- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vibrating feeders

Results for

Vibrating feeders - Import export

UGUR MAKINA CRUSHING & SCREENING

Turkey

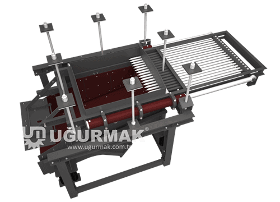

UĞURMAK UMBB Series Vibrating Feeders are positioned in the intermediate stock points, at the exit of the silo or bunker where the material is stocked, in order to ensure continuous feeding of the machines at all stages after the primary crushing stage in crushing and screening processes.

Request for a quote

EC PLAZA

South Korea

The process of Infeed Shaker 1. Conveying 2. Dewatering 3. Grading 4. Sieving Product Features 1. Equipment that hygienically transports food, grain, and medicines using vibration. 2. Once the equipment is installed, stable and semi-permanent transportation is possible. 3. Install a feeder suitable for the customer's on-site conditions. 4. Various types of infeed shaker designs for each sample. 5. Securing equipment safety through analysis and simulation. Our Company DUK YOUNG ENGINEERING Based on powder and liquid mixing technology for the past 30 years, our company provides total engineering service of automation processes required throughout the industry, such as storage, transfer, metering and input.

Request for a quote

TOMECH SOLUTIONS

Romania

Feeders are devices used to regulate and control the flow of bulk materials from a storage container or hopper to downstream processes or equipment. They play a vital role in ensuring a steady and controlled supply of material, enhancing the efficiency and productivity of material handling systems. Vibrating feeders are a type of feeder that utilizes vibrations to move materials along a trough or tube. Vibrating feeders are commonly used in industries such as mining, aggregate processing, and pharmaceuticals due to their ability to handle a wide range of materials and feed rates while minimizing spillage and dust emissions. We specialize in feeder design services, offering tailored solutions to optimize material flow, feed rate, and system performance. Our expertise encompasses the design, selection of feeder type, and integration of feeding equipment into material handling systems to meet the specific requirements of our clients and enhance their operational efficiency.

Request for a quote

RNA AUTOMATION LTD

United Kingdom

RNA and Asyril cooperate in the development and sales of Flexible Part Feeding Systems and Vibration Platforms. Asyril’s award-winning series of Asycube flexible vibrator feeders offers high performance part feeding, pre-orientation and optimal surface distribution of bulk parts and components.

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— No stirring agitator or other rotating parts for ingredient flow without degradation — Vibration amplitude feedback ensuring linear conveyance characteristics over the entire feed rate range Power range 10 - 450 dm³/h 20 - 1000 dm³/h 300 - 3000 dm³/h 650 - 6500 dm³/h

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UGURMAK UMG Series Vibratory Grizzly Feeders are the main feeder type used in crushing and screening plants. They take place for feeding jaw or impact crushers used in primary stage. Offering high performance even in the harshest conditions, UMG Series feeders can be used for any size of material, from oversized material to small size stream materials. Thanks to the adjustable grill distance, the product size that cannot be included in the primary stage can be changed. It has a very solid chassis. Feeder body is seated on it with helical springs in sufficient number and strength. On this feeder body, there is a large volume bunker in the structure offering high strength. It can be used in all mobile and stationary primary units.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

In some crushing and screening processes, there may be a need to divide the process in half. In such cases, tunnel type intermediate stock center is frequently preferred. It is positioned in the middle of the stock center. Their main field of use is to ensure that the stocked material is fed to the second stage of the process. This vibrating feeder type UTF series Tunnel Feeder provides high performance in heavy conditions

Request for a quote

FEMIA INDUSTRIE

France

Pulls off the husks of unprocessed ears of corn.Machine primarily comprised of a roller table, a vibrating feeder and of a variable speed conveyor with its hopper in the upper portion. The roller table is comprised of 4, 8, 12 or 16 “Lanes” keeping in mind that a “Lane” comprises 2 axes with rollers. Range of various husker rollers according to the variety of corn processed Regular feed thanks to a variable speed conveyor belt and a vibrator that aligns the ears before the roller table. Recovery of the husk and silk waste under the roller table.

Request for a quote

ROBINSON CO.

Turkey

The Air Channel is used for cleaning wheat, barley, legumes and soybeans. The machine removes all kinds of light materials different from cereal grains in terms of aerodynamic properties: garbage, straw and spike fractures, various seeds, peeled shell and dust from the product by means of air flow. While the grain products are distributed homogeneously in the width of the Air Channel with the feeding table of the machine or a vibrating feeder, the light particles in it are conveyed to the upper outlet channel with the air flow coming from the bottom, and the cleaned product falls down and transferred into the system. ◾ The lighting created by the window enables the separation to be seen clearly and thus all kinds of air adjustments can be made. ◾ Manufactured in two types, this machine with vibro motor is usually used with a Peeler machine, the non-motorized one is used with a Garbage Purifier machine.

Request for a quote

ROBINSON CO.

Turkey

It performs the task of separating the light grains and shells of the unwanted foreign substances from the grain with the air flow. The grain is spread over the bottom by a vibrating feeder and conveyed towards the air duct. It is washed by the air flow opposite the movement of the grain, which enters the air channel with a homogeneous distribution. In the meantime, unwanted light grains are separated from the grain by moving with the air. Applications Fields ◾ Food Industry ◾ Flour Mills ◾ Semolina Mills ◾ Feed Mills ◾ Grain Cleaning Plants ◾ Corn Processing Plants ◾ Oil Factories ◾ Plywood Factories ◾ Grain Storage Silos ◾ Corn Mills ◾ Corn, barley, rye, oats, and so on grain processing plants

Request for a quote

HOCHRAINER GMBH

Germany

The availability and output of a production system is only as high as the process reliability of its feeding systems allows. Thanks to more than 35 years of experience as a system supplier for assembly technology and custom machines, we can implement a large variety of applications tailored to customers' requirements;

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Unbalance motors can be used as drives for almost each case of application in the vibration feeder technology and over all industries. Unbalanced motors are the prefered drive system, in particular if it depends on high throughput of bulk material. Advantages and benefits available as standard for explosion proofed ATEX zones 21+22 available as standard for CSA-apllication "Class 1 + 2" available as standard with thermistor operationally safe in continuous employment high level of performance with compact dimensions efficiency latest state-of-the-art of technology and production conformity with all EC Guidelines which affect the drives available for 60 Hz power systems and other mains voltages Construction and operation mode The AViTEQ unbalance motor is a three-phase ac induction motor, on which weights are eccentrically attached at the ends of the running shaft; so-called eccentric weights (flyweights). Centrifugal forces are generated with rotating waves. The value of these

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Magnetic vibrators can be used very versatile. The advantages of magnetic vibrators match all designs of vibrating machines. For almost each case of application in the vibration feeder technology and over all industries magnetic vibrators are the favorite system, in particular if it depends on high dosing accuracy. Magnetic vibrators are made in Germany on a highest standard. Advantages and benefits easy and continuously adjustable during running conditions PAL System (protection for wrong amplitudes) available for 25/33/50/100 (30/40/60/120)Hz variants immediate start/stop after switching linear amplitude Reliable permanent use High level of performance with compact dimensions Wear-free, without rotating parts Efficiency (long operating cycles and service life) Newest state-of-the-art of production engineering Conformity with all EC Guidelines, which affect the drives available for explosion-endangered spaces (Ex) available for 60 Hz power systems and other mains voltages Temp

Request for a quote

THOMSON MACHINERY BV

Netherlands

Exciting vibration force and power are well matched, vibration force is large, the weight of the body is light, small volume, low mechanical noise; 2) Stable amplitude; 3) Adjustable& flexible Vibration frequency; 4) Simple structure in linear type ,easy in installation, maintain, and operation; 5) Adopting high quality material parts ,electric parts and operation parts. 6) High performance feeding speed. 7) Various model, can be customized

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

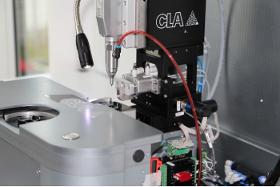

Automatic screwdriver with torque measurement Compact station for workbench to ensure your assemblies screwed with high precision torque control. Main features : - Screws feeder by vibrating bowl - Preparation of the next screw in hidden time - Automatic screwdriver with integrated torque sensor - Preparation of the next part in hidden time thanks to the charging carousel - Removable precision tool to ensures a precise positioning and a multi-types parts management - User friendly interface allowing various screwing positions and configurations dedicated by type of parts - Ready to be integrate in assembly line

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The equipment is widely used in different bulk foods detection, like nuts, seed kernel, peanut, beans, dehydrated fruits and vegetables, tea, Chinese herbal medicine and others. It can identify and remove metal, glass, stone, soil, etc. Especially for nuts, the X ray machine also can remove wormhole grains, empty seeds, shriveled grains, etc. The material into the device and distribute uniformly on the conveyor belt through the vibration feeder, The ray of X-ray generator penetrate materials, then distinguish and extraction according to by image, foreign body discharge to waste tube through the injection valve, finished products turn out from another port.

Request for a quote

WHITE STEEL GMBH

Germany

Flow meter system “ Krohne “ Double conveyor system 8 diving nozzle filling system Caps transferring vertical conveyor Vibrator caps feeder Herma double head labeling system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear system. Filling capping labeling machine .

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

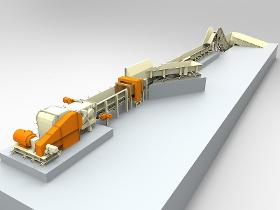

The scrap and short-wood line is designed for processing root pieces, slabs, edgings, panel waste pieces, windfall wood, and of course logs. With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient drum chippers, the production of high-quality chips is guaranteed. Key features Simple feeding of wood directly from the truck Robust underground bins or vibrating feeders Vibrating conveyor lines Drum chipper Metal sensor and roller conveyor cleaning system Advantages Use of almost any type of wood material Continuous and uniform material feed Safe removal and discharging of rocks, sand, and other contaminants High lling level and high utilization of chipper capacity

Request for a quote

RNA AUTOMATION LTD

United Kingdom

Special purpose machinery, automation systems, semi or fully automated production lines, sorting and assembly turnkey solutions Rotary & CAM Indexing Systems Rotary indexing table, High performance conveyor, Palletised conveyor, Linear track systems Robotic Systems 6/7 Axis, Scara, Cartesian, Collaborative; robot programming and integration, robotics and handling, Welding, high speed pick & place, vision guided robotic system Inspection & Vision Systems Sensing, Inspection, Guidance, Quality Control, Sorting Feeding & Handling Bowl & Linear Feeders, Centrifugal Feeders, 3-Axis Vibration Feeders, Rotary Indexing Tables, Pick and Place Systems, Step Feeders, Carpet Feeders

Request for a quote

OFFICINE CONTERNO SRL

Italy

Studied for the extraction and dosage of bulk materials of various sizes. The adjustable intensity, unidirectional vibration is generated by eccentric mass electric moto-vibrators. Made of suitably bent and stiffened sheet metal, they are used in various sectors, from the steel to the mining industry.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Officine Conterno designs and manufactures crushing, screening and aggregate washing plants for the production of concrete, bituminous conglomerates, road foundations or railway ballast. Jaw crushers, primary, secondary and tertiary mills, feeders, rotating screens, vibrating screens, vane or barrel scrubbers, and cyclonic separation groups ... These are just some of the machines in our product range.

Request for a quote

OPT MAKINE

Turkey

Mobile Solutions PORTABLE CRUSHING AND SCREENING UNITS Mobile units are right solutions when temporary aggregate production is required for short-term projects, like road and dam construction. As most of the time the equipment is moved out of the temporary quarry, disassembly, transportation and installation expenses add extra costs that can be just as significant as the start-up investment itself. In such cases, despite higher initial investment costs, mobile crushing and screening solutions are better options than stationary ones because of the time-saving disassembly, transportation and installation advantages they provide. Advantages: -Compact, -Easy to setup, -Less space required, than stationary units. Mobile jaw crusher Mobile vibrating grizzly feeder Mobile impact crusher

Request for a quote

HAVER NIAGARA GMBH

Germany

Conveying technology has a top priority at HAVER NIAGARA. Our vibrating feeders can be used in all the industrial fields where HAVER & BOECKER is active. Not only vibrating feeders can be used, but also bunker discharge chutes. Uniform vibration assures an expeditious conveying speed while being gentle on the product. Depending on the requirements of our customers, we offer feeders with magnetic/eccentric drives or exciters. The same is true for the design shapes. Depending on the requirements, we have a variety of possibilities to design the feeder. The open, partially encapsulated, and completely encapsulated designs all belong to our product range, as do the multiple channel tube vibrating feeders. Thus we are optimally set up to successfully support our customers in everything having to do with their process chains. You’ll find detailed information in our product brochures and specification sheets.

Request for a quoteResults for

Vibrating feeders - Import exportNumber of results

24 ProductsCountries

Company type

Category

- Automation - systems and equipment (3)

- Crushing and grinding machinery (3)

- Flour milling - machinery and equipment (2)

- Building materials, manufacture - machinery and equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Conveyor systems (1)

- Engineering - industrial consultants (1)

- Feed distribution systems (1)

- Food canning and preserving - machinery and equipment (1)

- Food industry - machinery and equipment (1)

- Paper - Printing - Machines & Equipment (1)

- Weighing and dosing equipment (1)

- Wood veneer - machinery and equipment (1)