- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding machinery

Results for

Welding machinery - Import export

DOGRAR METAL

Turkey

Tube and section laser cutting provides many advantages such as new design opportunities, declining manufacturing steps or easier welding methods from machinery to furniture sector. Thanks to Trumpf TruTube 3000 Fiber that we have included in our machiner in 2021. we can process tubes and sections up to 170 mm diameter or side dimensions. Laser cutting of tubes and sections, used in a wide range from the machinery industry to the furniture industry, offers you new pipe and profile construction possibilities that cannot be realized with traditional methods in pipe and profile construction. All kinds of contours and shapes that cannot be made with traditional methods are achieved with laser with low tolerances and at the same time saving time. In addition to the ease of processing, you can also simplify further manufacturing steps with the created contours. For example, with the positioning aids obtained by creating male and female contours on opposite sides

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: Carbon steel: S235JR, S355JR Stainless steel: SS304, SS316 Aluminum alloy Process: Flame/plasma/laser cutting Punching/bending CO2 welding Machining Application: Agricultural & farm machinery Off-shore industry Construction equipment General machinery

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE inductive sensors for high mechanical loads still work trouble-free even after 10 impacts of 8 Joule. The sensor protected by a solid stainless steel sleeve is thus particularly resistant to shock and vibration. They are ideal for areas where standard sensors could be damaged mechanically. EGE offers variants resistant to high pressure cleaning with protection class IP 68/IP69 for use at temperatures up to 110° C and contamination-resistant sensors with PTFE coating. The proximity switches are based on the proven inductive principle and switch con tactless when a metallic object moves close. The sensors are particularly suited for heavy duty use, for example in metal processing, during welding and in mobile machinery.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc PCW Precision Circumferential Welder provide all of the features necessary to position and rotate parts for circumferential welding. Advantage: 1. The extreme accuracy welding lathe with servo motor control for turntable and transverse carriage. 2. Allow unskilled people to get high welding quality and consistently production progress. 3. Designed to enable horizontal or vertical configuration for more flexible welding solution. 4. ProArc offers a user-friendly and intuitive controller interface that allows users to implement the system quickly. 5. ProArc designed AVC (option) Enable to set the parameter of AVC in the integrated controller. 6. Motorize carriage on X axis (option) Ball screw drive system with dual linear guide way. * Positioning accuracy is +- 0.01mm * Travel speed 1 ~ 10,000 mm/min 5. Maximum through hole for diameter 80mm. *CE Conformity

Request for a quote

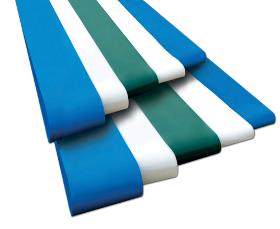

MAFDEL

France

MAFDEL designs and manufactures a large range of thermoweldable conveyor belts for industrial goods handling. They are suitable for a wide range of applications in many industries: food-processing, ceramics, wood, automotive, logistics, packaging... Manufacture in polyurethane or polyester elastomer, all the range is easy to weld on-site, without machinery dismantling. Compliant with the strictest standards, the food quality range improve the hygiene level in the food industries.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

-Dust protected strong mechanical structure -Feature of positioning welding head on 1,2 or 3 lines -Feature of oscillation on 1, 2 or 3 lines -Enable to work on different axis without mechanical adjustment -Enable to be used in Submerged,Inert gas or TIG -Enable to integrated with automations systems -“OLED” screen which all the parameters can be seen.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

It’s designed upon you weld cylindrical, conical and rectangle shaped bended frameworks and in shape of flat slab metal sheet and plaque linearly. Frameworks that are between 200-3000 mm diameters can be welded on different types of machines easily. Its production can be made from the length of 0.5 meter to 4 meters. Upon customer demand the length can be increased. As to application method, TIG, MIG and submerged welds can be adapted. Materials’ like boiler, thermosiphon, solar power boilers, cooling tanks, natural gas funnels, lpg tubes etc., height welds are made on this machine.

Request for a quote

KLN ULTRASCHALL AG

Germany

The device is used as hand pistol for riveting, welding and edge folding of plastic parts. The weight of the welding pistol is lower than 900 g. The optimum design of the welding pistol allow for a particularly comfortable handling. The titanium booster ensures a maximum safety of the converter and optimal adaptation to the various tools. Advantages of the SPK version: By the permanent cooling of the piezo-ceramic transducer and the titanium booster an extremely high performance period can be achieved. The cooling air pipe is integrated in the HF control cable. Advantage: No disturbing connective elements for a separate pipe, and the cooling air is led directly to the spots to be cooled.. For this the grip is fitted with an exhaust port for the cooling air, into which cooling pipes can be simply screwed in. In this version the generator is also cooled by an incorporated ventilator. As an option we can offer hand welding devices with energy control

Request for a quote

KLN ULTRASCHALL AG

Germany

The new generation of plastic welding machines of the OMEGA 4 series combines technical standards at the highest level with ease of use. The modular arrangement of the machine components, consisting of press, control and generator, enables easy adaptation to the respective plastic part and the respective location. Simple system operation is guaranteed with the multilingual touchscreen With this standard machine, even the most difficult welding tasks can be mastered reliably thanks to their performance and control and monitoring options. The A series is the basic version of the Omega. Time and energy measurement are available for process monitoring. Compared to the S-du X-series, the generator and control are combined. This makes the A-series more compact, but limits the number of welding modes and storable programs.

Request for a quote

KLN ULTRASCHALL AG

Germany

The LVW series covers smaller applications with machines of approx. 500 mm width and large applications up to a width of 2000 mm, like pallets, bumpers and more. As a principle our standard machines are equipped with an hydraulic lifting table. Depending on the machine size a contact force of up to 70 kN can be applied. This is necessary for large suction pipes made of PA 6.6 GV30 with heavy distortion or very large welding surfaces. Our vibration welders are fitted with our patented CPC system. This kind of regulation which is integrated in the converter stimulates the vibration unit with optimal resonance frequency. A low energy consumption is guaranteed during the friction phase. It is not necessary to enter the frequency parameter in the machine, as it is permanently “optimized”. This, the KLN drive systems are independent from the tool weight. The tool weight is solely limited in height, caused by the mechanical design and the high accelerating powers arising in these systems.

Request for a quote

KLN ULTRASCHALL AG

Germany

The new generation of plastic welding machines of the OMEGA 4 series combines technical standards at the highest level with ease of use. The modular arrangement of the machine components, consisting of press, control and generator, enables easy adaptation to the respective plastic part and the respective location. Simple system operation is guaranteed with the multilingual touchscreen With this standard machine, even the most difficult welding tasks can be mastered reliably thanks to their performance and control and monitoring options. The S series is the standard version of the Omega. An ultrasonic high-performance generator and and a separate control with a larger touch panel are available. There are also 12 program memories available. The separate control also enables the process data to be read, the travel distance to be measured and greater connectivity.

Request for a quote

KLN ULTRASCHALL AG

Germany

Basically the TOOLMASTER versions vary by their tool design, their size of useable surface and the degree of automation. All versions are suitable for high temperatures and optionally equipped with fire protection engineering, which quickly separates the tool in case of energy drop or timeout. KLN also manufactures special machines adapted to your individual requirements. TOOLMASTER "Basic" as well as type HE 50/30 are standard machines. The versions "Advance", "Semi-Automatic" and "Automatic" are made with tools in sandwich design. This makes possible the handling of upper tool, hot plate element and lower tool as a compact unit. They are designed particularly for quick and frequent production changes. The HE/SA has a horizontal concept with servo-drive technology for quick and precise movements. The TOOLMASTER CC has been developed for applications with two welding tasks in one cycle. Almost all machine versions can be provided with pneumatic or servo-motor drives.

Request for a quote

KLN ULTRASCHALL AG

Germany

The new generation of plastic welding machines of the OMEGA 4 series combines technical standards at the highest level with ease of use. The modular arrangement of the machine components, consisting of press, control and generator, enables easy adaptation to the respective plastic part and the respective location. Simple system operation is guaranteed with the multilingual touchscreen With this standard machine, even the most difficult welding tasks can be mastered reliably thanks to their performance and control and monitoring options. The X series is the premium version of the Omega series. This series is also equipped with a proportional valve for a defined pressure control. In addition, this Omega series has a pneumatic pressure / counter pressure system and thus ensures smooth movement even at low pressure.

Request for a quote

KLN ULTRASCHALL AG

Germany

The REK-B offers all advantages of the high technical level of the OMEGA III series, particularly regarding precision and reliability. The machine may be integrated in an automatic production line and controlled via a higher-ranking control system (PLC). Options: • Hydraulic oil brake • Working table • Housing • Light curtain • Rotary table • Control of external periphery Advantages: • Easy programming via touch panel TP 270 • Display of time-travel curve and pressure-time curve after the welding cycle on a graphic display with plain text. • Regulation of the welding forces via proportional valve technology. • The machine REK-B offers many possibilities for analysis, control and regulation. • Three welding models in order to meet the requirements of each application • Positioning of the spin head prior to and after the welding process • Display of the ongoing process parameters ( welding travel, -time).

Request for a quote

WESTWOOD FOX

United Kingdom

High Quality & Durable - Gloves' leather material is very soft, quite comfortable and safe for wearing. Multipurpose Versatility - Tough leather is nonslip and wear-resisting, suitable for cycling driving protection, welding labor protection, machinery assembly, gardening, welding, flame cutting, climbing, carrying, cutting, mechanical operation work, etc. Upgraded Version - Superior Non-slip Grip - Harmless, wearing comfortable, sweat-absorbent, flexible and breathable. Durable gunn cut for comfortable wearing and good fit. Reinforced Protection with Palm Patch - Perfect cowhide gloves for gardening, protect your palms and wrists from dirt, dust, mud and impurities, from scratches and broken nails or other injuries.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Welding construction as required No matter whether pipes, small parts or large components - the welding construction department of Siempelkamp Maschinenfabrik GmbH is able to fulll your wishes thanks to its high-performance machinery. Our welding specialists are able to produce your components using MIG, MAG, UP, TIG, Emanual and electro-slag processes. Numerous certicates attest to the highest quality of our welding work. Key features procedure: MIG, MAG, UP, TIG, E-manual, electro-slag Component weight up to 100 t Pipe forming up to Ø168.3 mm Pipe neck up to Ø270 mm Advantages procedure: MIG, MAG, UP, TIG, E-manual, electro-slag Component weight up to 100 t Pipe forming up to Ø168.3 mm Pipe neck up to Ø270 mm Application of the most ecient welding process for your component Highest quality standards through certied welding work economic production of tubes by our forming and necking machine

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Welding machinery - Import exportNumber of results

18 ProductsCountries

Company type

Category

- Welding, plastics - machinery (7)

- Electron beam welding - equipment (2)

- Laser - cutting and welding machines (2)

- Steels and metals - welding and brazing (2)

- Active electronic components (1)

- Compactors and crushers (1)

- Conveyor belts (1)

- Gloves (1)

- Sensors (1)

- Welding work - steels and metal (1)

- Welding, electric - equipment and supplies (1)