- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water purification - systems and equipment

Results for

Water purification - systems and equipment - Import export

FLOTTWEG SE

Germany

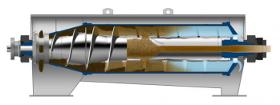

The demands on the quality and efficiency of sewage treatment plants are growing from year to year, not least due to rising energy and disposal costs. As a result, using decanters to dewater sludge means using state-of-the-art technology. The C-series decanters from Flottweg achieve high performance with reduced energy consumption. Flottweg Wastewater Decanters offer advantages over other processes and competitors' machines: ► High dry solids values in the discharged material ► Higher power density within a small footprint ► Powerful Flottweg Simp Drive® drive ► Reduction of operating costs due to reduced need for flocculant ► Additional energy recovery with the Flottweg Recuvane® system ► Economical bowl and scroll drive ► duces the energy consumption of your decanter by 10 to 30 percent

Request for a quote

BURRE HYDRAULIK GMBH

Germany

Application: watergate technology

Request for a quote

BURRE HYDRAULIK GMBH

Germany

Application: Ro-Ro Landing Systems

Request for a quote

BURRE HYDRAULIK GMBH

Germany

Piston rod with ceramic coating With integrated position measuring system Application: floodgate and bridge lifting technology

Request for a quote

FLOTTWEG SE

Germany

In the process of treating waste water, fine biological sludge is constantly produced during the decomposition process at a sewage treatment plant. For a stable decomposition process in the biological treatment phase, the sludge produced in the secondary sedimentation pond, also known as excess sludge, is removed and fed into the digestion tower. Flottweg's OSE decanters thicken the sludge before it enters the digestion tower. Sewage treatment plants benefit from an even feeding of the digestion tower and can thus optimally use the volume of the digestion tower. The Flottweg OSE decanter is specially designed for sludge thickening. ► Highest gas yield through constant feeding of the digestion tower ► Best possible thickening even with changing feed conditions ► Larger sedimentation volume (due to deep pond and steep cone) enables highest power density (10 - 20 percent) with minimum space requirement

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

A more economic solution for an environmentally sound condensate management is the decentralised oil-water separation directly at the source. Condensate which was processed with ÖWAMAT can be directly introduced as cleaned water into the sewerage system. The devices have a national technical approval and do not require a permit according to the law on water. In addition, the ÖWAMAT oil-water separators do not create any energy costs, boast enormous filter service lives and can be retrofitted into older systems without difficulty.

Request for a quote

ATMOSFER MACHINERY

Turkey

Our RO system offers a versatile production capacity from 250 to 4,000 liters per hour. It features a stainless steel high-pressure pump and a user-friendly 7" touch screen PLC interface. To ensure precision and efficiency, a digital flow meter measures production and wastewater quantities, and flow rates can be adjusted with a stainless needle valve. Pressure sensors on the touch screen monitor network and membrane input pressure, automatically stopping the system and displaying errors if preset pressure values are exceeded. Users can monitor the Total Dissolved Solids (TDS) value on the touch screen. The system includes three high-quality solenoid valves controlled by the PLC microprocessor for precise management. The electric panel ensures safety and longevity with Motor Protection and phase Protection functions. The system is housed in a visually appealing stainless cabinet.

Request for a quote

ATMOSFER MACHINERY

Turkey

Reverse Osmosis (RO) systems are renowned for their exceptional water purification capabilities, effectively reducing up to 99% of contaminants. The RO series we specialize in is tailored to meet the demanding needs of industrial water treatment across various sources, including brackish, surface, and municipal water supplies. These industrial reverse osmosis water treatment systems are engineered with upgraded materials and high-capacity technology, making them well-suited for applications in diverse industries. Notably, these systems are uniquely designed and manufactured in the United States, emphasizing energy efficiency and eco-friendliness while consistently delivering high-quality water.

Request for a quote

BUSS-SMS-CANZLER GMBH

Germany

SMS offers sludge drying systems with horizontal thin film dryers for treatment of sludge from municipal as well as from industrial waste water treatment plants. Variations of this sludge treatment process are: Pre-drying up to 35 to 50 % dry solid content before incineration in fluidized bed incinerators 65 to 75 % dry solid content before combined incineration with garbage, composting or landfill Full drying up to 85 to 95 % before thermal utilization as bio-fuel for cement kilns, coal fired power stations, pyrolysis, gasification or other conversion processes before composting and agricultural usage as fertilizer and for soil reclamation In all these drying processes the thin film dryer is the first choice.

Request for a quote

BUSS-SMS-CANZLER GMBH

Germany

The wet product fed through the inlet nozzle is picked up by the rotor blades, applied on the hot wall and simultaneously conveyed towards the outlet nozzle at the opposite end of the body. The generated vapours are streaming counter-currently to the product flow and are leaving the dryer close to the feed nozzle. Evaporating and conveying capacity are adapted by the right rotor blade arrangement. Entrained particles from the dry zone are removed in the wet zone. Moisture levels of less than 1 % can be achieved. The residence time of the product is typically between 5 and 15 minutes. The outstanding heat transfer rate for hot solid products enables cooling of large amounts of solids in a compact machine compared to usually used cooling screws and without cooling air.In product melting like the melting of urea, the particles are heated up and molten inside the dryer. The melt can be mixed with other liquid and solid additives to improve the properties of the final products.

Request for a quote

OKAY ENERGY EQUIPMENT CO., LTD.

China

the water systems's water output 10L/h,20L/h,40L/h,60L/h are available. Features: 1.two way online water quality sensor,RO water, deionized water, or ultrapure water respectively. 2.Cartridges replacing alarm function, based on time and water quality, show cartridges´ used and residual life. 3.Multiple alarm function: no feed water, full water, water quality´s standard exceeding, and cartridge life ending. 4.top polishing resin, ensure ultrapure water´s quality up to 18.2 MΩ.cm, with the lowest TOC level. 5.integrated design of the whole machine, small occupancy, simple appearance, easy to use and safe. Lab Type 1 ultrapure water can be widely used for Flow cytometry, pyrogen sensitive applications, cell and tissue culture, and sentitive analytical work such as HPLC,ICP-MS,GC-MS. TheType 3 RO pure water is for filling water baths and incubators,feeding glassware washing machines and autoclaves.

Request for a quote

KUIDYCH HEATING TECHNOLOGIES (KHT)

Ukraine

Introducing the Mobile Pipe Decoiler PD-200, your solution for efficient coil uncoiling tasks. With its rapid folding and unfolding feature, this equipment optimizes workflow for a variety of applications. Capable of handling coils weighing up to 80 kg, with a maximum height of 600 mm and an external diameter of up to 900 mm, it offers versatility for different coil sizes. Its internal diameter range from 200 mm ensures compatibility with various pipe dimensions. Experience seamless coil uncoiling with the Mobile Pipe Decoiler PD-200, designed for maximum productivity and user convenience.

Request for a quote

HISPANO VEMA

Spain

HYDROS sets a new standard on Sustainable Mobile Watermakers for Rapid Deployment. Thanks to its compact size, light weight, Plug&Play, energy supply alternatives and purification capacity (up to 1.000 liters per hour), HYDROS provides an ultimate solution for increasing demand of Onsite water purification in scenarios fo Natural Disasters, Emergencies, Field Operations or any situation where a high and unexpected water supply is required.

Request for a quote

KEMISAN KLOR-ALKALI A.Ş.

Turkey

LX Series is an industrial-level HypoX Sodium Hypochlorite Generator line with a wide capacity range that answers all industrial water disinfection requirements. LX Series is generally used for large-scale water disinfection requirements of municipality drinking water treatment facilities, swimming pools and aqua parks, large-sized industrial process water disinfection, and cooling tower. With its own chemical synergy of Fresh and Mix Oxidants besides hypochlorite, HypoX® LX Series guarantees to solve important problems like Biofilm, Odor, Legionella, and Strong Pathogens. The high disinfection performance of HypoX® LX Series makes it an effective, economic, green, and safe alternative mainly to chlorine and other biocides in chlorination requirements Applications Areas - Large scaled drinking water&wastewater treatment plants - Swimming pools and aquaparks - Industrial process water treatment - Cooling towers - Reverse Osmoses Process water

Request for a quote

KEMISAN KLOR-ALKALI A.Ş.

Turkey

*MX Series Supplies 400 to 1200gr FAC per hour as Oxidant rich Sodium Hypochlorite With its unique pre-assembled skid, plug&play concept design, HypoX® MX Series brings the advanced electrochlorination opportunity for the need of smart and sensitive disinfection requirements in mid-rate yet in industrial level oxidizing agent production. *By using only Salt, Water and Electricity, produce your own sodium hypochlorite! * Advanced Oxidation with Residual Effect Experience the benefits of Oxidants with the advantages of Chlorine, and forget the disadvantages; Mix Oxidant solution will be offering the benefits like; - Removing all pathogens - Oxidizing Iron, Manganese, and Arsenic better than chlorine - Lowering Disinfection By-Products (TTHM & HAA) - Removing Biofilm on the lines - Enabling chlorine ions to reach 2.5 times further - Eliminating chlorine taste and odor

Request for a quote

PURION GMBH

Germany

The integrated plant PURION PooL 40 PVC-U consists of a filtration of sediments and UV based disinfection of pool water. It is applied to disinfect circulation water of pools. The pre filter removes sediment from the pool water. The following UV based disinfection prevents biological activities – especially forming of algae. advantages: plug and play system for immediate operation up to 95% reduction of chemicals compared to chemical treatment of the water considerable cost cutting due to less cost for chemicals suitable for salt water application low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PURION GMBH

Germany

The UV-plant PURION 2500 DUAL 90 W PRO is made from electropolished stainless steel 1.4571. The PURION 2500 DUAL 90 W PRO is applied to disinfect industrial water and emulsions up to a flow rate of 5 m³/h with a transmission (or turbidity) of the fluids of 20 - 90% per T1 cm. Several options for monitoring of the disinfection performance are available: I DUAL Basic II DUAL OTC III DUAL OTC Professional For optimal installation, we recommend using the PURION assembly system DUAL 1. advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

Die PURION PRO Mehrstrahler-Anlage 2500 / 8 ist zur UV-Desinfektion für größere Durchsätze bei Spezialflüssigkeiten mit sehr geringer Transmission ausgelegt. Der Steuerungsschrank kann mit Lebensdauerüberwachung (OTC 2) ausgestattet werden. Der potentialfreie Kontakt D1-D2 (Fehlersummensignal) ermöglicht die einfache Integration in bestehende Überwachungskonzepte. options for configuration: hot water up to 90 °C Operating Time Counter OTC 2 advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The PURION MULTIPLANT 2501 / 8 is designed to enable UV based disinfection for high flow rates up to 120 m³/h. The electric control cabinet can be equipped with the Operating Time Counter (OTC 2) or Operating Power Detection (OPD 2) via sensor. The potential free contact D1-D2 (error sum signal) enables easy integration into existing monitoring systems. options for configuration: hot water up to 90 °C Operating Time Counter OTC 2 Operating Power Detection OPD 2 advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The UV plant PURION 2001 DUAL PVC-U is applied to disinfect saltwater or other aggressive fluids up to a flow rate of 10 m³/h and a transmission (or turbidity) of the water of at least 90% per T1 cm. Several options for monitoring of the disinfection performance are available: I DUAL Basic II DUAL OTC III DUAL OTC Professional For optimal installation, we recommend using the PURION assembly system DUAL 2. advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

This UV plant PURION 2500 36 W is made from PVC-U. The PURION 2500 36 W PVC-U is applied within maritime environment up to a flow rate of 2.500 l/h and a transmission (or turbidity) of the water of at least 90% per T1 cm. The advantage of PVC-U consists of the resistance against UVC light, salt water and acid fluids. advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The UV plant PURION 2.501 DUAL PVC-U is applied to disinfect saltwater or other aggressive fluids up to a flow rate of 20 m³/h and a transmission (or turbidity) of the water of at least 90% per T1 cm. Several options for monitoring of the disinfection performance are available: I DUAL Basic II DUAL OTC III DUAL OTC Professional For optimal installation, we recommend using the PURION assembly system DUAL 2. advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The UV plant PURION 2.500 DUAL 90 W PVC-U is applied to disinfect saltwater or other aggressive fluids up to a flow rate of 8 m³/h and a transmission (or turbidity) of the water of at least 90% per T1 cm. Several options for monitoring of the disinfection performance are available: I DUAL Basic II DUAL OTC III DUAL OTC Professional For optimal installation, we recommend using the PURION assembly system DUAL 1. advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The UV plant PURION 2.500 DUAL 36 W PVC-U is applied to disinfect saltwater or other aggressive fluids up to a flow rate of 5 m³/h and a transmission (or turbidity) of the water of at least 90% per T1 cm. The PURION 2.500 DUAL 36 W PVC-U operates very efficiently with two PURION UV-lamps 36 W. Several options for power supply and monitoring of the disinfection performance are available. I DUAL Basic II DUAL OTC III DUAL OTC Professional For optimal installation, we recommend using the PURION assembly system DUAL 1. advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The UV-plant PURION 2500 90 W PRO is made from electropolished stainless steel 1.4571. The PURION 2500 90 W PRO is applied to disinfect industrial water and emulsions up to a flow rate of 2,5 m³/h with a transmission (or turbidity) of the fluids of 20 - 90% per T1 cm. The PURION 2500 90 W PRO can equipped with an Operating Time Counter (OTC) to monitor the UV lamps service live. A permanent flow should be ensured during operation of the UV-plant. advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The UV-plant PURION 2500 90 W is made from electropolished stainless steel 1.4571. The PURION 2500 90 W is applied to disinfect drinking water up to a flow rate of 4.000 l/h and a transmission (or turbidity) of the water of at least 90% per T1 cm. The UV-plant PURION 2500 90 W can be applied for drinking water supply of 1-2 households. A permanent flow of water should be ensured during operation of the UV-plant. advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The UV-plant PURION 1000 H is made from electropolished stainless steel 1.4571. The PURION 1000 H is applied to disinfect drinking water up to a flow rate of 1.500 l/h and a transmission (or turbidity) of the water of at least 90% per T1 cm. The UV-plant PURION 1000 H has been developed for temperatures above 40 C°. The used PURION UV-lamp 42 W operates with a special Amalgam technology. Several options for monitoring of the disinfection performance are available. advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The UV-plant PURION 2501 is made from electropolished stainless steel 1.4571. The PURION 2501 is applied to disinfect drinking water up to a flow rate of 10.000 l/h. and a transmission (or turbidity) of the water of at least 90% per T1 cm. It is also used for disinfection of circulation water e.g. from pools or fish ponds up to a dimension of 80.000 l (20 hours operation per day). advantages: additional chemicals are not required for disinfection not affecting smell or taste low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quoteResults for

Water purification - systems and equipment - Import exportNumber of results

62 ProductsCompany type

Category