- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welded pipes

Results for

Welded pipes - Import export

BASE GROUP SP Z O.O.

Poland

We manufacture constructions for energy in accordance with ISO 3834-2 and other certificates. The quality of our welded pipes is certified by the positive audit assessments. Certification body have qualified us as the supplier of the company which is the leader in the global energy market. We produce wide range of steel pipes for equipment of electric power production and transmission.

Request for a quote

COLORICIO.SRL

Romania

We supply round, square, hexagonal and flat barsteel in a broad range of dimensions and steel qualities, includes seamless and welded pipes and tubes according to EN, ASTM and API standards, in a wide variety of steel qualities. They are selected by construction, production and industrial companies due to their durability and multi-purpose use. Our extensive offer allows you to select the most optimal variant for your needs

Request for a quote

COLORICIO.SRL

Romania

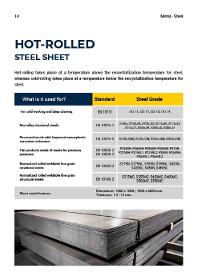

Coloricio offers a wide range of flat and rolled products that prevents steel rust and corrosion through excellent surface finish related to zinc coating: cold-rolled steel/aluminum hot rolled (pickled and oiled) steel/aluminum hot dip galvanized steel/aluminum

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

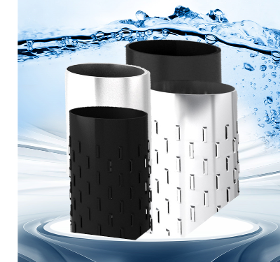

The water and gas pipe (DU) is produced from hot rolled sheet metal and is necessary for the installation of water and natural gas supply pipelines for residential and non residential buildings. Due to its low cost, the pipe is in demand in everyday life, mechanical engineering and at construction sites; metal products and steel structures , machine parts and other popular materials are produced from it . The vgp pipe is easy to install, its service life is from twenty to fifty years or more (time tested). In comparison with plastic counterparts, it is an excellent heat dissipating product and is more resistant to high temperatures and loads. Pipe DN GOST 3262 75 standard sizes from 15 to 50, wall 2.5 4 mm, length 6 lm. Longitudinal electric welded pipe is necessary for the production and construction of structural products. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

The water and gas pipe (DU) is produced from hot rolled sheet metal and is necessary for the installation of water and natural gas supply pipelines for residential and non residential buildings. Due to its low cost, the pipe is in demand in everyday life, mechanical engineering and at construction sites; metal products and steel structures , machine parts and other popular materials are produced from it . The vgp pipe is easy to install, its service life is from twenty to fifty years or more (time tested). In comparison with plastic counterparts, it is an excellent heat dissipating product and is more resistant to high temperatures and loads. Pipe DN GOST 3262 75 standard sizes from 15 to 50, wall 2.5 4 mm, length 6 lm. Longitudinal electric welded pipe is necessary for the production and construction of structural products, while the dimensional grid of longitudinal welded pipes differs in a larger direction from DU pipes F external 10 2000 mm; Wall up to 40 mm;

Request for a quote

METAL IN LTD

Bulgaria

Metal In put into operation a machine for laser cutting of pipes with automatic loading and unloading. The size of the treated pipes is: Round pipes: 120 mm Rectangular tubes: 100x100mm The maximum length of the workplace is 6500mm. The machine is equipped with excellent software that allows different shapes in tubes for subsequent assembly and welding. Also, pipes can be cut so that one wall remains uncut, allowing it to bend easily and accurately and find a frame.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is a welded pipe made of stainless steel,mainly used for connect both of the two sides od the products.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flanges are a crucial component in various piping systems, providing ease of assembly and strength in connecting pipes, valves, pumps, and other equipment. They serve as a plate for covering or closing the end of a pipe and are commonly used in plumbing, oil and gas, petrochemical, and food industries due to their durability and corrosion resistance. Types and Specifications Stainless steel flanges come in several types to suit different applications: Weld Neck Flanges: Designed to be welded to the pipe. Suitable for high-pressure applications. Slip-On Flanges: Easily slide over the pipe and are welded in place. Socket Weld Flanges: Used for smaller, high-pressure piping. Threaded Flanges: Attached without welding, ideal for low-pressure applications or pipes with a thin wall. Blind Flanges: Used to seal the end of piping systems or pressure vessel openings. Lap Joint Flanges: Used with stub end fittings for applications requiring frequent dismantling.

Request for a quote

COPIER MACHINERY

Netherlands

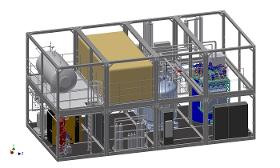

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

ERATEC

France

Preheating of forging tools Preheating of tubes before welding Preheating before thermal spraying Preheating of moulds

Request for a quote

MAGNITO EU LTD.

Bulgaria

Steel legs in X shape, cross welded steel pipes, powder painted, produced from rectangular steel pipe 30 mm x 60 mm, 1 unit heavy-duty metal plate with 12 holes. The base is equipped with adjustable leg leveling glides for perfect adjustment on the floor. All our products are Made in Europe.

Request for a quote

MAGNITO EU LTD.

Bulgaria

Training room table legs in T or C shape, welded construction, powder painted, steel pipe with diameter 51 mm, 1 unit heavy-duty metal plate with 10 holes. The legs are equipped with adjustable leg leveling glides for perfect adjustment on the floor. Possible delivery with casters for easy position change. 2 units in one set. All our products are Made in Europe

Request for a quote

MAGNITO EU LTD.

Bulgaria

T legs for training rooms, steel welded construction, powder painted, steel pipe with diameter 51 mm, 1 unit heavy-duty metal plate with 10 holes. The legs are equipped with adjustable leg leveling glides for perfect adjustment on the floor. Possible delivery with casters for easy position change. 2 units in one set. All our products are Made in Europe.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

We can supply pipes for the construction of pipelines, equipment and tanks subject to low temperatures as Seamless or welded pipes, hot rolled or cold finished. Pipe norms suitable for low temperatures are according to; ASTM A 333 / ASME SA 333 (seamless and welded pipes) EN 10216-4 (Seamless pipes) EN 10217-4 (Welded pipes)

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

Applications Pipes for the construction of pipelines for water, liquid hydrocarbons, natural gas and for the construstion of chemical and industrial plants, refineries etc. Norms Line pipes are according to the following norms: API 5L (ISO3183) (seamless and welded pipes) ASTM A53 / ASME SA53 (seamless and welded pipes) Manufacturing methods Seamless pipes, hot rolled or cold finished with following heat treatment: ERW pipes up to dia 24" and SAW pipes for the other sizes.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

We supply the pipes that are suitable for bending and are used for the constructions of plants and equipment subject to high temperatures and pressures. The seamless pipes, hot rolled or cold drawn/cold finished with heat treatment. The ASTM A335/ASME SA335 and EN 10216-2 norms require heat treatment also for the hot rolled pipes. The welded pipes are manufactured according to EN 10217-2. Supply of pipes suitable for high temperatures are according to; ASTM A 106 / ASME SA 106 (Seamless pipes) ASTM A 335 / ASME SA 335 (Seamless pipes) EN 10216-2 (Seamless pipes) EN 10217-2 (Welded pipes)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1019 series are lightweight cylinders where weight is of crucial importance. They were designed for the areas of mobile hydraulics, crane and aerial work platform construction. All cylinders work with low friction and are characterized by a stick-slip-free run. Lift and piston rod overhang are variable selectable. The cylinder connection is via plain bearing bushes. Connections are provided on the valve plate or a control block, which are flanged to the cylinder via welded pipes, in accordance with DIN EN 280. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the...

Request for a quote

CMPLAST

Poland

Is the second most frequently used metal after iron. It has high corrosion resistance in marine and industrial environments. It is characterized by high fatigue strength, it is susceptible to welding and anodizing. Aluminum is used in many industries mainly in shipbuilding, chemical, food, household appliances, architecture, construction and the automotive industry. It is used for elements of transport, for welded constructions, pressure tanks, piping elements, pneumatic and hydraulic lines. Details made of aluminum can be anodized and powder coated at your request

Request for a quote

ANTHERMO GMBH

Germany

Swept outlet similar to ANSI B 16.19 / ANSI B 36.10 Swept outlets in pipeline construction A swept outlet is used in pipeline construction just like a welding outlet, a socket welded outlet or a threaded outlet for a 90 ° branch. A swept outlet is an alternative to the T-piece / red. In comparison to the T-piece / Red.Tee, the installation effort for a swept outlet is lower because only one hole has to be drilled into a pipe. The swept outlet can then be welded into this hole. A swept outlet differs from a welding outlet in the type of welding. While a welding outlet is only placed on the run pipe and then welded, a swept outlet is welded directly into the run pipe. Ideal stress distribution Swept outlets were developed in order to achieve the best possible stress distribution for internal pressure and pipe forces. Due to the favorable voltage level, swept outlets are often used in highly stressed pipes in the oil and gas industry.

Request for a quote

KASAG SWISS AG

Switzerland

We bring your ideas to life KASAG has a high level of competence, with many years of experience in design and construction of plants, apparatuses, pressure vessels, pipes and welded structures. Our engineers can assist you with the following: Strength calculation according to the global regulations, such as PED (EN13445 / AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) FEM-calculations (Finite element analysis) and providing proof for overpressure and underpressure, load alteration, earthquake, joint flanges, nozzle loads Consultancy for interpreting and analyses of computation results, material choice, regulatory authorities Constructive, design based on Autocad 2D and Inventor 3D Comprehensive plants engineering, such as compilation of technical specifications, P&I schemes, risk analyses, pipeline/piping planning

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The different kinds of cold drawn tubes ready on stock cover a wide range of applications: COLD DRAWN SEAMLESS AND WELDED TUBES SUITABLE FOR HONING. COLD DRAWN SEAMLESS AND WELDED TUBES INSIDE H8. COLD DRAWN SEAMLESS TUBES FOR SHAFTS. WELDED SMOOTH BORE CYLINDER TUBES INSIDE H9 OR H10. COLD DRAWN SEAMLESS TUBES FOR HYDRAULIC AND PNEUMATIC POWER SYSTEMS. Seamless and Welded Cold Drawn pipes honed or ready for honing; H8, H9 or H10. STEELGRADES AND DELIVERY CONDITIONS COLD DRAWN / HARD (+C acc. EN 10305 / BK acc. DIN 2391) No heat treatment after final cold drawing. COLD DRAWN / SOFT (+LC acc. EN 10305 / BKW acc. DIN 2391) The final heat treatment is followed by a suitable drawing pass (limited reduction of area). STRESS RELIEVED (+SR acc. EN 10305 / BK+S acc. DIN 2391) After the final cold drawing process, tubes are stress relieved in controlled atmosphere in order to reduce work hardening due to the cold forming process. ANNEALED (+A acc. EN 10305 / GBK acc. DIN 2391) After...

Request for a quote

KAUFMANN GROUP

Slovakia

We provide extensive services in welding to a variety of industries. We specialize in pipe welding in refineries, boiler rooms, heating plants, food processing plants (dairies, etc.), air and water distribution in manufacturing halls and other industries. We use a wide range of welding methods including TIG, MIG/MAG (CO2 shielded), AC/DC (coated electrode) and flame welding.

Request for a quote

ANKARA BRONZ

Turkey

With a simple fusion, two parts can be combined. Large and heavy parts such as blocks and pipes can be welded using eutectic and tin-lead solder or melting alloys with low fusion points. CORROSION FEATURES Resistant to distilled, salty and fresh water. Affected by strong acids, alkalis and acid salts. Oxygen presence in solution increases response speed.

Request for a quote

WORLDWIDE MACHINING SPARE PARTS

Turkey

WELDING FEATURES With a simple fusion, two parts can be combined. Large and heavy parts such as blocks and pipes can be welded using eutectic and tin-lead solder or melting alloys with low fusion points.

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

This extremely robust flat-panel detector was specially designed for mobile use and the harsh conditions of industrial radiography and can be used with X-ray and gamma sources. The one-piece aluminum housing ensures maximum protection against external influences. It is also dust and waterproof and classified as IP67 according to IEC standard 60529. With its active area of 23.3 x 29.1 cm, excellent contrast and uniquely high resolution thanks to a pixel pitch of 76 µm, even the most demanding inspection tasks can be mastered. - Weld seam inspection - Pipe inspection, corrosion inspection, erosion inspection - Crack detection - Casting inspection

Request for a quote

HASS PIPE

Turkey

Spiral Welded Pipelines Related Values within the scope of the standard manufacturing program; Spiral welded steel pipe manufacturing capacity; Sheet thickness from 4 mm to 20 mm Spiral Pipe Diameter 200 mm up to 1727 mm, has a production capacity.

Request for a quote

HASS PIPE

Turkey

Sheet deep well pipes are made of St 37 material in accordance with DIN 1700 norms. Sheet drill pipes are assembled by welding to each other. It is resistant to underground reactions (collapses). Although the pipe weights cause an axial stress during the well lowering, both the pipe and the welding structure are strong enough to meet these loads. HASS Sheet Drilling Pipes are made of material conforming to TSE standards with wall thicknesses of 4 mm - 5 mm - 6 mm and are TSEK certified. Hass bridge type filter pipes are used to take precautions against silty in silty lands. Hass manufactures fittings such as reduction and pump flanges for Hass Sheet Drilling Pipes.

Request for a quoteResults for

Welded pipes - Import exportNumber of results

91 ProductsCountries

Category

- Pipes and tubes, steel (12)

- Welding, electric - equipment and supplies (6)

- Pipes and tubes, stainless steel (4)

- Animal Production (3)

- Laser - cutting and welding machines (3)

- Metallurgy and iron and steel industry - machinery and installations (3)

- Monitoring and control equipment (2)

- Pipe and tube fittings - ferrous metal (2)

- Pipe and tube fittings - non-ferrous metal (2)

- Steels and metals - welding and brazing (2)

- Temperature sensing devices (2)

- Agricultural machines and accessories (1)

- Air-conditioning systems, vehicles (1)

- Aluminium and aluminium alloys (1)

- Aluminium coatings (1)

- Brushes and paint brushes (1)

- Burners, industrial (1)

- Car tuning equipment (1)

- Components and parts for small household appliances (1)

- Computer furniture (1)