- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cylinder liner

Results for

Cylinder liner - Import export

ALKIM PETROKIMYA

Turkey

AKSOIL MARINE OIL LC SERIES high quality base oils and state-of-the-art additives Highly alkaline vessel produced with a special combination of packages engine cylinder oil. It is used in the cylinders of low speed crosshead ship engines using heavy diesel fuel (high sulfur). Thanks to the special dispersants in its formula, balanced with the additives that regulate the cleaning and acidity, it provides a superior cleaning on the cylinder liners, piston rings and the bottom of the piston.

Request for a quote

ECOROLL AG WERKZEUGTECHNIK

Germany

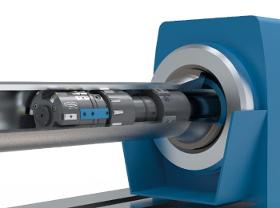

ECOROLL's OMEGA system combines skiving and roller burnishing for machining hydraulic cylinders and cylinder liners. While the OMEGA skiving head cuts the cylinder's inner surface to the exact size and form required, the roller head burnishes it. The simultaneous skiving and burnishing process has almost completely replaced honing as the alternative machining process, since it is much more economic and faster. Thanks to its modular design, customized tools can be configured based on pipe quality and machining length. Sometimes for various reasons, tubes have to be skived and burnished separately or both processes have to be carried out one after the other. Therefore, all SK skiving heads can be delivered also as separate tools. SK skiving heads are then used in conjunction with GZ roller burnishing tools. In the first pass the SK skiving head peels the cylinder, and in the second pass the GZ tool burnishes it smooth.

Request for a quote

MAINTENANCE PARTNERS

Belgium

The service range that we provide for reciprocating compressors allow you to benefit from the expertise and skills developed by our workshops and field service teams. 24 – hour service Repairs Engineering Compressor Audits Parts supply Field service Relocations Full general overhauls Maintenance Contracts Condition monitoring Used machinery Technical consultancy WORKSHOP ACTIVITIES Complete overhauls of reciprocating compressors Cylinder liner replacements Bearing repairs Crankshaft repairs Pistonrod repairs by HVOF spraying Crosshead repairs Conrod repairs Parts supply by reverse engineering or supplied by OEM Valves & stuffingboxes overhauls ENGINEERING Upgrades Re-rating Piston rod drop system Hydrocom system FIELD SERVICE Minor and Major overhauls of reciprocating compressors Provision of Supervisors, technicians and mechanics required to perform the activities Turnkey jobs Toolcontainers Troubleshooting Emergency interventions

Request for a quote

MAINTENANCE PARTNERS

Belgium

PRODUCT RANGE Reciprocating compressors Plunger compressors INGERSOLL-RAND – BORSIG – DRESSER RAND – WORTHINGTON – LINDE – MANNESMAN – THOMASSEN – ALLEY – FIVES-LILLE – NUOVO PIGNONE – BELLIS & MORCOM – IHI – CLARK – BURCKHARDT – COOPER The service range that we provide for reciprocating compressors allow you to benefit from the expertise and skills developed by our workshops and field service teams. 24 – hour service Repairs Engineering Compressor Audits Parts supply Field service Relocations Full general overhauls Maintenance Contracts Condition monitoring Used machinery Technical consultancy WORKSHOP ACTIVITIES Complete overhauls of reciprocating compressors Cylinder liner replacements Bearing repairs Crankshaft repairs Pistonrod repairs by HVOF spraying Crosshead repairs Conrod repairs Parts supply by reverse engineering or supplied by OEM Valves & stuffingboxes overhauls ENGINEERING Upgrades Re-rating Piston rod drop system Hydrocom system FIELD SERVIC E Minor and Maj

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The BDW is designed to reface the seating provided in the engine block for receiving the flange of the cylinder liner. Capacity Refacing diameter range 90-180mm Features Centering in the cylinder bore is automatically effected by simply turning the centering spindle. The studs at the engine block are used for rigidly clamping the BDW to the engine block. The seating is refaced to the preset depth by the simultaneous application of both a rotary and a transverse feed motion to the single point cutting tool. While the single point carbide cutting is rotated around the seating, a feed gear mechanism ensures a transverse feed motion. An adjustable depht stop makes sure that all seatings are cut to the same depth.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The HMB Honing Rigs are designed for honing cylinder liners removed from the engine block with the corresponding mobile Hunger PHM Honing Machines. - Honing Rig Type HMB 340 is tailored to the Honing Machine Type HBM 340. - Honing Rig Type HMB 640 is tailored to the Honing Machine Type HBM 640. Features Rigid base structure including upright supporting tubes for mounting the mobile PHM Honing Machine. The liner to be honed is placed on top of a honing liquid reservoir which is slideably mounted on the base structure. The reservoir can be drawn out for ease of loading and unloading of the cylinder liner by means of a crane. An electric pump is provided to supply honing liquid to a spray nozzle. The spray nozzle is mounted on a magnetic base which can be attached to the frame tube to direct the honing liquid to the area to be honed.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application With the mobile honing machine PHM, the cylinder liners of large diesel engines can be honed in the crankcase when installed. The stationary honing machine base HMB is required for honing removed cylinder liners. An optional comfort control panel including the regulator valves and the manometer gauges can be provided at the lower end of the preassembled drive unit within easy reach of the operator while standing at cylinder liner level. A single central air treatment unit with air filter and lubricator is also provided for trouble free operation. Automatic stroking is available as a option. The stroking lenght can be adjusted by means of end stops.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The Hunger SHM is designed for precision honing of cylinder liners with bore diameter from 150 to 640 mm. Features • Air powered honing. Powerfull air motor for rotary motion of honing head, air hoist for stroke motion and, as an unique feature, air cylinders for stone feeding. • Superior control. Manual buttons are provided for fine adjusting setting of honing head RPM, stroking rate and stone feeding pressure. • Pressure gauges for displaying the selected setting of honing head RPM, stroking rate and stone feeding pressure. • Two-hand control actuation to protect the operator according to the stringent EC safety regulations. • Automated stroking between adjustable end stops. • Drawer-type honing liquid reservoir acting as support for the cylinder liner and mounted on casters for ease of loading and unloading the cylinder liner.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The RCM is designed for refacing - the landing surface for the cylinder liner on the engine block, - the landing surface for the cylinder head on the cylinder liner - the landing surface for the cylinder liner on the cylinder head. Capacity Refacing diameter range 200 - 720mm Features The RCM is fitted with two motors providing a smooth cutting action. The speed of the motors is infinitely variable so that the cutting speed can be adapted to the diameter and material of the landing surface. A separate power supply unit is provided for ease of operation. A small hand-held remote control is supplied so that the operator can conveniently switch on and off the machine while watching the refacing operation. The remote control includes an emergency stop to stop the machine in case of emergency. The RCM is centered by a pilot tailored to the specific engine component to be serviced.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VD4HD-RC is designed for refacing • the landing surface for the cylinder liner on the engine block, • the landing surface for the cylinder head on the cylinder liner and • the landing surface for the cylinder liner on the cylinder head. Features Drive unit and gear head of the VD4HD-RC are identical with the drive unit and gear head of the VD4HD Valve Seat Refacing Machine. If you have already a VD4E machine and you want to use it with our new face turning heads, we can convert it into the new high performance VD4HD System. The three available face turning heads should be used according to our recommendation with the VD4HD drive unit and the related power supply type 4HD. We would be glad to advise you about our new VD4HD system and send you an offer for this. The D4/0° adapter head is bolted to the gear head in place of the valve seat refacing head. The VD4HD-RC is centered by a pilot assembly which is designed to fit to the engine component to be serviced.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

The new portable HUNGER universal refacing machine UDM4E is a versatile machine offering a choice of modular components for refacing valves and valve seats as well as counterboring seat ring pockets and resurfacing the sealing surfaces on cylinder heads, cylinder liners and engine blocks of large diesel and gas engines. Key features: - No abrasive dust. A fast clean cut, - Compact and handy design - Modular add-on components provide a flexible solution for multiple projects - Powered by SELV (Safety Extra Low Voltage) to avoid risk of electrical shock - Power supply with universal AC input - Fast set-up time - Easy to use - The economical solution for both field and workshop use »Roundness, concentricity and surface finish of the refaced faces are within manufacturers’ specifications or even better«

Request for a quote

RUHFUS SYSTEMHYDRAULIK GMBH I.L.

Germany

Cylinder Components By components we mean fully mechanically machine parts not only for hydraulics but also for other industries and applications. These include cylinder liners manufactured in peeled and rolled versions or with honed inside surface, with trunnions, flanges, fork heads, bearing eyes or other connections. But also associated piston rods, pistons and rod guides as well as also for example guiding columns for plastic injection moulding machines, tie rods for hydraulic jacks, rollers for paper machines etc. Our product range has increased many times over. Please send us the drawing of your parts. We will give you our opinion and make you an attractive offer.

Request for a quoteResults for

Cylinder liner - Import exportNumber of results

14 ProductsCountries

Category

- Construction - Machines & Equipment (3)

- Paint mixers and grinding machines (2)

- Turning - steels and metals (2)

- Construction - portable power tools (1)

- Cylinders, hydraulic (1)

- Filtering equipment and supplies (1)

- Gas, compressed (1)

- Import-export - oil (1)

- Offshore services (1)

- Polishing - steels and metals (1)