITAL SCALE: PTO DRIVE 540 RPM Time spent to mix for one load 15minutes Sheet metal thickness of the bottom 20 mm Maximum number of Dairy Cows which can be fed with one load 90-100 cattle Sheet metal thickness of the side walls 6 mm

Request for a quote

MIXACO MASCHINENBAU

Germany

The Robust Workhorse: The high-performance MIXACO universal mixer is ideal for many different applications. Whether slow, gentle homogenization or thorough mixing is required, consistently high quality is guaranteed for every mixing process. In particular, the universal mixer’s highly flexible design possibilities enable it to be adapted easily to suit the required mixing task and individual on-site requirements. The MIXACO universal mixer is available in sizes from 20 to 6,000 liters. All Benefits at a Glance •Can be used for a wide variety of applications, such as homogenization, dispersion, coating or granulation •Mixer tools optimized for the individual mixing task •Performance-optimized selection of mixing drives ensures high energy efficiency •Rapid cleaning possible when pivoting mixer lid is open •Double-walled mixing vessel enables ideal temperature control of product during mixing •ATEX version possible

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCANDINAVIAN & UK MACHINES

Sweden

TECHNICAL DETAILS: AGGREGATE STORAGE HOPPERS. 4 hoppers with a total capacity of 14 m³. Dimensions of the set : Length: 2 x 5,900 mm. Width: 2,415 mm. Made of 4 mm steel plate. WATER DOSING. Batching system consisting of a water meter with 1.5'' inlet valve and programmable operation. Pneumatic-valve opening and closing. Water feed system with 1.1 kw pump + pressure control system. Connection with concrete mixer by 1½'' galvanised pipes. 265 litres Water tank. MIXING SET. Mixer with vertical axle FTR-750. Capacity: 750 litres. Useful vibrated concrete capacity: 500 litres per cycle. 22 kw Siemens geared motor. Weighing system fitted with 3 load cells of 2,000 kg. COMPRESSED AIR INSTALLATION. 3 HP compressor with 90 litres tank. Contact us for more details.

Request for a quoteResults for

Vertical mixers - Import exportNumber of results

7 ProductsCompany type