- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wood conveyors

Results for

Wood conveyors - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

As with the paper industry, because of the geographical location of TCM - THOMAS CONSTRUCTIONS MECANIQUES in the heart of the Vosges woodlands, the wood processing industry is the third key industrial sector that has driven our growth. Among many other customers, we work with the leading manufacturers of MDF panels and reels for the storage and transport of electrical cables Beyond special machinery, this collaborative work has helped us to develop specialist expertise in : the upgrading of existing production plants to reduce set-up and adjustment times and increase productivity conveyor systems wood cutting systems (sawing) wood sanding systems wood nailing and assembly systems Applications and projects : conveyor systems wood cutting systems (sawing) wood sanding systems wood nailing and assembly systems robotic units Related operations on customers’ sites : maintenance of equipment and infrastructure repairs

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The long-wood line is designed for processing logs with lengths between 3 and 8 meters and diameters between 50 and 850 mm: With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient disc chippers, the production of high-quality chips is guaranteed. Key features Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of logs Buer capacity of up to 30 minutes/ 80 metric tons bone dry material Step feeder for absolutely consistent volumes Metal sensor and roller conveyor cleaning system Rotor debarker for eective debarking even at extremely low winter temperatures Robust drum chipper Advantages Highly controllable wood feed Ecient debarking Perfect chip quality thanks to the adjustability of to the feed material mixture Minimal ne material content High lling level and high utilization of chipper c High operational safety

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

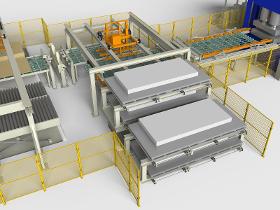

Papers and carrier boards are combined in the batch laying section. In the simplest of cases, a batch that is ready for pressing consists of a sheet of decorative paper as the base layer, a carrier board and a sheet of decorative paper as the top layer. It may in certain circumstances be necessary to use of several types of paper. Features, function Papers soaked in resin are supplied to the plant in sheets lying on pallets. A suction bar separates the papers from the stack and pulls them on to a laying conveyor. A suction carriage delivers the board made from wood-based material. The laying conveyor conveys the batch from laying station to laying station / conveys the assembled batch to the facility core. The batch is statically charged in order to secure the papers on the carrier board for continued transport. Advantages The individual layout of the batch layer is based on coordinated standard modules.

Request for a quote

FÖRDERTEC GMBH

Germany

Screw conveyors primarily comprise a U-shaped trough and the worm shaft with blades. They are primarily used for internal transportation of bulk goods (filter cake, pellets, wood). Our standard screw conveyors are manufactured with pedestal bearings and gland seals. The construction forms for material transport can be selected with a pitch of between 0° and 90°. The construction length can be varied depending on requirements. The materials for the screw conveyors can be supplied in normal steel and wear-resistant steel; plastic panels are also possible.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Wood conveyors - Import exportNumber of results

4 ProductsCountries

Company type